Table 6. ped matrix – Toshiba Density (Consistency) Meter LQ500 User Manual

Page 9

LQ500

9

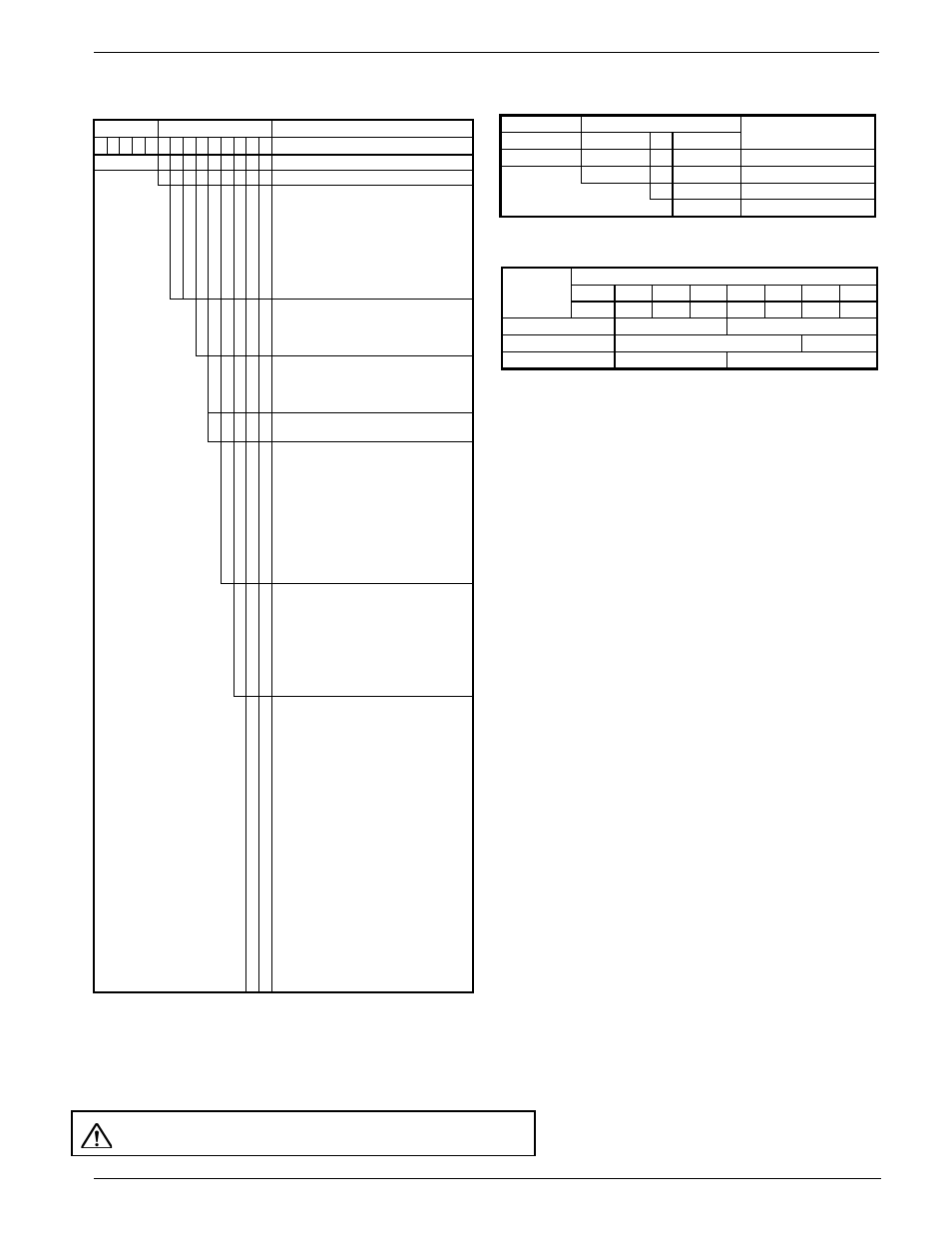

Table 4. Type Specification Code

(LQ500 Density (consistency) Meter)

TYPE CAT

Code

SPECIFICATION

1 2 3 4 5 6 7 8 9 10 11 12 13 14

L

Q

5 0 0 Microwave

Density

(Consistency)

Meter

A Standard

Meter Size

0 5 50mm (2")

0 8 80mm (3")

1 0 100mm (4")

1 5 150mm (6")

2 0 200mm (8")

2 5 250mm

(10")

3 0 300mm

(12")

Mounting Style

B JIS

10K

flange

connection

C ANSI

150

flange

connection

F DIN

16

flange

connection

Purpose

A Standard

B for

PED

(150

to

300

mm

(6" to 12") for EU) (Note 1)

C for

UL/CUL

Hazardous

locations

type

Wetting parts

A SCS14A

cast

(Equivalent

to

316L

SS) pipe (standard)

B SCS14A

cast

(Equivalent

to

316L

SS) pipe with teflon PFA coating for

sticky application

C SCS14A

cast

(Equivalent

to

316L

SS) pipe for abrasive application

(Note 2)

D Hastelloy C pipe

Cable

length

between

detector

(RF part) & converter

A 10

m

(32.8

ft)

(standard)

B 20 m (65.6 ft)

C 30 m (98.4 ft)

D 40

m

(131.2

ft)

E 50

m

(164

ft)

X None (Note 3)

Optional specifications

None

(standard)

(blank

codes

are

required.)

A B Pipe buffing type

A

C

-20

to

50

deg.C

(-4

to

122

deg.F)

environment temperature

specification, 200 to 240 Vac power

supply type of LQ500

A

D

Pipe

buffing

type

with

-20

to

50

deg.C (-4 to 122 deg.F) environment

temperature specification, 200 to 240

Vac power supply type of LQ500

A

E

-20

to

50

deg.C

(-4

to

122

deg.F)

environment temperature

specification, 100 to 120 Vac power

supply type of LQ500

A

F

Pipe

buffing

type

with

-20

to

50deg.C (-4 to 122deg.F)

environment temperature

specification, 100 to 120 Vac power

supply type of LQ500

Note 1: The specification of PED (Pressure Equipment

Directive) is required from 150 to 300 mm (6" to

12") when the installation location is in the Europe.

Note 2: The differences between standard type are RTD

sensor and Applicator window.

Note 3: Toshiba recommends to using our specified cable.

Table 5. Type Specification Code

(AF900 Hand-held Terminal)

Model Specification

Code

1 2 3 4 5 6 7 8 9 10 11 12

Description

A F 9 0 0

Hand-held terminal

L Q 3

For use with LQ series

A

Display language English

A A 3

Standard

Table 6. PED matrix

Meter Size

mm 50 80 100 150 200 250 300

Flange

inch 2 3 4 6 8 10 12

DIN16 SEP Certified

DIN10 SEP

Certified

ANSI150 SEP

Certified

SEP: Not required the PED.

Certified: The PED is certified.

Check your flange type and its meter size of the LQ500

whether it corresponds to the PED or not when its

installing location is in the Europe.

If yes, you need to choose the code “B” at the 10th

column in the specification code (Table 4)

Specifications are subject to change without notice.

Printed in Japan 2006-11 (TDOC)

© TOSHIBA Corporation 2003

All Rights Reserved.

Misuse of this product can result in damages to property or human injury.

Read related manuals carefully before using this product

.

ISO9001 and ISO14001 are certified.