Piping connections – Weil-McLain EG User Manual

Page 10

Part Number 550-110-639/0703

10

EG, PEG, EGH G

AS

-

FIRED

B

OILERS

—

SERIES

4 — B

OILER

M

ANUAL

Piping connections

(continued)

2

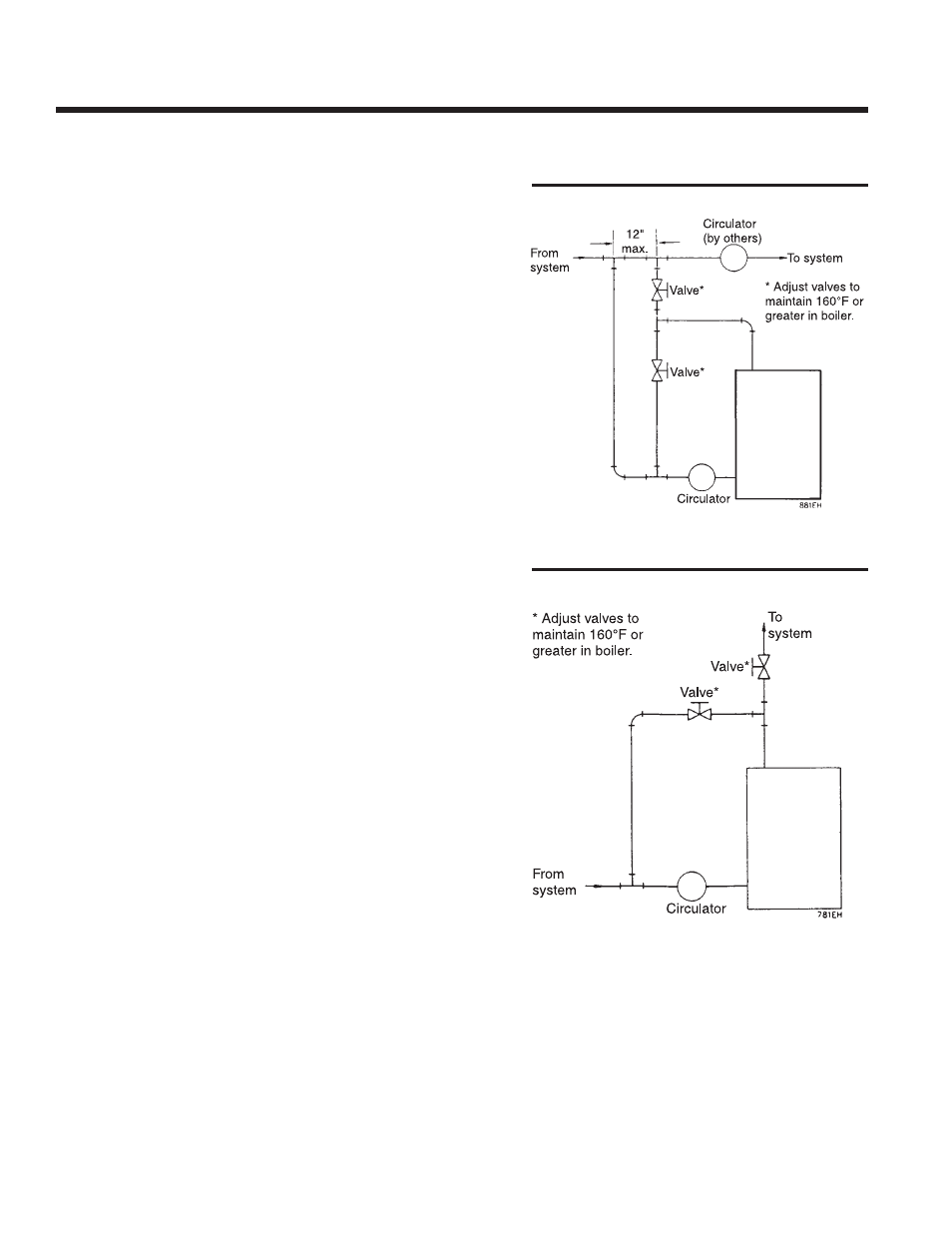

Bypass piping

BYPASS PIPING IS NOT NORMALLY REQUIRED ON

ANY BASEBOARD SYSTEM

Bypass piping should be used for the following

installations. Bypass, supply, and return piping should

be same size.

1. See Figure 12 to protect:

• radiant panels, plaster, etc. from high temperature

water supplied from boiler, or

• boiler from condensation caused by low temperature

water returned from system.

2. See Figure 13 to protect boiler from condensation

formed by low water temperature returned from large

water content converted gravity systems, etc.

Use with refrigeration systems

The boiler must be installed so that chilled medium is

piped in parallel with the heating boiler with appropriate

valves to prevent the chilled medium from entering the

boiler. See Figure 14. Consult I=B=R Installation and

Piping Guides.

If boiler is connected to heating coils located in air handling

units where they can be exposed to refrigerated air, gravity

circulation during the cooling cycle must be prevented

with flow control valves or other automatic means.

8. Multiple Zoning

a) Zone valves:

Refer to zone valve manufacturer’s literature for wiring

and application. A separate transformer is required to

power zone valves.

Provide balancing valves to adjust the flow so it is about

the same in each zone.

b) Circulators:

Zoning with circulators requires a relay for each circulator.

Install flow control valves to prevent gravity circulation.

Provide balancing valves to adjust the flow so it is about

the same in each zone.

9. If system is to be ASME inspected and approved, an

additional high temperature limit is needed. Purchase

and install the control in supply outlet piping from

boiler.

Figure 12

Figure 13