Assemble block, Continued) – Weil-McLain 80 User Manual

Page 7

• Installation • Start-Up • Maintenance • Parts

7

Part No. 550-141-935/0602

Install intermediate sections

Sections are top heavy. Unbolted sections may fall if not

supported, resulting in severe personal injury or death.

1. Remove and discard

3

/

8

" diameter shipping tie rods.

2. Remove grit from port machined surfaces with clean rag.

Do not use petroleum-based cleaning or sealing compounds

in boiler system. Severe damage to system components can

result, causing substantial property damage.

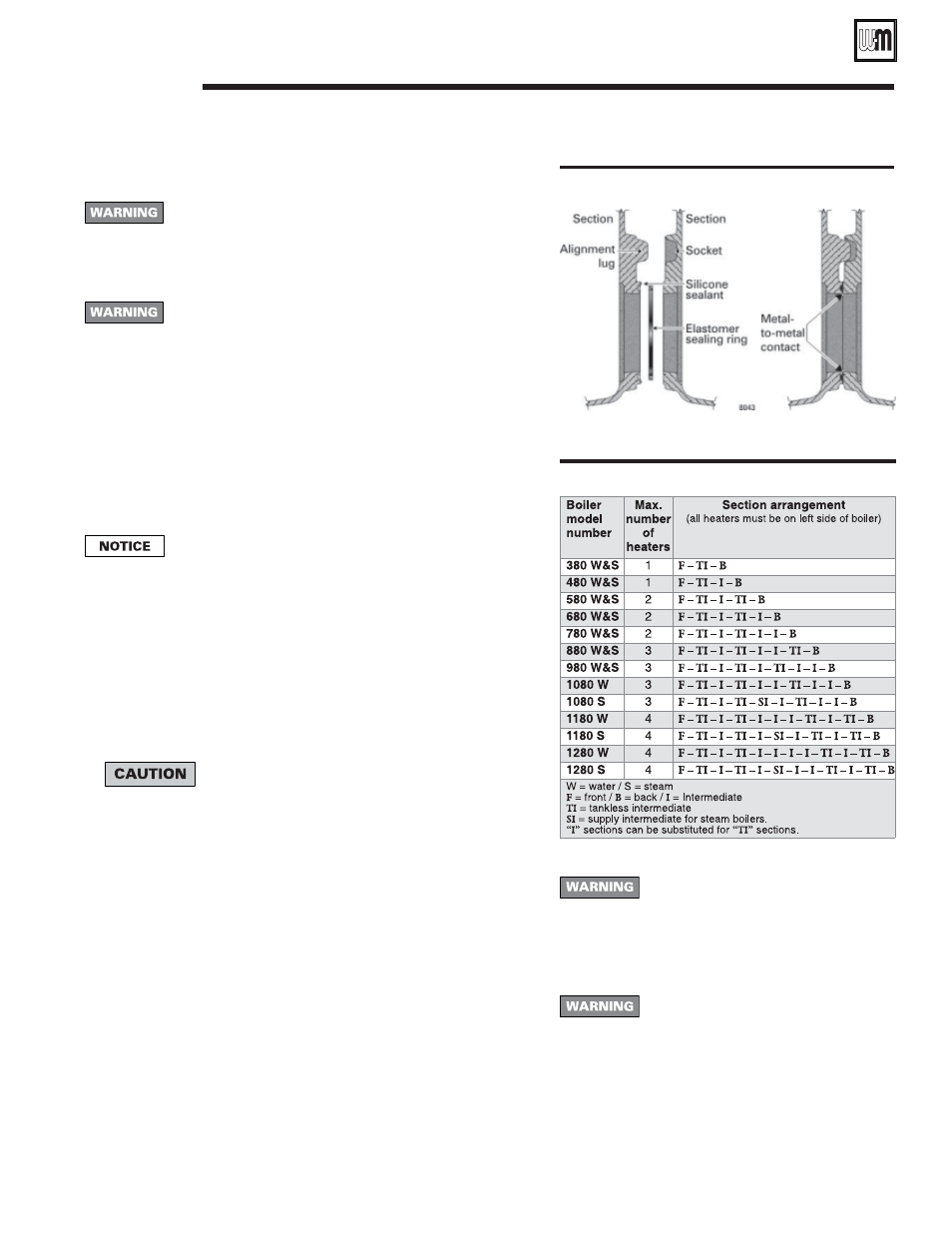

3. Position intermediate section so aligning lugs fit into sockets of next section.

See Figure 6.

4. Install TI (tankless intermediate) and SI (supply intermediate) sections

(when used) in order shown in Table 3.

5. Draw sections together until metal-to-metal contact is made around

machined port openings (see Figure 6):

a. Oil threads on 4 draw rods. Install washer and nut on end to be tightened.

Use nut only on other end.

b. Uniformly draw sections together, starting at washer/nut end.

Important

— Leave an equal amount of thread on each end

of the draw rod. This is needed to allow securing the jacket

support brackets in place (see pages 20 and 21).

c. Draw rods should be torqued to a range of 90 to 100 ft. - lbs. Do not

back off draw rods.

d. Metal-to-metal contact will be achieved around port openings. See Figure

6. If gap occurs, it should be no greater than .032". Check with feeler

gauge.

e. If, for any reason, gap around machined port opening exceeds .032",

check for rope extending from rope grooves, dirt on port openings or

sockets, or misaligned lugs. If corrections are made and gap still exists,

contact your Weil-McLain distributor or sales office before continuing

installation.

6.

After erecting first intermediate section, check both

sections for plumb. Failure to plumb sections can cause

misaligned piping and breeching, possibly resulting in

property damage.

7. Repeat steps 1-5 from “Prepare back section,” page 6.

Assemble block

(continued)

3

Figure 6

Sealing ring installation and port alignment

Table 3

Section arrangement

Prepare remaining sections

1. Follow “Prepare intermediate section” for remaining intermediate and front

sections:

a. Remove any grit from threads inside tapped holes with clean rag.

Install bottom refractory blanket on combustion

chamber floor inside section block

1. Unroll blanket only to depth of back section and first intermediate section.

2. Spread adhesive on bottom side of blanket.

3. Press blanket into center bottom of sections.

4. Unroll and install blanket per steps 2 and 3 as each intermediate and front

section are installed.

5. At front section, cut off blanket 2 ½" from burner opening. Discard unused

blanket.

Do not use petroleum-based cleaning or

sealing compounds in boiler system.

Severe damage to system components can

result, causing substantial property

damage.

b. Check each section for proper sealing rope position

before proceeding to next section.

Failure to position sealing rope properly

can cause boiler to not seal gas-tight. Gas

tight seal prevents possible flue gas leakage

and carbon monoxide emissions,

resulting in severe personal injury or

death.

If using tankless heater (TI) sections

1. Install tankless heaters and gaskets or heater cover plates

and gaskets. Use

3

/

8

" x

3

/

4

" studs, washers and nuts.