Install flue collector, Flue collector assembly, Install collector hold-down bolts – Weil-McLain 80 User Manual

Page 10: Prepare flue collector hood assembly

Weil-McLain 80 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners

10

Part No. 550-141-935/0602

Install flue collector

6

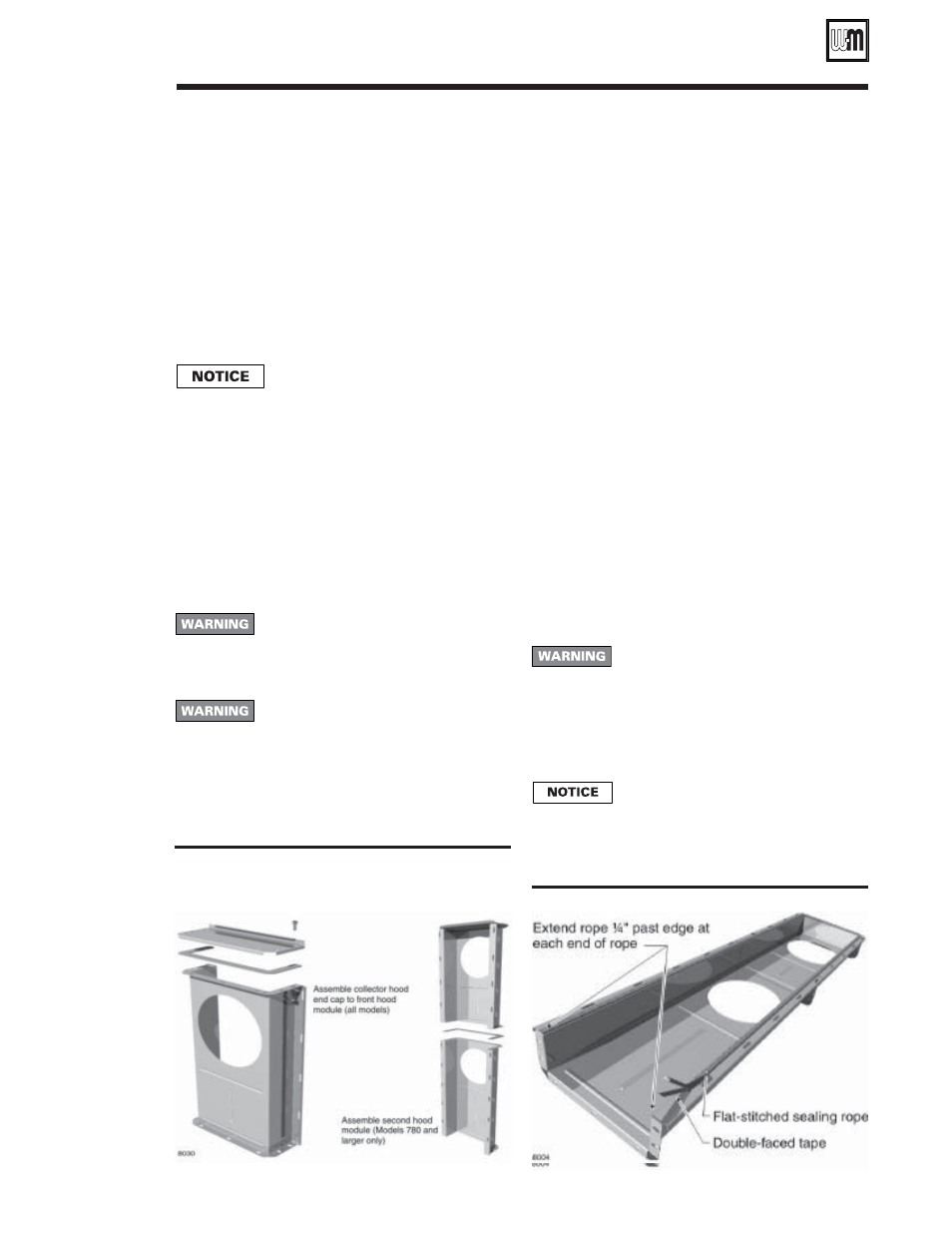

Figure 8

Collector hood preparation

Figure 9

Flue collector sealing rope installation

Flue collector assembly

1. Figure 10, page 11, shows flue collector components

and locations. Figure 11, page 13, shows collector hoods

for all models. Follow all instructions in this manual to

ensure correct installation of the flue collector.

2. Model 80 boilers are available with either rear flue or

top flue. Verify that you have the correct components

for your application. You can convert a Model 80 from

rear to top or top to rear flue using a flue conversion

kit, available from your Weil-McLain distributor.

The flue outlet for top flue models must

be located as shown in this manual.

Install collector hold-down bolts

1. Figure 10, lower left — Install a collector hold-down

bolt assembly at each section joint, and on both sides

of the boiler section assembly. Set aside the flanged nuts

for securing the collector assembly when it is ready.

2. Each hold-down bolt assembly consists of a

5

/

16

" x 2"

carriage bolt, flat washer, regular hex nut and a flanged

nut as shown.

Prepare flue collector hood assembly

Make sure gaskets are intact, not torn or

otherwise damaged. These conditions can

cause possible flue gas leakage and carbon

monoxide emissions, resulting in severe

personal injury or death.

The boiler contains ceramic fiber and

fiberglass materials. Use care when

handling these materials per instructions

on page 38 of this manual. Failure to

comply could result in severe personal

injury.

1. Stand flue collector hood front module (item 4) on end

as in Figure 8, left side.

2. Wipe all flanged surfaces with clean rag.

3. Lay flue collector hood gasket (item 2) on flange.

4. Place flue collector end cap (item 1) on gasket. Align

bolt holes. Secure with seven

5

/

16

" x

5

/

8

" flanged bolts

and flanged nuts. Tighten to between 30 and 35

inch-pounds torque.

(See

WARNING

on page 12, top

right column.)

5. For 880 - 1280:

a. Stand remaining hood module on end, as in

Figure 8, right side.

b. Wipe all flanged surfaces with clean rag.

c. Lay gasket on flange.

d. Carefully place open end of first module on top of

gasket, aligning flanged surfaces.

e. Secure with seven

5

/

16

" x

5

/

8

" flanged bolts and

flanged nuts. Tighten to between 30 and 35 inch-

pounds torque.

(See WARNING on page 12.)

6. Attach flat-stitched sealing rope to hood assembly. See

Figure 9:

a. Lay hood on floor with flanged side up.

b. Wipe flanged surface with clean rag to remove dirt

and oil.

c. Apply double-faced tape to flanged surface.

d. Apply rope to tape beginning on one side of open

end of hood, leaving ¼" extending past edge. Bend

rope around corners. DO NOT cut or stretch

rope

.

Do not pre-cut rope. All collector hood

joints must be sealed gas-tight to prevent

possible flue gas leakage and carbon

monoxide emissions, resulting in severe

personal injury or death.

e. Continue around entire flange. At other open end,

leave ¼" rope extending past edge of flange. Cut off

excess rope.

Double-faced tape serves only to hold

sealing rope in place during installation.

It will disintegrate over time. If collector

hood and sealing rope are removed for any

reason, install new tape and new gasket.