Toshiba Density (Consistency) Meter LQ500 User Manual

Page 2

LQ500

2

range, which is the upper limit setting range.

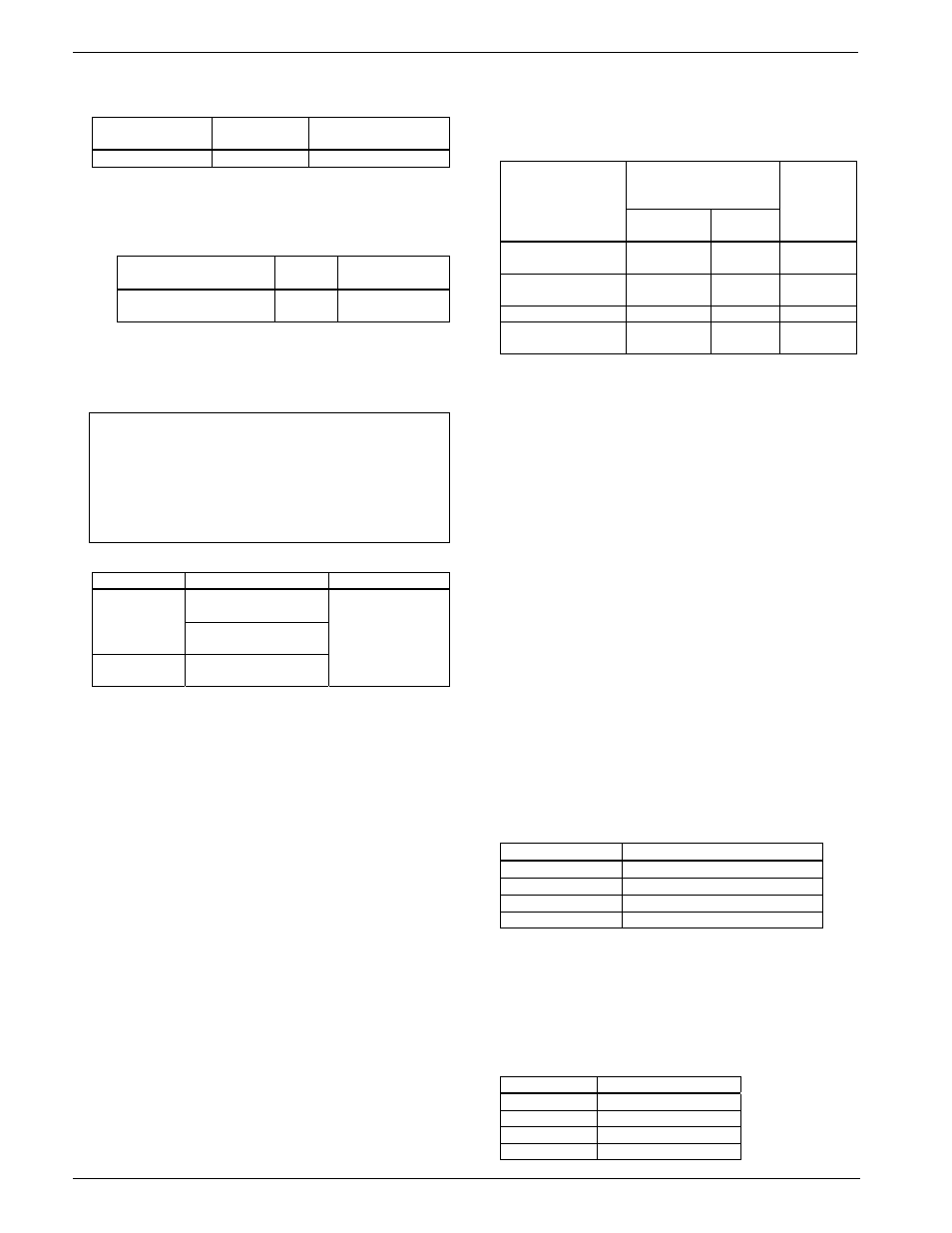

Resolution:

Meter size

50 mm (2”)

80 mm (3”)to

300 mm (12”)

Resolution 0.002%TS 0.001%TS

Note 1: Above values are the results of commuting

ability in the phase measurements of the

converter.

Note 2: Density (consistency) determination

resolution for sample reagent;

Meter size

50 mm

(2”)

80 mm (3”)to

300 mm (12”)

Density(consistency)

determination repeatability

0.1%TS 0.05%TS

* The density (consistency) determination resolution

stated above is defined due to manufacturing

limitation to make reagents with stable distribution

and a minimum difference of fluid density

(consistency).

1. Install a sample tap near the LQ500 as close

as possible to get an accurate density

(consistency) measurement using the LQ500.

2. Take several samples in rapid sequence for

more accurate density (consistency)

measurement with less human error factors.

Environmental conditions:

Items

Temperature range

Humidity range

Standard: 0 to 50 deg.C

(32 to 122 deg.F)

Detector

Option: -20 to 50 deg.C

(4 to 122 deg.F) (*1)

Converter

0 to 50 deg.C

( 32 to 122 deg.F)

5 to 85%RH

(no condensation)

*1 A rubber heater is installed at the RF part of the

detector.

Need to prepare an additional power supply either

100Vac type or 200Vac type for it by yourself.

Determine one of them at the specification code.

This option is available for detector only.

Structure: Converter;IP65,

Detector:IP67, Watertight

Note: Outdoor installation is possible. However,

provide a sunshade for the converter section if

direct sunlight is unavoidable.

Microwave power: 10 mW

Vibration resistance:

No resonance to the following levels of

vibration:

(1) No failure for 5 to 150 Hz with the following

acceleration in each device for 30 minutes in

each axis of X, Y, and Z (90 minutes);

Converter: 4.9 m/s

2

, Detector: 25m/s

2

(2) No failure for 5 to 150Hz with the following

acceleration in each device for 3 minutes in

each axis of X, Y, and Z, 10 times (90

minutes as total);

Converter: 4.9 m/s

2

, Detector: 25m/s

2

Note: Avoid using the LQ500 in an environment with

constant vibration.

Cables: See the Table 2

Table 2. Cable specifications

Cables Between detector

(RF part)and converter

(*1)

Specifications

Power supply

(24Vdc)

Communi-

cation

Power

supply

cable of

LQ500 (*2)

Cable type

CVVS-2C-2S CVVS-5C-

1.25S

CVV-3C-2S

Cross-sectional

area (*3)

2 mm

2

1.25

mm

2

2

mm

2

Number of cores

2

5

3

Cable diameter (*4)

11 to 13

mm

2

11 to 13

mm

2

11 to 13

mm

2

*1 10m (32.8 ft) length is packed as standard.

*2 Need to prepare this cable by the customer.

*3 Need to use a sheathed cable.

*4 If the diameter of the cable is smaller than the inside

diameter of the packing, enlarge the cable diameter to

the same size as the packing by wrapping around the

cable.

This dimension is coming from a diameter of the

cable gland of the LQ500.

Conformance to European Community Directives:

• EMC directive 89/336/EEC

• The low voltage 93/68/EEC

• PED 97/23/EC (Note l)

Note: See table 6 in detail.

Approved hazardous locations certification:

UL/CUL Class I, Division 2, Groups A, B, C and

D (UL/CULonly for explosion proof)

Weight: Refer to Outline Dimensions (Table 3).

Part 15 of the FCC rules: Certified.

■

Detector Specifications

Meter size: 50mm (2”), 80mm (3”), 100mm (4”),

150mm (6”), 200mm (8”), 250mm

(10”), and 300mm (12”)

Flange standard and maximum working pressure:

Flange standard

Maximum working pressure

ANSI Class 150

1 MPa (150 psi)

DIN10 and BS10

1 MPa (10 bar)

DIN 16

1.6 MPa (16 bar)

JIS 10K

1 MPa (10 kgf/cm

2

)

Note: Each product was passed a hydraulic test under

twice pressure rate for 15 minutes toward the

specification.

Fluid temperature:

0 to 100 deg.C (32 to 212 deg.F) without freezing

and bubbles conditions

Allowable fluid conductivity:

Meter size

Fluid conductivity

50 mm (2”)

20 mS/cm maximum

80 mm (3”)

16 mS/cm maximum

100 mm (4”)

15 mS/cm maximum

150 mm (6”)

10 mS/cm maximum