Miter cutting head, Miter position lock, Self-centering vise – Wilton FK350-4 User Manual

Page 8: Fk350 controls, Fk350-sx controls, Trigger handle, Flood coolant system, Features

8

Features

Miter Cutting Head

The miter cutting head is the unit that cuts the

material and consists of a cast iron base, blade

support unit and guard, transmission unit, and

motor. The depth of cut is set by adjusting the

depth cut stop. The miter cutting head swivels

and locks into -45º, 90º, and +45º by means of a

locking mechanism. Depressing the mechanism

overrides the lock, permitting the head to adjust

to any position between -45º and +45

q.

Miter Position Lock

The miter position lock secures the miter cutting

head from movement. The miter is secured

when the lock is pushed all the way to the left

and can be positioned when the lock is moved to

the right.

Self-centering Vise

The self-centering vise holds the work piece in

place during cutting. The work piece is secured

in the vise by turning the vise handles.

FK350 Controls

The control panel consists of the Power (On/Off)

switch and High/Stop/Low switch, and an

integral coolant system. To operate the

machine, the Power switch must be set to on

and the High/Stop/Low switch must be set for Hi

or Low. Then depress the trigger handle to start.

FK350-SX Controls

This machine features a 2-speed motor, feed

speed control, an integral coolant system, and

two modes of operation; manual mode, and

semi-automatic mode. In semi-auto, the

complete cut cycle is initiated via push button.

The semi-auto cut cycle closes the vise

clamping the material, powers the head down

completing the cut, then raises the head, and

opens the vise. In manual mode, head up/down,

and vise open/close is initiated by switches.

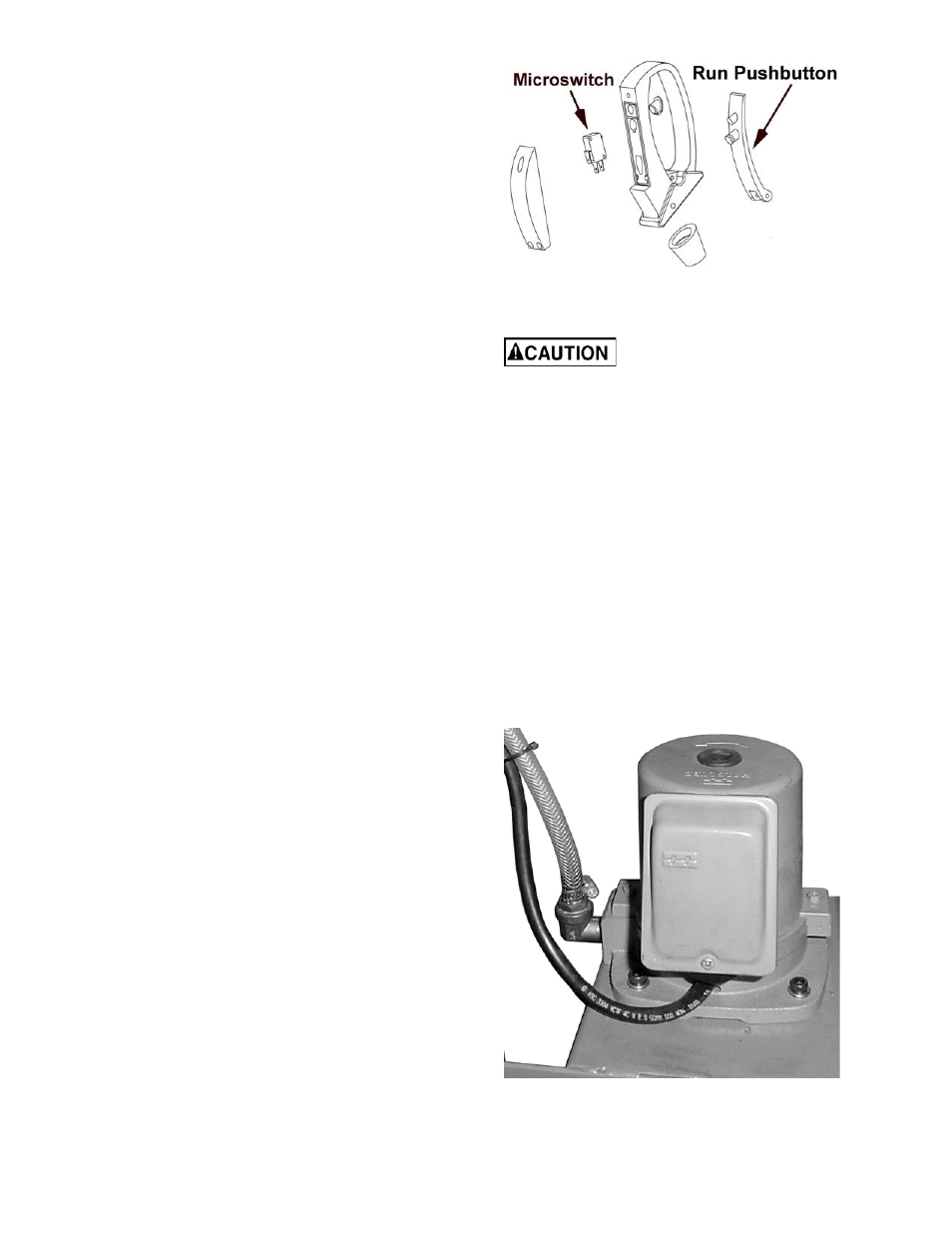

Trigger Handle

The trigger handle (Figure 1) is located on the

operating lever used to raise and lower the saw.

It contains a micro-switch, which is activated

when the operator depresses the run trigger.

Figure 1

Flood Coolant System

The coolant pump must be

submerged before operating to prevent

damage to the pump.

Coolant is dispensed directed onto the saw

blade from a coolant fitting on the upper blade

guard. Coolant is provided through tubing from

the coolant pump (Figure 2) in the machine

base.

Adjust the coolant flow valve on coolant fitting to

achieve desired flow. When the coolant switch is

in the ON position, flow starts when the drive

motor is started. Turning off the coolant switch

stops coolant flow.

This coolant system can operate with either a

soluble oil base coolant or water-soluble

synthetic coolant. Coolant should be changed

regularly. Some recommended brands are DoAll

and Lenox. These coolants are available at your

local industrial distributor.

Figure 2