Toshiba Density (Consistency) Meter LQ500 User Manual

Page 3

LQ500

3

200 mm (8”)

8 mS/cm maximum

250 mm (10”)

8 mS/cm maximum

300 mm (12”)

6 mS/cm maximum

Note 1: The LQ500 can not have an accurate density

(consistency) measurement when it is over the

specification according to reduce the microwave signal.

Note 2: The LQ500 density (consistency) measurement

for application where liquids containing highly

conductive particles such as active carbon and

metal particles may be affected. Consult

Toshiba for detail when the measuring liquid

contains such particles.

Wetting materials:

Name Materials

(*1)

Main pipe

SCS14A cast (equivalent to

316 SS) (standard) (*2, *3)

Temperature detector sheath

316 stainless steel (*4)

Applicator window

Polysulfone (*4)

Applicator window sealant

Fluoric rubber

*1 Avoid using the LQ500 for applications where

harmful liquids that cause corrosion, deterioration, or

changes in quantity for the wetting materials are used.

Make sure all materials at these wetting parts that are

suitable for your CIP or not before cleaning.

*2 The smoothness inside the pipe on this material is;

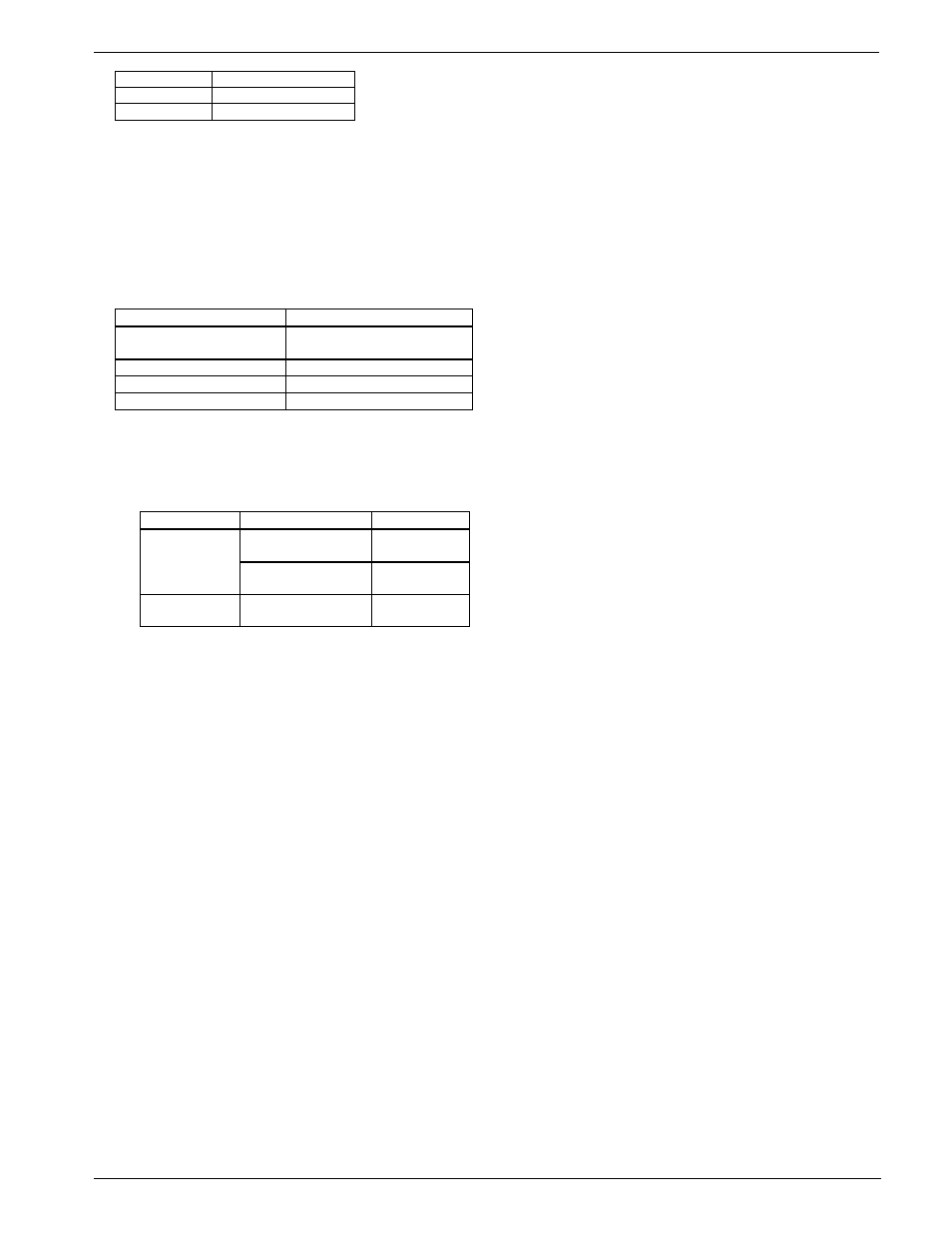

Type Meter

size

Smoothness

50 to 200 mm

(1/2” to 8”)

No buffing

Standard type

250 & 300 mm

(10” & 12”)

Buffing # 150

Option type

50 to 300 mm

(1/2” to 12”)

Buffing # 150

*3 State the wetted materials when you choose these

options.

*4 The materials of them are changed for abrasive

applications.

Need to choose the specification code for this

application.

Applicator:

Serves as an antenna to send

and receive

microwave signals, one set provided.

Temperature detector: RTD (Pt100)

Fitting:

Direct fitting to vertical or horizontal

piping. (Refer to the section of Piping

Precautions.)

■

Converter Specifications

Output signals

• Density (consistency) measurement output:

4-20mAdc (load resistance 750 ohm maximum,

isolated output.)

• Density (consistency) fault or Maintenance

signal: 125Vac, 0.1A (resistive load) solid

state contact; opens when an error occurs in the

converter or when the LQ500 is in the setting

change mode, otherwise the contact remains

closed.

Communication signal:

Digital signal is superimposed on 4-20mAdc

current signal (conforming to HART protocol(*1)).

Load resistance:240 to 750 ohm

Load capacity:0.25μF maximum

*1 HART (Highway Addressable Remote

Transducer) protocol is a communications

protocol for industrial sensors recommended

by HCF (HART Communication Foundation).

Note: The optional AF900 hand-held terminal can be

used to operate the LQ500 from remote places

by connecting the AF900’s probe lead between

the LQ500’s 4-20 mA dc output signal lines.

Input signals

• External synchronized input signal:

In order to avoid problems of density

(consistency) measurement such as

inhomogeneous condition caused by

discontinuous process operation and empty pipe

condition caused by stopping process operation.

One dry “make” contact;

Contact capacity of 24Vdc with 0.1 to 2.0A is

required.

This contact signal can be used to start or stop

density (consistency) measurement in

synchronization with an external contact, such

as the contacts on a pump.

The measurement starts or stops as follows:

Contact closed: Starts density (consistency)

measurement.

Contact open: Stops density (consistency)

measurement.

• Density multiplier switching signal:

In order to achieve selecting up to 4 kinds of

liquid concentration measurement independently

as maximum.

Two voltage signals described below are required:

Input voltage: H level: 20 to 30 Vdc

L level: 2 Vdc or less

Input resistance: Approx. 3k ohm

• Conductivity correction signal:

Need to prepare an additional conductivity meter

when using this function. Install in where is able

to have a stable and accurate measurement.

Input signal: 4 to 20mAdc

Conductivity range: 0 to 10mS/cm

Update period for density (consistency)

measurement output and display:

Approx. 1 second

Functions by software as standard:

• Data saving function:

In order to save measurement data into the

memory of converter temporary.

The oldest data is overwritten.

Data storage points: 256 points maximum.

Period: 1 to 1,800 minutes (1 minute each).

ex 1: The data is saved for approx. latest 4.26

hours when programming every minute.

ex 2: The data is saved for approx. latest 21.3