Piping connections, Eg, peg, egh g, 4 — b – Weil-McLain EG User Manual

Page 9

Part Number 550-110-639/0703

9

EG, PEG, EGH G

AS

-

FIRED

B

OILERS

—

SERIES

4 — B

OILER

M

ANUAL

Piping connections

2

Pipe before installing controls. Connect return piping

after jacket is attached. Connect supply piping before or

after jacket is attached.

Failure to properly pipe the boiler may

result in improper operation and damage

to the boiler or building.

Forced hot water boilers and

gravity hot water boilers

(EG Only)

1. To protect:

• radiant panels, plaster, etc. from high temperature water

supplied from boiler, or

• boiler from condensation caused by low temperature

water returned from system.

2. To protect boiler from condensation formed by low

water temperature returned from large water content

converted gravity systems, etc., see Figure 4, page 6.

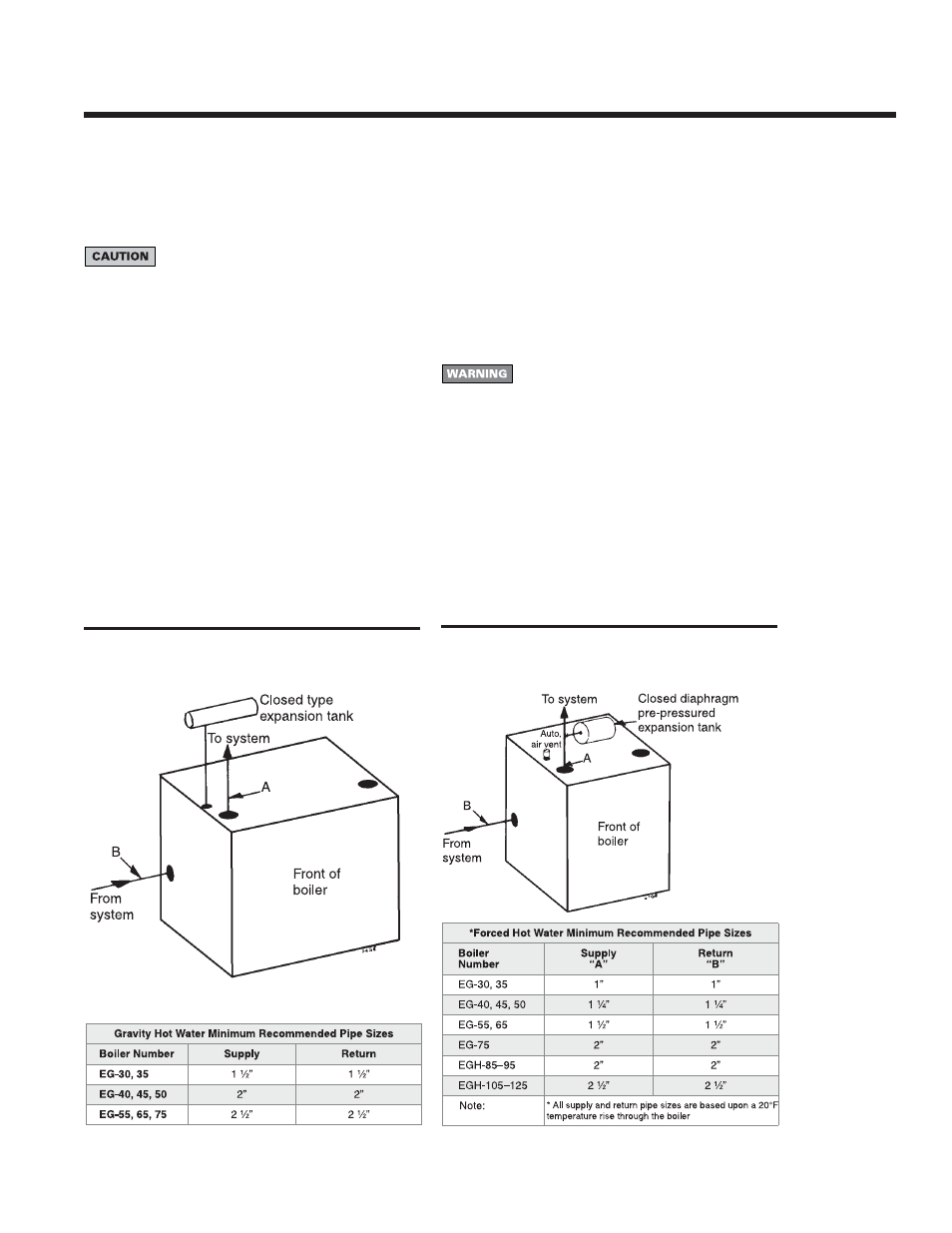

Refer to tables and Figures 11a and 11b.

1. Circulator must be selected and sized according to

the design requirements of the system. Size expansion

tank to handle the volume of water in the system.

2. Small expansion tanks cause system water to be lost

from relief valve. Make-up water is then added

Figure 11a Recommended piping connections

forced hot water boilers with closed

type expansion tanks

Figure 11b Recommended piping connections

forced hot water boilers with

diaphragm type expansion tanks

through fill valve. Eventual section failure can result.

Expansion tank installation:

a) Closed type expansion tank - connect from the 3/4"

N.P.T. tapping on left end section to expansion tank

using 3/4" N.P.T. piping. Any horizontal piping must

pitch upward toward tank at least 1 inch per 5 feet of

piping.

b) Diaphragm type expansion tank - may be located

anywhere in the system, preferably near the boiler. Install

automatic air vent as shown in Figure 11b.

3. Install water relief valve vertically in “E” tapping.

Relief valve discharge piping must be piped

near floor close to floor drain to eliminate

potential of severe burns. Do not pipe to

any area where freezing could occur. Do

not plug, valve or place any obstruction in

discharge line.

4. Connect system return piping to left end for EG -

right or left for EGH. Supply and return must be on

same end of EGH boiler, for proper flow and

disposition of water throughout the sections.

5. Installer must provide drain cock(s).

6. Connect cold water fill supply piping close to boiler.

7. Plug all unused tappings.