Troy-Bilt TB310QS User Manual

Page 4

ASSEMBLY INSTRUCTIONS

OIL AND FUEL INFORMATION

1.

Mix gas with oil. Fill fuel tank with fuel/oil mixture.

See Oil and Fuel Mixing Instructions.

NOTE:

The throttle control will remain in the position

it’s placed until moved. Fast position is to the

right. Also, there is no need to turn the unit on.

The On/Off Stop Control is in the ON (I) position at all times.

STARTING INSTRUCTIONS

WARNING:

Operate this unit only in a well-ventilated outdoor area. Carbon monoxide

exhaust fumes can be lethal in a confined area.

WARNING:

Avoid accidental starting. Make sure you are in the starting position when

pulling the starter rope (Fig. 11). To avoid serious injury, the operator and unit must be

in a stable position while starting.

Throttle Control

Fig. 9

Slow

On/ Off Stop

Control

4

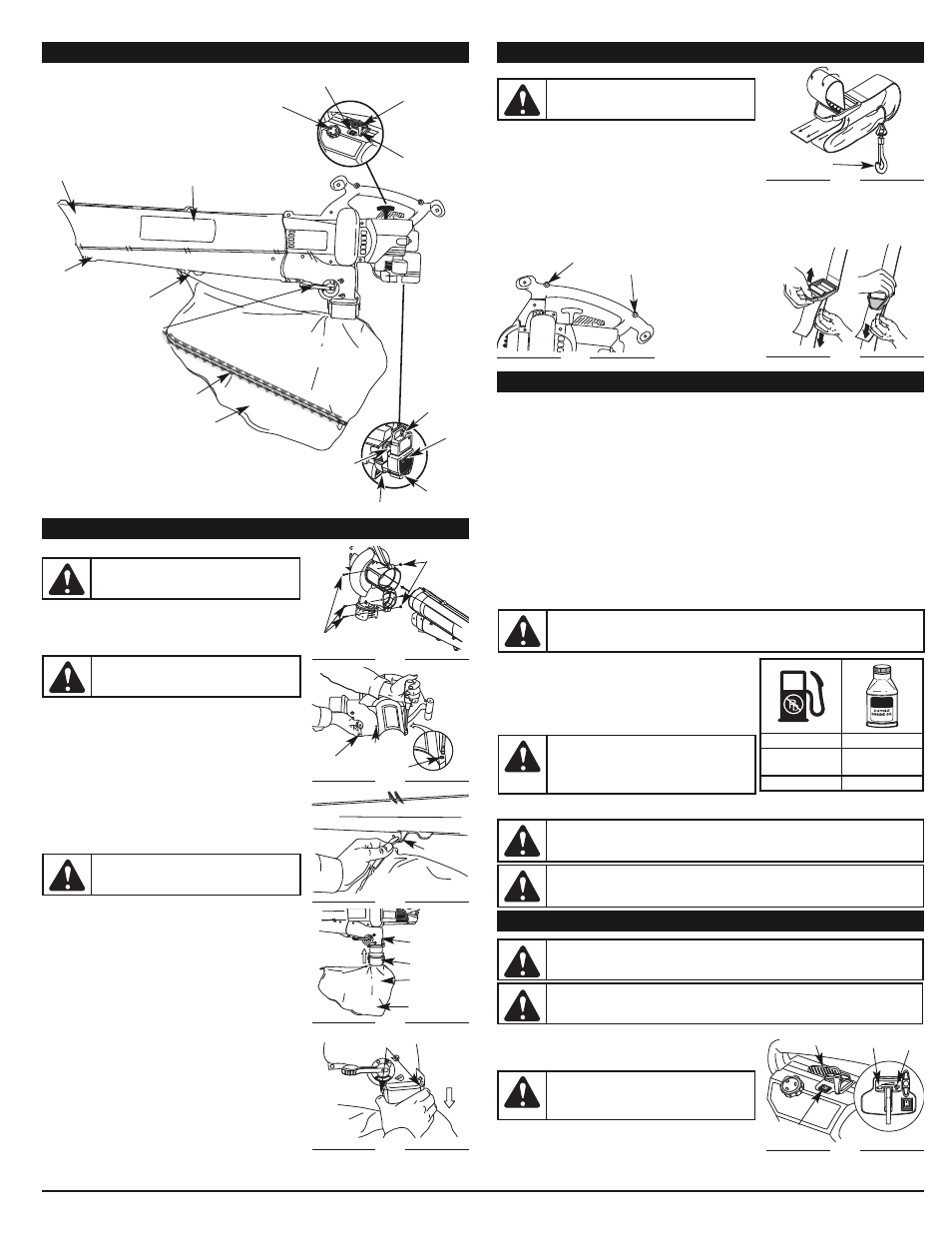

KNOW YOUR UNIT

Blower/Vacuum Mode

Quickshift™ Lever

Fuel Cap

Throttle

Control

Blower Outlet

Vacuum Bag

Zipper

Blower/ Vacuum

Tube

Primer Bulb

Blue Choke

Lever

Spark Plug

On/Off Stop

Control

Vacuum Bag

Hook

Starter Rope

Grip

Vacuum Bag

Muffler

Air Filter

Cover

APPLICATION

As a blower:

•

Cleaning yards, garages, driveways, porches,

patios, around walls, fences and more

As a vacuum:

•

Picking up leaves and other light debris

Vacuum Inlet

ATTACHING AND REMOVING THE BLOWER/VACUUM TUBE

Attaching

NOTE:

The blower/vacuum tube comes unassembled on this

unit. Installation is required to provide safe and easy

use for the operator.

1.

Remove the screws and nuts provided from the hardware pack.

2.

Insert the blower/vacuum tube all the way into the opening

on the motor housing until the holes in the tabs on the

blower/vacuum tube align with the screw holes in the

housing (Fig. 1).

3.

Insert the 2 (two) 8-32 x 3/4” slotted T20 Torx screws into

the right side of the motor housing and the 2 (two) nuts into

the left side of the motor housing (Fig. 1).

4.

Tighten the screws firmly. Do not over-tighten.

5.

Install the 2 (two) remaining self-tapping 8-16 x 3/4” slotted

T20 Torx screws into the holes on either side of the housing

(Fig. 1). Tighten until snug, do not over-tighten.

Removing

NOTE:

It may be necessary to remove the blower/vacuum

tube to clear a blocked tube or impeller.

1.

Remove the 2 (two) self-tapping screws from either side of

the housing.

2.

Remove the 2 (two) screws and nuts holding the

blower/vacuum tube on the housing (Fig. 2).

NOTE:

Keep the hardware in a safe place for future use.

3.

Remove the blower/vacuum tube from the motor housing.

4.

Replace blower/vacuum tube before use.

ATTACHING AND REMOVING THE VACUUM BAG

Attaching

1.

Attach the vacuum bag to the vacuum bag hook on the

blower/vacuum tube (Fig. 3).

2.

Slide the vacuum bag tube over the debris exhaust tube on

the housing. Push the tube until the latching tabs on both

sides click into place, securing the bag on the unit (Fig. 4).

Removing

1.

Press the latching tabs on both sides of the vacuum bag

tube and pull the vacuum bag down from the unit (Fig. 5).

2.

Detach the vacuum bag from the vacuum bag hook.

Fig. 2

Screw

Fig. 1

WARNING:

To avoid serious personal injury,

the blower/vacuum tube and vacuum bag must

be used when operating this unit.

WARNING:

To prevent serious personal injury,

stop the engine and allow the impeller to stop

before attaching or removing tubes.

WARNING:

To prevent serious personal injury,

stop the engine and allow the impeller to stop

before attaching or removing tubes.

Fig. 4

Vacuum

Bag Hook

Fig. 3

ASSEMBLY INSTRUCTIONS

INSTALLING THE SHOULDER HARNESS (OPTIONAL)

The shoulder strap is an optional accessory.

1.

Push the strap through the center of the buckle.

2.

Pull the strap over the cross bar and down through the slot

in the buckle (Fig. 6).

3.

Snap the clip on to the support fittings on the front or back

of the handle. Clip to the front portion of the handle when

using the unit as a blower, and clip to the back portion of the handle when using the unit as a

vacuum (Fig. 7).

4.

While standing in the operating position adjust length to fit the operator’s size. Pull tab to lengthen,

pull strap to shorten (Fig 8).

WARNING:

To prevent serious personal injury,

stop the engine and allow the impeller to stop

before attaching or removing tubes.

Clip

Fig. 6

Fig. 8

Attach Here

for Blower

Fig. 7

OIL AND FUEL MIXING INSTRUCTIONS

Old and/or improperly mixed fuel are the main reasons for the unit not running properly. Be sure to use

fresh, clean unleaded fuel. Follow the instructions carefully for the proper fuel/oil mixture.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as ethanol, methanol, or MTBE (ether).

Alcohol-blended fuel absorbs water. As little as 1% water in the fuel can make fuel and oil separate. It

forms acids when stored. When using alcohol-blended fuel, use fresh fuel (less than 60 days old).

Using Blended Fuels

If you choose to use a blended fuel, or its use is unavoidable, follow recommended precautions:

•

Always use the fresh fuel mix explained in your operator's manual

•

Always agitate the fuel mix before fueling the unit

•

Drain the tank and run the engine dry before storing the unit

Using Fuel Additives

The bottle of 2-cycle oil that came with your unit contains a fuel additive which will help inhibit corrosion

and minimize the formation of gum deposits. It is recommended that you use our 2-cycle oil with this unit.

If unavailable, use a good 2-cycle oil de-signed for air-cooled engines along with a fuel additive, such as

STA-BIL® Gas Stabilizer or an equivalent. Add 0.8 oz. (23 ml.) of fuel additive per gallon of fuel according

to the instructions on the container. NEVER add fuel additives directly to the unit's fuel tank.

Thoroughly mix the proper ratio of 2-cycle engine oil with

unleaded gasoline in a separate fuel can. Use a 40:1 fuel/oil

ratio. Do not mix them directly in the engine fuel tank. See the

table below for specific gas and oil mixing ratios.

NOTE:

One gallon (3.8 liters) of unleaded gasoline mixed

with one 3.2 oz. (95 ml.) bottle of 2-cycle oil makes

a 40:1 fuel/oil ratio.

NOTE:

Dispose of the old fuel/oil mix in accordance to

Federal, State and Local regulations.

MIXING RATIO - 40:1

UNLEADED GAS

2 CYCLE OIL

1 GALLON US

(3.8 LITERS)

3.2 FL. OZ.

(95 ml)

1 LITER

25 ml

CAUTION:

For proper engine operation and maximum reliability, pay strict attention to

the oil and fuel mixing instructions on the 2-cycle oil container. Using improperly mixed

fuel can severely damage the engine.

WARNING:

Gasoline is extremely flammable.

Ignited vapors may explode. Always stop the engine

and allow it to cool before filling the fuel tank. Do not

smoke while filling the tank. Keep sparks and open

flames at a distance from the area.

WARNING:

Remove fuel cap slowly to avoid injury from fuel spray. Never operate the

unit without the fuel cap securely in place.

WARNING:

Add fuel in a clean, well ventilated outdoor area. Wipe up any spilled fuel

immediately. Avoid creating a source of ignition for spilt fuel. Do not start the engine until

fuel vapors dissipate.

WARNING:

To avoid serious personal injury,

always remove the vacuum bag prior to refueling

the unit. The bag may become a fire hazard

when saturated with fuel.

STARTING/STOPPING INSTRUCTIONS

Fig. 5

Engine

Housing

Nut

Blower/ Vacuum

Tube

Screw &

Nut

Screw &

Nut

Screw

Debris Exhaust

Tube

Vacuum Bag

Tube

Vacuum Bag

Zipper

Latching Tabs

PRESS IN

PRESS IN

Attach Here

for Vacuum

Fast