Service, Eg, peg, egh g, 4 — b – Weil-McLain EG User Manual

Page 21

Part Number 550-110-639/0703

21

EG, PEG, EGH G

AS

-

FIRED

B

OILERS

—

SERIES

4 — B

OILER

M

ANUAL

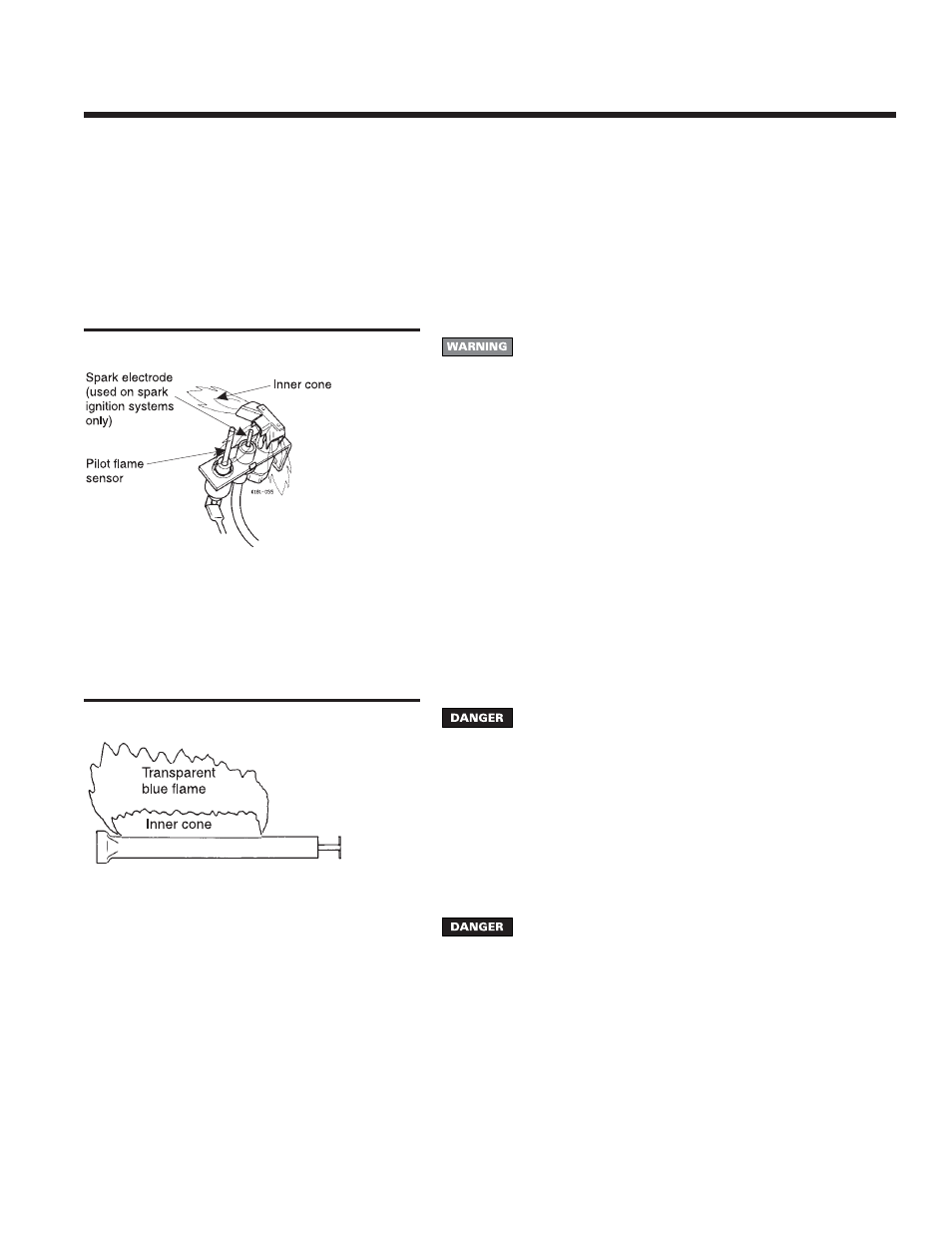

Check pilot burner flames

1. Proper pilot flame

a) Blue flame.

b) Inner cone engulfing pilot flame sensor.

c) Pilot flame sensor glows cherry red.

Service

(continued)

9

functioning properly. If flame blows out or flickers drastically, vent system

must be checked for obstructions or other causes of improper venting.

2. Inspect all parts of venting systems for deterioration from corrosion, physical

damage, sagging, etc. Correct all conditions found.

3. Verify damper is open when burner ignites. For additional information, see

Control Supplement.

Clean boiler heating surfaces

The boiler contains ceramic fiber and fiberglass materials. Use

care when handling these materials per instructions on page 19 of

this manual. Failure to comply could result in severe personal

injury.

1. Follow shut-down procedure

2. Disconnect breeching and remove damper (if used) and draft hood.

3. Remove upper rear jacket panel. Turn back jacket insulation to expose collector

hood.

4. Remove collector hood. Clean excess boiler cement from collector hood and

cast iron sections.

5. Remove burners from base of boiler. Follow “Cleaning main burners” to

thoroughly clean burners. Place newspaper in base of boiler to collect soot

that will fall.

6. With a wire flue brush, clean between the sections.

7. Remove paper and soot. Vacuum or brush base and surrounding area.

8. Replace collector hood. Seal with boiler cement.

9. Replace draft hood, damper (if used) and breeching.

10. Replace insulation and jacket panel.

11. Replace main burners.

When replacing, burner tubes must be seated in slots in back

burner support with openings face up. Gas orifices must inject

down center of burner. Failure to properly seat burners will result

in severe personal injury, death or substantial property damage.

12. Follow “To Place in Operation” procedure.

NOTE: Excessive sooting indicates improper gas combustion. Call a qualified

service agency or your local gas utility to check for proper combustion and make

any necessary adjustments.

Cleaning main burners

1. Vacuum or brush burners to remove dust and lint.

When replacing, burner tubes must be seated in slots in the back

with openings face up. Gas orifices must inject down center of

burner. Failure to properly seat burners will result in severe

personal injury, death or substantial property damage.

Annual shut-down procedure

1. Follow correct lighting/operating instructions on boiler.

2. Do not drain system unless exposure to freezing temperatures will occur. If

antifreeze is used with system, do not drain.

3. If complete boiler and piping system must be drained to avoid freezing,

provide method to drain water from both ends of boiler at or below return

tapping level.

Figure 24

Typical pilot burner flame

Figure 25

Typical main burner flame

2. Improper pilot flame.

a) Overfired - flames large and lifting or blowing past pilot

flame sensor.

b) Underfired - flame small; pilot flame sensor not engulfed

by inner cone.

c) Lack of primary air - flame tip yellow.

d) Pilot flame sensor not heated properly.

Check main burner flames

1. Proper burner flame - Yellow-orange streaks may

appear - caused by dust.

2. Improper flame:

a) Overfired - Flames large.

b) Underfired - Flames small.

c) Lack of primary air - Yellow tipping on flames; sooting

will occur.

Inspect venting system

1. Check venting system at least once a month during

heating season. With boiler firing, hold candle or match

below lower edge of draft hood “skirt”. If flame does

not blow out, but burns undisturbed, vent system is