Danger, Warning – Toshiba VF-nC1 User Manual

Page 22

E6581090

A-13

1

1.4.4 Installation

■

Installation environment

The VF-nC1 Inverter is an electronic control instrument. Take full consideration to installing it in

the proper operating environment.

Danger

Prohibited

• Do not place any inflammable substances near the VF-nC1 Inverter. If an accident

occurs in which flame is emitted, this could lead to fire.

Mandatory

• Operate under the environmental conditions prescribed in the instruction manual.

Operations under any other conditions may result in malfunction.

Warning

Prohibited

• Do not install the VF-nC1 Inverter in any location subject to large amounts of

vibration.

This could cause the unit to fall, resulting in bodily injury.

Mandatory

• Check to make sure that the input power voltage is +10%, -15% of the rated power

voltage written on the rating label (

±10% when the load is 100% in continuous

operation)

If the input power voltage is not +10%, -15% of the rated power voltage (

±10%

when the load is 100% in continuous operation) this may result in fire.

Prohibited

• Avoid operation in any location where there is direct spraying of the following

solvents or other chemicals. The plastic parts may be damaged to a certain degree

depending on their shape, and there is a possibility of the plastic covers coming off

and the plastic units being dropped.

• If the chemical or solvent is anything other than those shown below, please contact

us in advance.

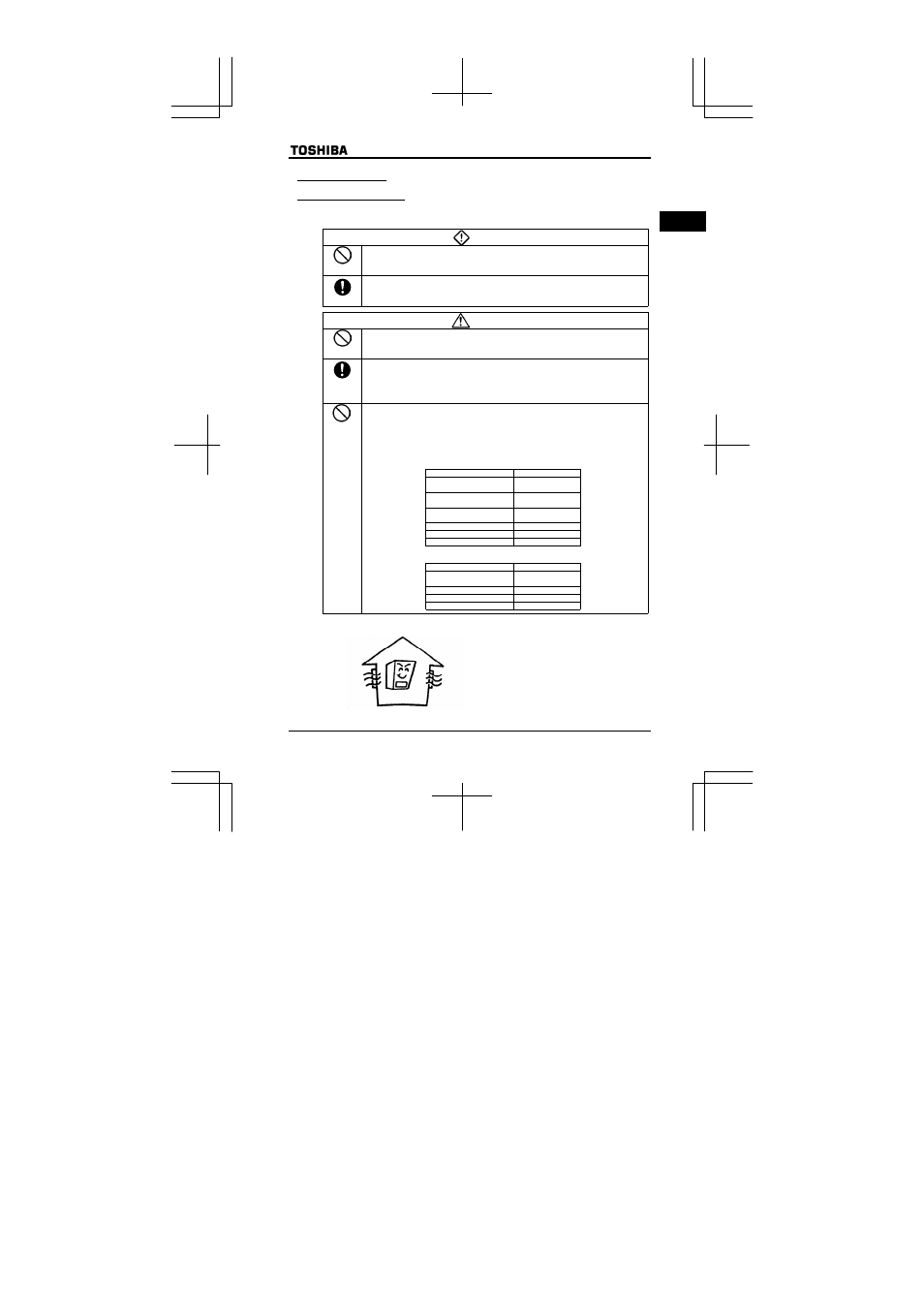

(Table 1) Examples of applicable chemicals and solvents

(Table 2) Examples of unapplicable chemicals and solvents

Note: The plastic cover has resistance to deformation by the above applicable

solvents. They are not examples for resistance to fire or explosion.

• Do not install in any location of high

temperature, high humidity, moisture

condensation and freezing and avoid

locations where there is exposure to water

and/or where there may be large amounts

of dust, metallic fragments and oilmist.

• Do not install in any location where

corrosive gases or grinding fluids are

present.

Chemical

Solvent

Hydrochloric acid

(density of 10% or less)

Methanol

Sulfuric acid

(density of 10% or less)

Ethanol

Nitric acid

(density of 10% or less)

Triol

Caustic soda

Mesopropanol

Ammonia

Glycerin

Sodium chloride (salt)

Chemical

Solvent

Phenol

Gasoline,

kerosene, light oil

Benzenesulfonic acid

Turpentine oil

Benzol

Thinner