Toshiba Density (Consistency) Meter LQ500 User Manual

Page 5

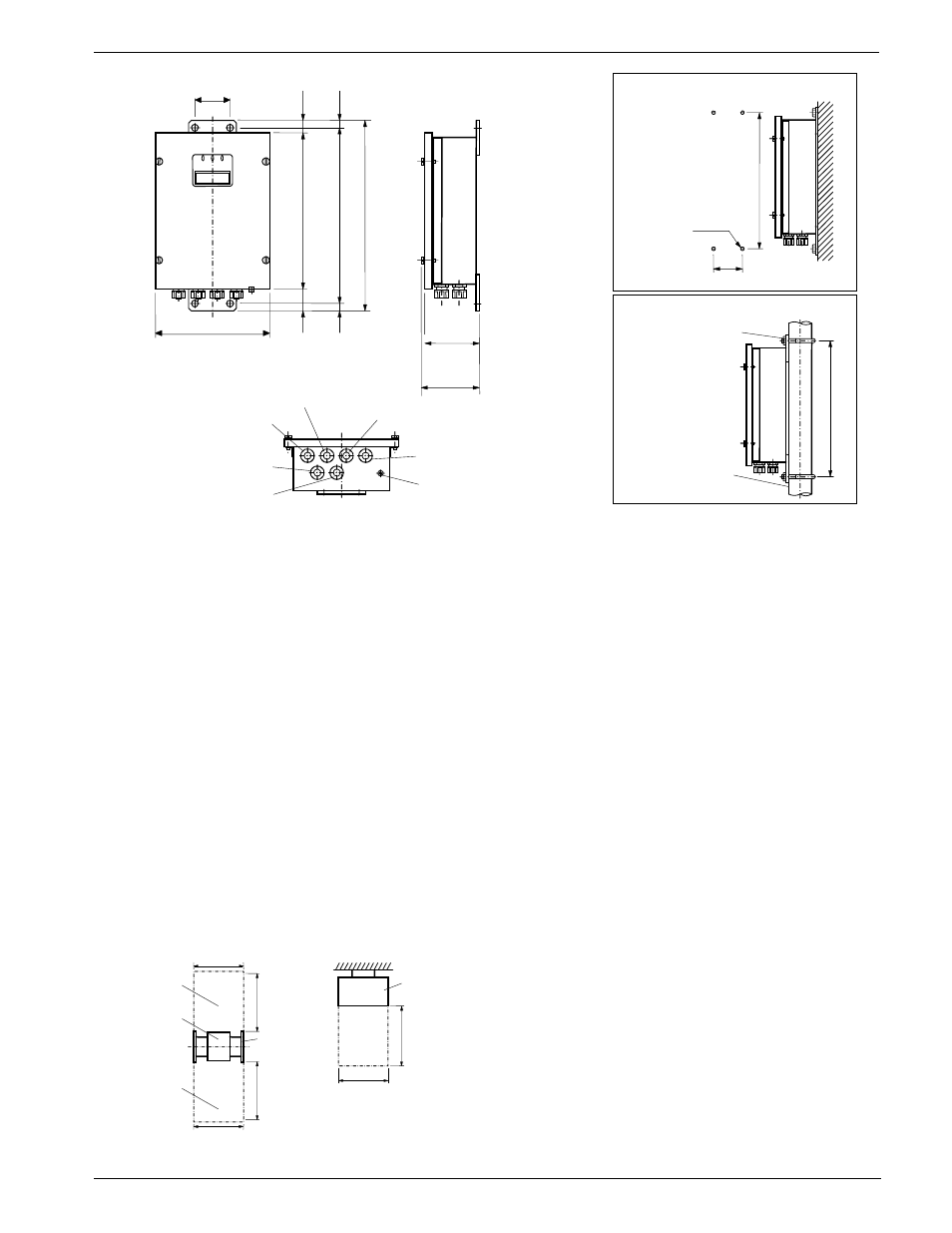

LQ500

5

110

(4.3”)

(119)

(4.7”)

Converter

communication port

Steel pipe

(50A) (2”)

360 (14

.2”

)

390 (15

.4”

)

234 (9.2”)

Contact signal I/O port (1)

Contact signal I/O port (2)

Density signal output port

Reserved

Grounding terminal

In the case of Wall mounting

In the case of 50A (2”) mounting

Steel pipe U bolt

(M10)

Converter power

supply cable port

74 (2.9”)

74 (2.9”)

320 (12

.6”

)

(25) (1.0”)

(15) (0.6”)

15

(0.6”)

45

(1.8”)

36

0 (14.2”

)

360 (14.2”

)

Unit: mm

Weight: 7kg(15 lb)

Figure 4. LQ500 Converter outline dimensions

■

Installation Precautions

(1) Install the LQ500 in an environment free from

vibration and corrosive gases and in a place

which allows easy on-site maintenance.

(2) Provide a clearance space both detector and

converter to the front, rear, and above the unit.

See Figure 5.

(3) Provide a sunshade for the detector and

converter if direct sunlight is unavoidable

when installing outdoors.

(4) The LQ500 cannot be installed in an

environment where there is a possibility that

flammable or explosive gases may leak.

(5) The LQ500 should avoid the following

environmental installations:

• Places where condensation accumulates due

to sudden temperature changes.

• Places of low or high temperature that is out

of the specification.

• Places near equipment that produces strong

electric waves or electrolytes.

• Places where flammable or explosive gas

may be generated.

500 (19.7”)

60

0 (2

3.

6”

)

Maintenance

space

Back

Front

Detector

Converter

RF part

A 500 mm (19.7”) maintenance

space is also needed above unit.

500 (19.7”)

600 (23.

6”)

60

0 (2

3.

6”

)

500 (19.7”)

Maintenance

space

Unit: mm

Figure 5. Clearance space

■

Piping Precautions

(1) A vertical installation of the LQ500 is

recommended.

Avoid installing horizontally (install LQ500

vertically) in case of following environments.

a) Places where bubbles or environments

air remain in the pipe.

b) Places where solids concentration in

the fluid is not even because solids in

the fluid stay either at the bottom or

top of the pipe due to slow fluid

velocity or other reason.

c) Pipe size is enlarged to install a larger

meter sized LQ500.

(2) Install the LQ500 in a pipeline where the

pipe is always filled with fluid and without

bubbles or entrapped air. If these conditions

are not satisfied, the measured value varies

or may give an inaccurate reading. It is

recommended that the LQ500 is installed at

the outlet instead of the suction side.

(3) Avoid places where sediment collects at the

bottom of the pipe.

(4) Avoid places where air gets into the fluid. To

avoid this problem, install the LQ500 to the

outlet of a pump, not to the suction side.

(5) When installing the detector horizontally,

install it so that the RF-part of it is oriented up

(that is, a pair of applicators stay horizontally)

to make it easier for maintenance work and to

obtain its specified performance.

(6) The LQ500 can be installed in either direction

(upstream or downstream) and without

requiring a straight pipe section. Install it in a

place allowing easy on-site maintenance.