Installation, Warning improper unit lift – Trane WPWD User Manual

Page 11

WSHP-SVX02A-EN

11

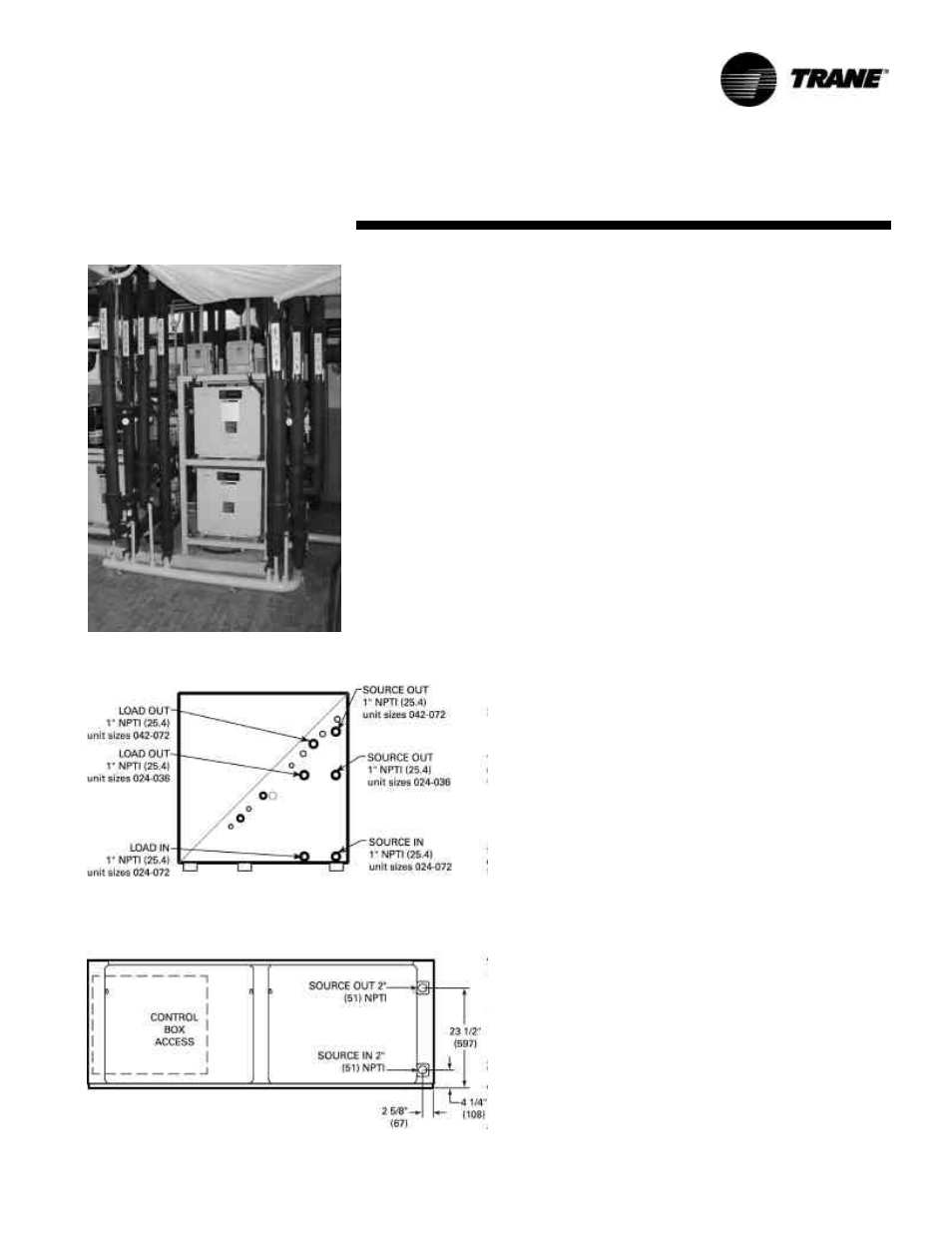

Figure 2: Racking installation

WARNING

Improper Unit Lift!

Test lift unit approximately 24

inches to verify proper center of

gravity lift point. To avoid

dropping of unit, reposition lifting

point if unit is not level. Failure to

properly lift unit could result in

death or serious injury or possible

equipment or property-only

damage.

Unit Placement

Units may be placed into a field sup-

plied mechanical rack (See Figure 2),

or placed on a finished floor. Loosen

compressor bolts to release tension of

the rubber grommets to help reduce

vibration during operation. Sound

proofing material (field supplied) is

recommended to help attenuate noise

generated by compressor vibration.

It is important to leave appropriate

clearances around the unit to achieve

maintenance and

serviceability to

the equipment.

See page 6 for

service clearance

dimensions.

Water Connection

Connect the source-side and load-side

water-in/water-out from the water-to-

water heat pump to the source system

and the load system.

Note: The source for a water-to-water

heat pump is typically a boiler/cooling

tower or geothermal loop.

The load for a water-to-water heat

pump is typically fresh-air unit(s), fan

coil(s), hydronic coil(s), radiant heat,

wall fin, or potable water.

The source and load connections for

the 2-ton through 6-ton equipment is

on the right hand side of the unit.

The 20-ton equipment incorporates

the source-side connection at the

unit’s front, and the load-side connec-

tion at the unit’s back.

For vibration isolation, it is recom-

mended that flexible steel braided

hoses be installed instead of hard pip-

ing the equipment to the main loop

system or mechanical device.

Trane offers 4-types of hose kit varia-

tions:

• Stainless steel braided flexible

hose with manual shut-off (ball)

valves

• Stainless steel braided flexible

hose with manual deluxe shut-off

(ball) valves

• Stainless steel braided flexible

hose with manual circuit-setter

valve

• Stainless steel braided flexible

hose with automatic balancing

valve

Additional accessories, such as a

strainer are recommended for use to

eliminate contaminants from entering

the brazed-plate or co-axial water-to-

refrigerant heat exchangers.

Installation

Figure 3: Water connection