Troy-Bilt TB310QS User Manual

Page 6

6

MAINTENANCE AND REPAIR INSTRUCTIONS

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in the table. These procedures

should also be a part of any seasonal tune-up.

NOTE:

Some maintenance procedures may require special tools or skills. If you are unsure about

these procedures take your unit to any non-road engine repair establishment, individual or

authorized service dealer.

NOTE:

Maintenance, replacement, or repair of the emission control devices and system may be

performed by any non-road engine repair establishment, individual or authorized service dealer.

In order to assure peak performance of your engine, inspection of the engine exhaust port may be necessary

after 50 hours of operation. If you notice lost RPM, poor performance or general lack of acceleration, this

service may be required. If you feel your engine is in need of this inspection, refer service to any non-road

engine repair establishment, individual or authorized service dealer for repair. DO NOT attempt to perform this

process yourself as engine damage may result from contaminants involved in the cleaning process for the port.

WARNING:

To prevent serious injury, never perform maintenance or repairs with unit

running. Always service and repair a cool unit. Disconnect the spark plug wire to ensure

that the unit cannot start.

FREQUENCY

MAINTENANCE REQUIRED

SEE

Before starting engine

Fill fuel tank with fresh fuel

Page 4

Every 10 hours

Clean and re-oil air filter

Page 6

Every 25 hours

Check and clean spark arrestor

Check spark plug condition and gap

Page 6

Page 6

Every 50 hours

Inspect exhaust port and spark arrestor screen for clogging

or obstruction to assure maximum performance levels

Page 6

AIR FILTER MAINTENANCE

Removing the Air Filter/Muffler Cover

1.

Place the choke lever in Position 2.

NOTE:

The choke lever must be in Position 2 (Fig. 21) to

remove the air filter/muffler cover.

2.

Remove the four (4) screws securing the air filter/muffler

cover (Fig. 21). Use a T20 Torx bit screwdriver.

2.

Pull the cover from the engine. Do not force.

Cleaning the Air Filter

Clean and re-oil the air filter every 10 hours of operation. It is an important

item to maintain. Failure to maintain your air filter properly can result in

poor performance or can cause permanent damage to your engine.

1.

Remove air filter/muffler cover. Refer to Removing the Air

Filter/Muffler Cover.

2.

Turn cover over and look inside to locate the air filter.

Remove the air filter from inside the air filter/muffler cover

(Fig. 22).

3.

Wash the filter in detergent and water (Fig. 23). Rinse the filter

thoroughly. Squeeze out excess water. Allow it to dry completely.

4.

Apply enough clean SAE 30 oil to lightly coat the filter (Fig. 24).

5.

Squeeze the filter to spread and remove excess oil (Fig. 25).

6.

Replace the air filter inside the air filter/muffler cover (Fig. 22).

NOTE:

Operating the unit without the air filter and air

filter/muffler cover assembly will VOID the warranty.

Reinstalling the Air Filter/Muffler Cover

1.

Place the air filter/muffler cover over the back of the

carburetor and muffler. Align the screw holes.

NOTE:

The choke lever must be in Position 2 (Fig. 21) to

install the air filter/muffler cover.

2.

Insert the four (4) screws into the holes in the air

filter/muffler cover (Fig. 21) and tighten.

Do not over tighten.

SPARK ARRESTOR MAINTENANCE

NOTE:

The exhaust can only flow in one direction: AWAY

from the engine. Pay close attention when

disassembling the muffler so you can put it back

together correctly. Failure to do so will damage the

unit and may cause serious personal injury.

1.

Remove air filter/muffler cover. Refer to Removing the Air

Filter/Muffler Cover.

2.

Locate the muffler, but do not remove it. Find the two (2) screws

on the bottom of the muffler (Fig. 26). These two screws hold the

Spark Arrestor Hood Assembly and the spark arrestor screen to

the bottom of the muffler. Remove the two (2) screws using either

a torx #20 or flat blade screwdriver.

3.

Using a small flat blade screwdriver, carefully pry up the spark

arrestor screen from the recessed hole, taking care to notice that

the “raised” part of the spark arrestor screen is inside the recessed

hole. Remove the spark arrestor screen from the muffler.

4.

Clean the spark arrestor screen with a wire brush. Replace

it if it is damaged, or if you are unable to clean it thoroughly.

5.

Reinstall the spark arrestor screen by putting the “raised”

portion of the screen inside the recessed hole of the muffler.

Make sure that the spark arrestor screen fits flat against the

muffler.

6.

Place the spark arrestor plate on top of the spark arrestor

with the “raised” side up and the opening facing towards the engine (Fig. 26).

7.

Place the spark arrestor hood on top of the spark arrestor plate with the “raised” side up and the opening

facing AWAY from the engine (Fig. 26). Verify that the exhaust will be directed AWAY from the engine.

8.

Replace the two screws you removed in Step 2 and tighten them securely.

9.

Reinstall the air filter/muffler cover.

MAINTENANCE AND REPAIR INSTRUCTIONS

CARBURETOR ADJUSTMENT

The idle speed of the engine is adjustable through the air filter/muffler cover (Fig. 27).

NOTE:

Careless adjustments can seriously damage your unit. An authorized service dealer should

make carburetor adjustments.

Check Fuel Mixture

Old and/or improperly mixed fuel is usually the reason for improper unit performance. Drain and refill the

tank with fresh, properly-mixed fuel prior to making any adjustments. Refer to Oil and Fuel Information.

Clean Air Filter

The condition of the air filter is important to the operation of the unit. A dirty air filter will restrict air flow

and change the air/fuel mixture. This is often mistaken for an out of adjustment carburetor. Check the

condition of the air filter before adjusting the idle speed screw. Refer to Air Filter Maintenance.

Adjust Idle Speed Screw

If after checking the fuel mixture and cleaning the air filter the engine still will not idle, adjust the idle speed

adjuster as follows.

1.

Start the engine and let it run at the fast position for a minute to warm up.

2.

Set the blower/vacuum mode Quickshift

®

lever to the up position (Blower Mode). Refer to Operating as a Blower.

NOTE:

Setting the lever to the blower mode prevents the vacuum bag from filling up while starting or

running the unit.

3.

Move the throttle control and let the engine idle. If the engine stops, insert a small phillips

screwdriver into the hole in the air filter/muffler cover (Fig. 27). Turn the idle speed adjuster in,

clockwise, 1/8 of a turn at a time (as needed) until the engine idles smoothly.

4.

If the unit appears to be idling too fast, turn the idle speed adjuster counterclockwise 1/8 of a turn

at a time (as needed), to reduce idle speed.

Checking the fuel mixture, cleaning the air filter, and adjusting the idle speed should solve most engine problems.

If not and all of the following are true:

•

the engine will not idle

•

the engine hesitates or stalls on acceleration

•

there is a loss of engine power

Have the carburetor adjusted by an authorized service dealer.

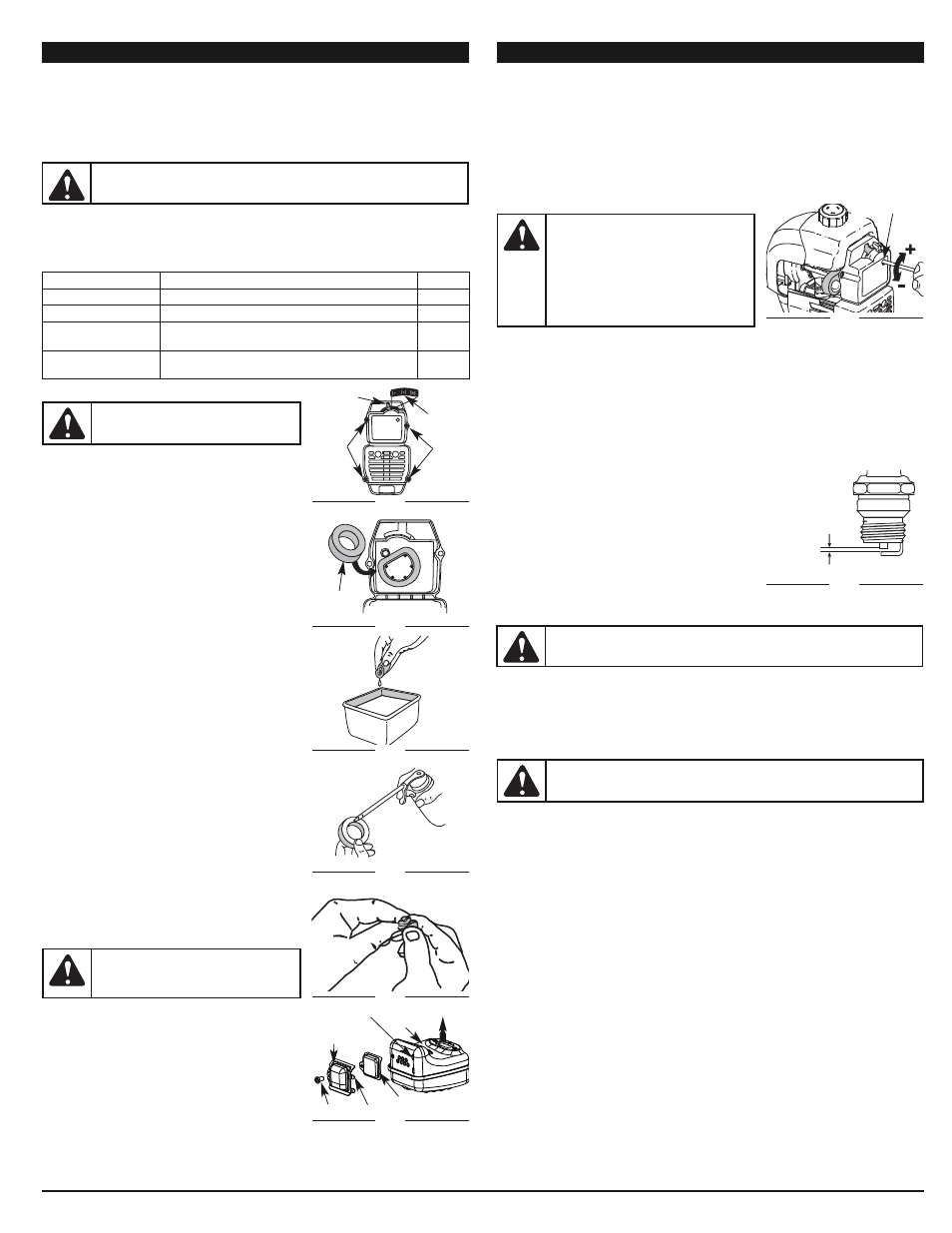

REPLACING THE SPARK PLUG

Use spark plug P/N 791-610311B, or equivalent. The correct air

gap is 0.025 inch (0.635 mm). Remove the plug after every 25

hours of operation and check its condition.

1.

Stop the engine and allow it to cool. Grasp the plug wire

firmly and pull it from the spark plug.

2.

Clean around the spark plug. Remove the spark plug from the cylinder head by turning a 5/8-inch

socket counterclockwise.

3.

Replace a cracked, fouled or dirty spark plug. Set the air gap at 0.025 inch (0.635 mm) using a

feeler gauge (Fig. 28).

4.

Install a correctly-gapped spark plug in the cylinder head. Tighten by turning the 5/8-inch socket

clockwise until snug.

If using a torque wrench torque to: 110-120 in.•lb. (12.3-13.5 N•m)

Do not over tighten.

CLEANING THE UNIT

Use a small brush to clean off the outside of the unit. Do not use strong detergents. Household cleaners

that contain aromatic oils such as pine and lemon, and solvents such as kerosene, can damage plastic

housing or handle. Wipe off any moisture with a soft cloth.

CLEANING THE VACUUM BAG

1.

Empty the bag after each use to avoid deterioration and obstructing air flow, which will reduce the

performance of the vacuum.

2.

Wearing eye protection and a dust mask, clean the bag as needed. Turn the bag inside out after

initial emptying and vigorously shake out dust and debris.

3.

Wash the bag once a year or more often if needed:

a. Remove the vacuum bag.

b. Turn bag inside out.

c. Hang it up.

d. Hose it down thoroughly.

e. Hang to dry.

f.

Turn bag right-side out and reinstall.

STORAGE

•

Never store a fueled unit where fumes may reach an open flame or spark.

•

Allow the engine to cool before storing.

•

Store the unit locked up to prevent unauthorized use or damage.

•

Store the unit in a dry, well-ventilated area.

•

Store the unit out of the reach of children.

Blue Choke

Lever

Screws

Position 2

Fig. 21

Screws

Air Filter

Inside Muffler Cover

Fig. 22

WARNING:

If the spark arrestor hood and

spark arrestor screen are not tightened securely,

they could fall off causing damage to the unit

and possible serious personal injury.

WARNING:

Do not sand blast, scrape or clean electrodes. Grit in the engine could

damage the cylinder.

WARNING:

To avoid serious personal injury, always turn your trimmer off and allow it to

cool before you clean or service it.

Fig. 25

Slots

Spark

Arrestor

Hood

Screw

Fig. 26

Tabs

Spark Arrestor

Screen

Engine

Muffler

Idle Speed Screw

Fig. 27

Fig. 23

Fig. 24

0.025 in.

(0.635 mm)

Fig. 28

WARNING:

This unit will need to be running during

idle speed adjustment. Wear protective clothing and

observe all safety instructions to prevent serious

personal injury.

Also, DO NOT set unit on any surface except a clean,

hard area while starting or performing any adjustments.

Debris such as gravel, sand, dust, grass, etc. could be

picked up by the air intake and thrown out by the

discharge opening, damaging unit, property, or causing

serious injury to bystanders or operator.

WARNING:

To avoid serious personal injury,

always turn your unit off and allow it to cool

before you clean or service it.