P503dl control board led status – Toshiba P503DL User Manual

Page 33

33

The lamp used is UHP 100/120W, driven by the ballast, this lamp/ballast combination is made by

Philips enables to select lamp power for 100W or 120W by mechanical slide switch.

Do not replace the lamp with other model, a reflector which focuses the lamp b eam is designed for

DLP use, with light tunnel application. Different lamp may not have right specification or lamp life

may be much different. The lamp for previous model, P500DL, is different from the P503DL lamp.

To avoid such confusion, the lamp connector has different shape so that other lamp will not fit.

3.

Power Supply PCB

The power supply consists of two sections, Power Factor Control and DC-DC conversion.

Incoming AC is rectified and supplied to the PFC converter, where the voltage and current phases are

matched, thus resulting power factor becomes 1.

The output of the PFC circuit is 380V DC and this is supplied to the main DC-DC converters and also

the Lamp Ballast.

The outputs of the main DC -DC converter are +12V, +6V and +4.5V.

Also, +12V which is connected to the fans and +5V for micro processor are separately prepared.

4.

Lamp Ballast PCB

The Philips® 100/120W UHP lamp is driven by Philips ballast, power supply. The input voltage is

380V DC and high voltage trigger which is about 20kV pulse to ignite while lamp start period and

lamp supply voltage is given to continue to its discharge by about AC50V, plus non-flicker pulse drive

voltage is superimposed from lamp ballast output.

5.

RS232C Control PCB

RS232C control signal or/and remote control from optional CT90000 are accepted, if both are

connected CT90000 has priority over RS232C communication line.

RS232C parallel cables need to use.

6.

Video PCB (option)

Accepts PAL/NTSC/SECAM composite video signal and has a buffered output for loop-through.

Normally in case of PC picture, DVI internal link would be used for not so much active movement

pictures but in case of video picture, sometimes, DVI link may contain some picture frames of delay

occurred by each cubes so that images of all the cubes ma y not match but later the connection,

more movement delays may result.

In such occasion, Video output to next video input, video loop through may results better picture

by less delay composed.

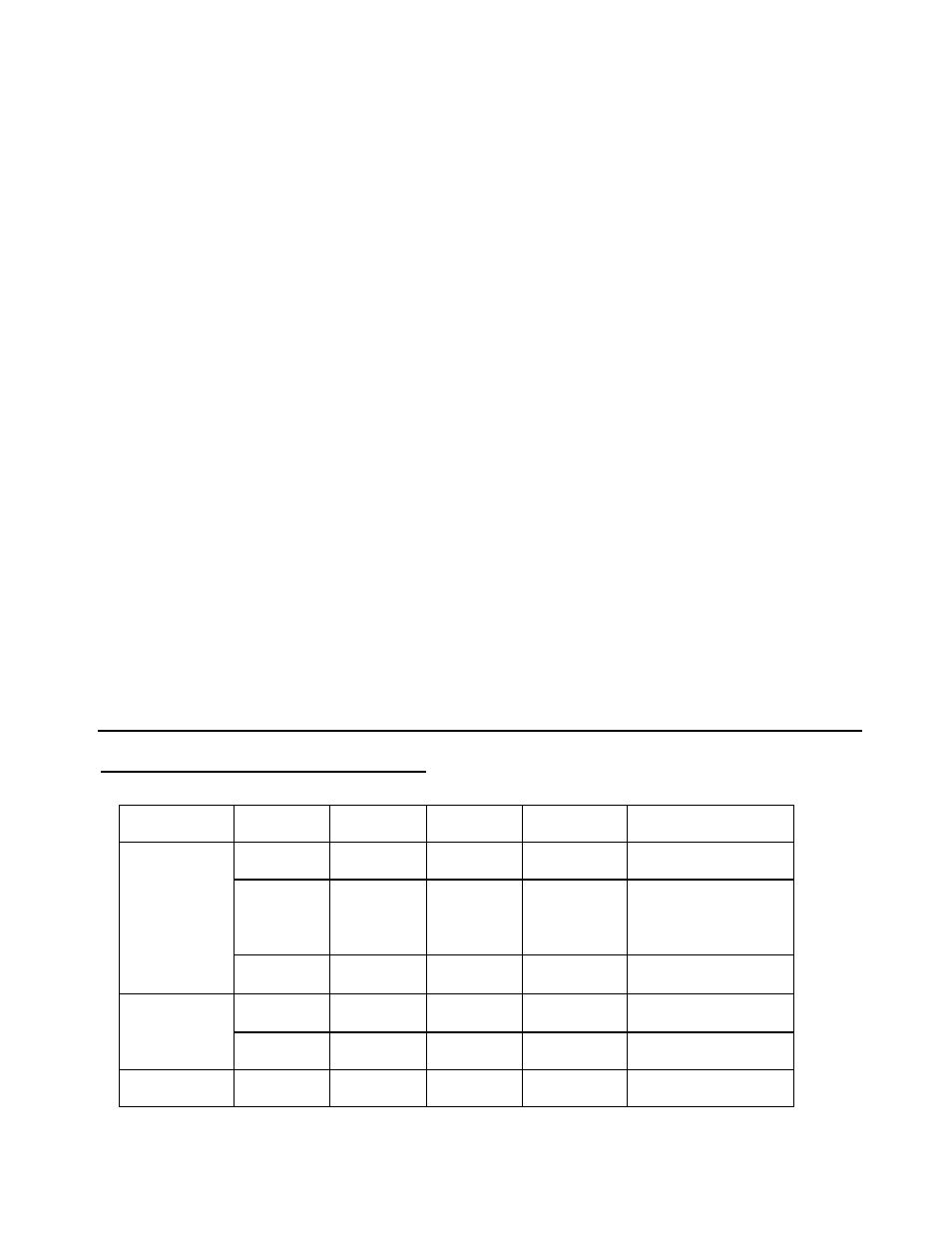

Appendix-1

P503DL control board LED status

POWER

FAN

LAMP

Blink time

OFF

OFF

OFF

ON (red)

OFF

OFF

ON (green)

ON (green)

OFF

Before Lamp lights

POWER OFF

STANBY

Preparation

POWER ON

ON (green)

ON (green)

ON (green)

After Lamp lights up

ON (green)

ON (green)

ON (green)

Normal

FAN STOP

ON (green)

Blink

(green)

OFF

0.2 SEC

Lamp will shutdown

LAMP cannot

light

ON (green)

ON (green)

OFF