Installation, Eg, peg, egh g, 4 — b – Weil-McLain EG User Manual

Page 5

Part Number 550-110-639/0703

5

EG, PEG, EGH G

AS

-

FIRED

B

OILERS

—

SERIES

4 — B

OILER

M

ANUAL

Installation

(continued)

Installation clearances

Suggested minimum clearances for servicing

•

24 inches for cleaning and servicing, left side.

•

18 inches for access to controls and components, front.

•

46 inches from top for cleaning flueways.

•

6 inches on remaining sides.

Required minimum clearances to combustible material in

alcove installations

Top 46"

R. Side 4"

Front: Alcove

Rear 6"

L. Side 4"

EGH 105-125:

Provide service clearances listed above and minimum 24"

between jacket and any combustible wall(s) and ceiling.

Install in space large in comparison to size of boiler.

•

Single wall vent pipe must be at least 6 inches from combustible material.

•

Type "B" double wall metal vent pipe - refer to vent manufacturer's

recommendation for clearances to combustible material.

•

Hot water pipes must be at least ½" from combustible material.

Residential garage installation

Install boiler so burners are at least 18 inches above the floor.

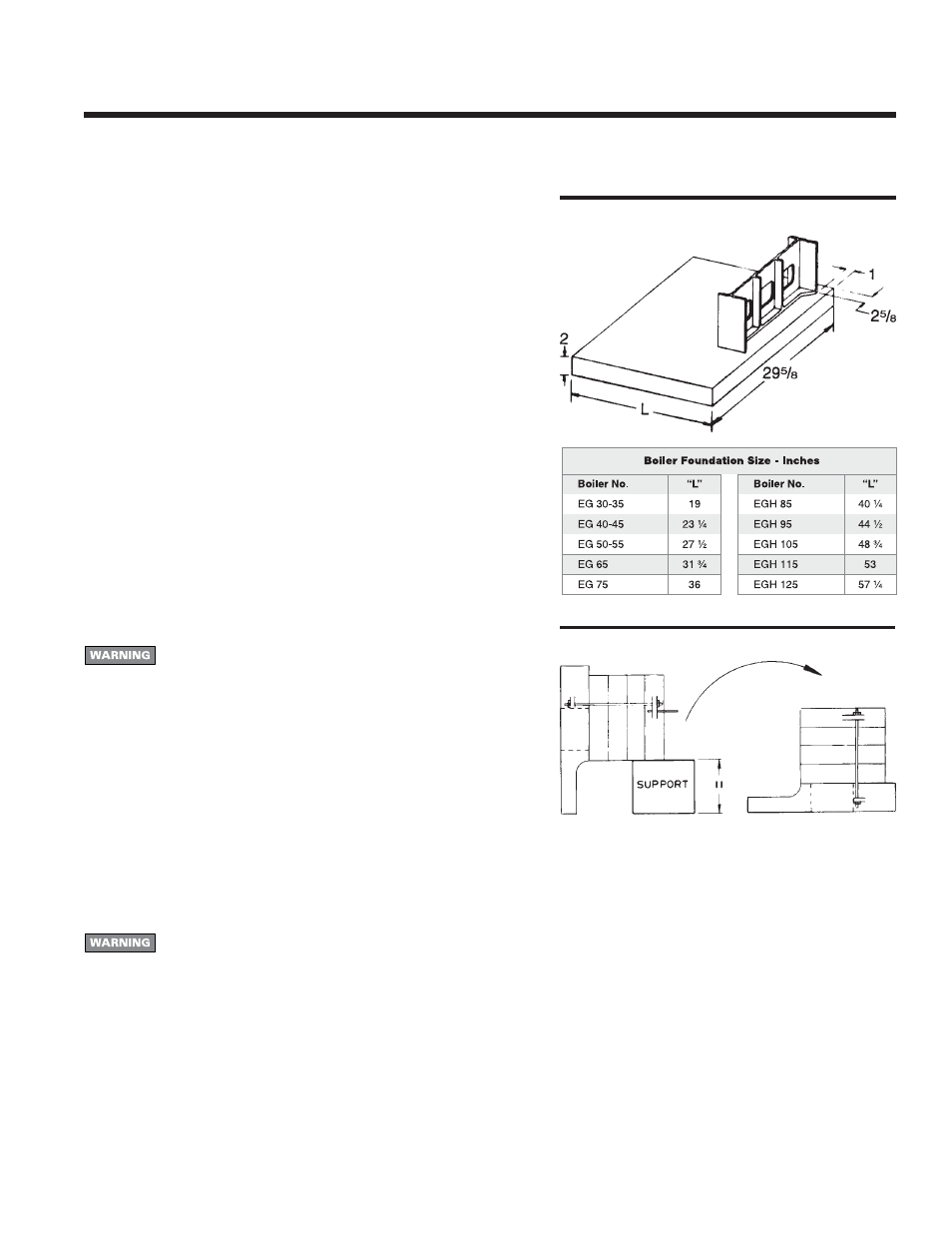

Boiler foundation

Never install boiler on combustible flooring or carpeting, even if

a concrete or aerated foundation is used. Severe personal injury,

death or substantial property damage can result.

1. See Figure 1. A level concrete or solid brick pad is required if:

a) There is a possibility of the floor becoming flooded.

b) Non-level conditions exist.

2. An aerated boiler foundation is recommended if any of the following

conditions exist:

a) Electrical wiring or telephone cables buried in the concrete floor of the boiler

room.

b) Concrete floor is "green."

c) There is a history of the floor becoming flooded.

d) Water is channeled under the concrete.

1

Placing the boiler

Block assembly is extremely heavy. Handle with caution to avoid

personal injury.

Where the EGH block assembly is taken apart for handling:

1. Put a support under center of block. Support must be within 1/2 inch of

block bottom.

2. Remove short center draw rods.

3. Tip half blocks on end as shown in Figure 2. Save elastomer sealing rings and

cope seal between sections.

Figure 1

Boiler foundation

4. After moving half-blocks into desired location, clean

port surfaces with clean, dry rag. Do not use oil. Place

sealing rings in recessed ports. Place cope seal in section

grooves.

5. Re-assemble block in reverse order. When drawing

sections together, use 45 ( ± 5) ft-lbs torque.

Installation of optional indirect

water heater

For a boiler ordered with internal type indirect water heater,

remove heater opening cover plate (water boilers - round

plate on left side; steam boilers - rectangular plate on front).

Install heater(s) as shown on pages 13. Do not over tighten

studs and nuts - damage to the gasket can occur..

Figure 2