End bearing brackets, Center bearing bracket, Spring assembly – Wayne-Dalton 8500 User Manual

Page 10

Please Do not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer,

refer to your local yellow pages business listings or go to the find a Dealer section online at www.wayne-dalton.com

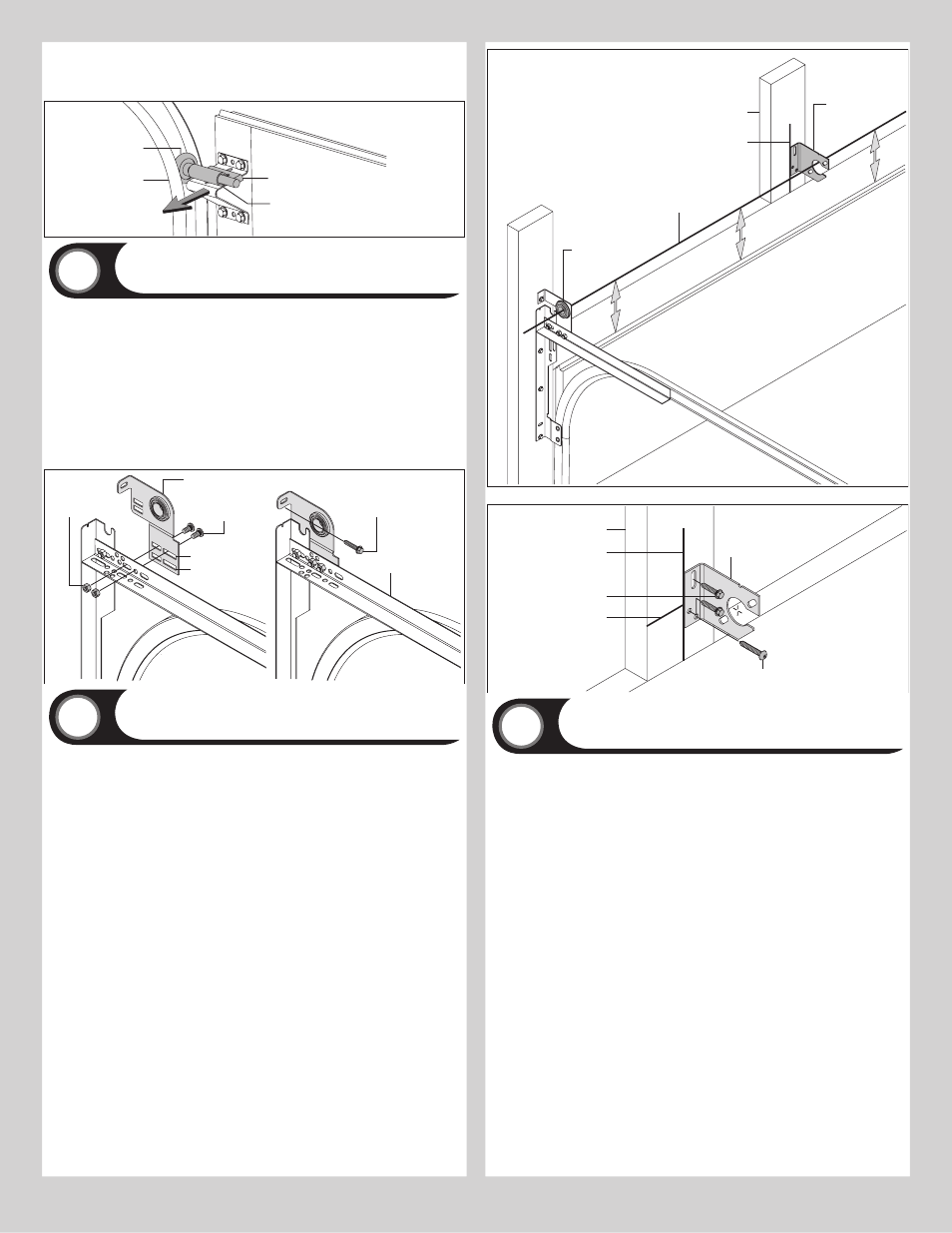

If your windload option code is 0124, secure all of the door’s rollers with 7/16” push nuts by

placing a push nut onto the end of each roller and sliding it toward the end hinge or bracket.

Leave at least 1/4” of space between push nut and end hinge or bracket.

Top bracket slide

5/16”-18

Flange hex nut

Horizontal track

Roller

Top section

End Bearing Brackets

20

Tools: Step ladder, Power drill, Ratchet wrench, 7/16” Socket driver,

9/16” Socket, 9/16” Wrench

IMPORTANT: RIGHT AnD LEfT HAnD IS ALWAYS DETERMInED fROM InSIDE THE BuILDInG

LOOKInG OuT.

NOTE: End brackets are right and left hand.

Break the end bearing brackets apart. Attach the left hand end bearing bracket through either

the end bearing bracket’s upper or lower slots to the left hand horizontal angle using (2)

3/8”-16 x 3/4” truss head bolts and (2) 3/8”-16 nuts.

IMPORTANT: THE EnD BEARInG BRACKET’S LOWER SLOTS ARE uSED On DOORS WITH

12” RADIuS TRACK; THE uPPER SLOTS ARE uSED On DOORS WITH 15” RADIuS TRACK.

Secure the top of the end bearing bracket to the jamb with (1) 5/16” x 1-5/8” lag screw.

Repeat for other side.

(2) 3/8”-16

Hex nuts

(2) 3/8”-16 x 3/4”

Truss head bolts

Left end bracket

Upper slots

Lower slots

Horizontal angle

(1) 5/16” x 1-5/8”

Lag screw

Center Bearing Bracket

20

Tools: Step ladder, Power drill, 7/16” Socket driver, 1/4” Torx bit, Level,

Tape measure, Pencil

Locate the center of the door. Mark a vertical pencil line on the mounting surface above

the door, at the center. Measure from the center of the bearing, in one of the end bearing

brackets, downwards, to the top the door. using that measurement, measure that distance

upwards from the top of the door to the mounting surface, and mark a horizontal pencil line

which intersects the vertical pencil line. Align the edge of the center bearing bracket with

the vertical pencil line and the center of the bearing in the center bearing bracket with the

horizontal pencil line; this is to ensure the torsion tube is level between the center and end

bearing brackets.

Attach the center bearing bracket to the mounting surface, using (2) 5/16” x 1-5/8” lag

screws and (1) 5/16” x 2” tamper-resistant lag screw.

IMPORTANT: USe A 5/16” x 1-5/8” TAMPeR-ReSiSTAnT LAg ScReW inSTeAD of THe

5/16” x 2” TAMPER-RESISTAnT LAG SCREW If MOunTInG SuRfACE IS MOunTED OVER

MASOnRY. TAMPER-RESISTAnT LAG SCREW MuST BE ATTACHED THROuGH THE BOTTOM

HOLE Of THE CEnTER BEARInG BRACKET.

Center bearing

bracket

Vertical line

Mounting surface

Equal distance (top of door section to horizontal line)

Horizontal line

Center of end

bearing bracket

Center bearing

bracket

(1) 5/16” X 2” or (1) 5/16” x 1-5/8”

Tamper-resistant lag screw

(2) 5/16” x 1-5/8”

Lag screws

Vertical line

Mounting surface

Horizontal line

spring Assembly

21

Tools: Step Ladder

IMPORTANT: RIGHT AnD LEfT HAnD IS ALWAYS DETERMInED fROM InSIDE THE BuILDInG

LOOKInG OuT.

NOTE: Identify the springs provided as either right hand wound (red winding cone), which

goes on the LEfT HAnD SIDE or left hand wound (black winding cone), which goes on the

RIGHT HAnD SIDE.

facing the inside of the door, lay the torsion tube on the floor. Lay the spring with the black

winding cone and the black cable drum at the right end of the tube. Lay the spring with the

red winding cone and the red cable drum at the left end of the tube.

NOTE: The set screws used on all torsion winding cones and cable drums are now colored

red. DO nOT identify right and left hand by the set screw color.

Slide the nylon center bracket bushing onto the torsion tube followed by the springs and

cable drums. The nylon center bracket bushing, springs, and cable drums must be positioned

as shown. With assistance, pick up the torsion assembly and slide one end of the torsion

tube through one end bearing bracket. Lay the middle of the torsion tube into the center

bearing bracket and slide the other end of the torsion tube into the other end bearing

bracket. Position the torsion tube so that equal amounts of the tube extend from each end

bearing bracket.

10