Taylor SLUSH 382 User Manual

Page 7

3

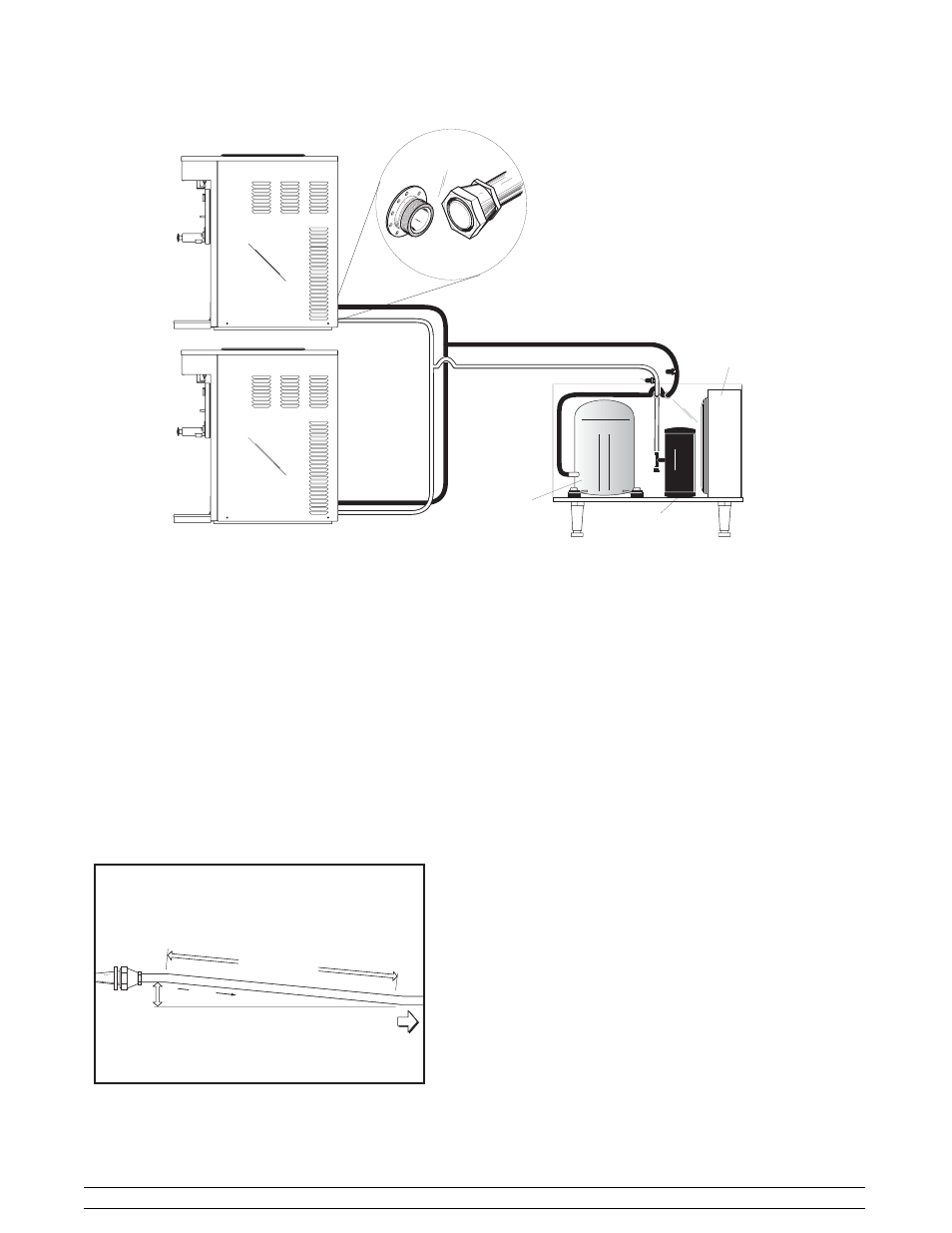

Models 382/RC25

To the Installer

Note: 5/8” individual line lengths are not to exceed 75 ft. (22.8 m) maximum length each.

Total line length is not to exceed 150 ft. (45.7 m). 5/8” line + 5/8” line + 3/4” line = 150 ft. or less.

Figure 2

Compressor

Condenser

Liquid Refrigerant

Reciever

CONDENSING UNIT

Access Valve

DISPENSER UNIT

382

DISPENSER UNIT

382

Installation

Step 1

Install refrigeration lines from the dispenser to the

condensing unit. Do not create oil traps.

Note: For proper oil return, installation of horizontal

suction lines are to be sloped downward in the

direction of the condensing unit. The slope must be a

minimum 1/4” (6.4 mm) angle per 10 ft. (30.48 mm) of

line length.

FROM

DISPENSER

TO CONDENSER

¼" (.64 cm)

FLOW

10'-0"

(3.048 m)

Figure 3

Normally, any straight run of tubing must be supported

near each end of the run. Long runs require additional

supports. As a guide, 3/8” to 3/4” copper should be

supported every 5 ft. (1.5 m). When changing

directions, no corner should be left unsupported.

Supports should be placed a maximum of 2 ft. (.61 m)

in each direction from the corner. If soft copper tube is

used, make sure it is not kinked or flattened. If hard

drawn copper tubing is used, use only long radius

elbows.

Step 2

Braze the supplied quick connect/disconnect

couplings on the dispenser end of the refrigeration

lines. Couplings are supplied with the dispenser.

Step 3

Braze the quick connect/disconnect couplings and

access tees on the condensing unit end of the

refrigeration lines. Couplings and access tees are

supplied with the unit.

Note: Wrap a wet cloth around the brass coupling

bodies to prevent heat damage to the seal.

Step 4

Test the field constructed lines for leaks.