Quincy Compressor 50093-103 User Manual

Page 68

62

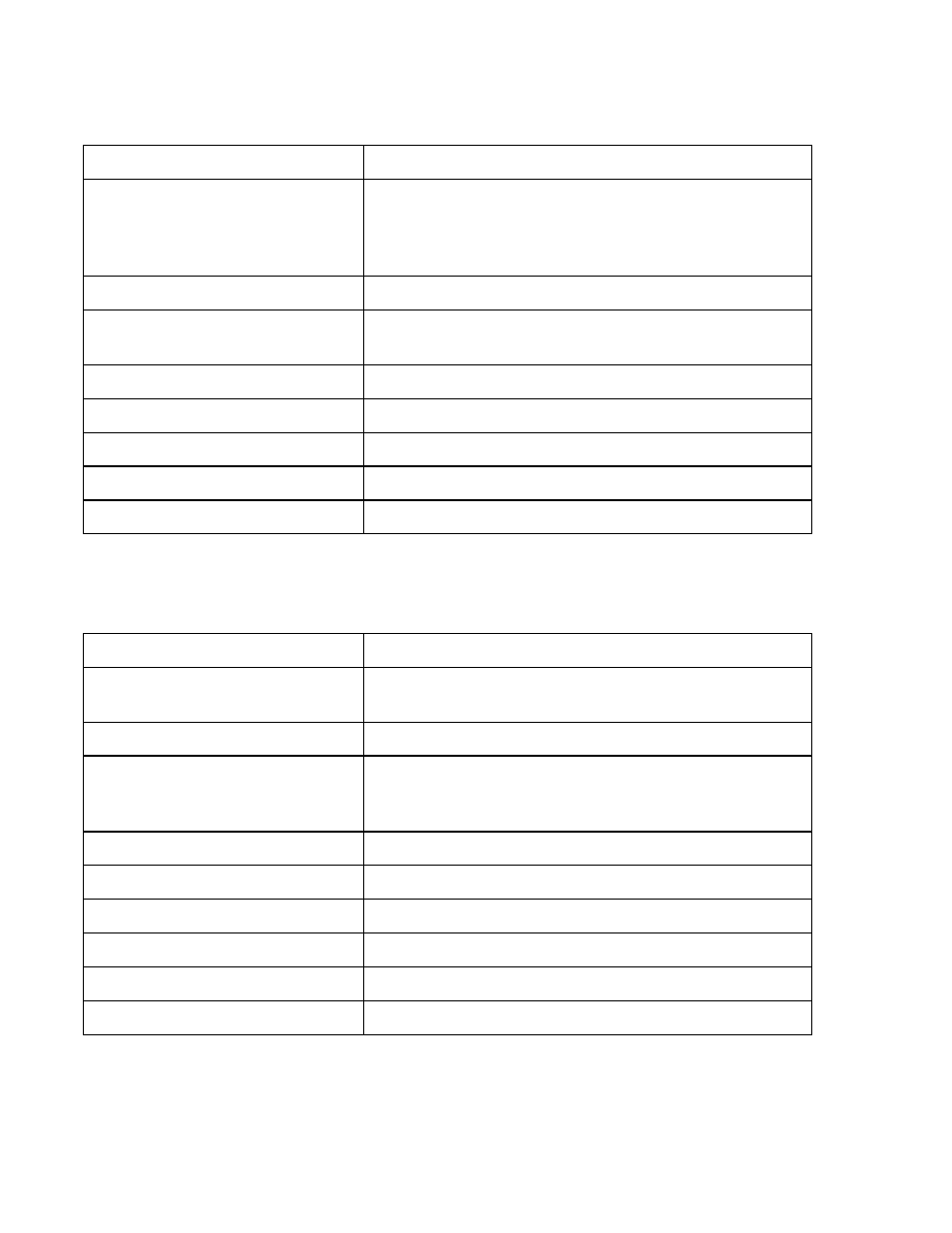

UNIT OPERATING WITH HIGH DISCHARGE TEMPERATURES

PROBABLE CAUSE

CORRECTION

Clogged fluid cooler

Check fluid cooler for varnishing and rust deposits. If this

condition exists, clean cooler thoroughly in accordance with

recommended procedures of the heat exchanger

manufacturer.

Excessive ambient temperatures

Maximum ambient for proper operation is 110°F.

Incorrect fan rotation

Correct rotation with the fan pushing the air up through the

coolers.

Improper fluid

Use recommended fluids only - see fluids section.

Clogged air filter

Clean and replace as necessary.

Faulty thermal valve

Repair or replace as necessary.

Faulty gauges

Check and replace.

Airend failure

Contact a Quincy authorized distributor.

EXCESSIVE FLUID CONSUMPTION

PROBABLE CAUSE

CORRECTION

Too high fluid level in the receiver

Bring fluid level down to the recommended level by

draining the receiver. Use the fluid level gauge as a guide.

Plugged scavenger line

Clean scavenger line orifice and tube.

High fluid injection temperature

Correct the situation in accordance with the instructions in

"High Discharge Air Temperature and/or High Fluid

Temperature" section of this guide.

Too high inlet pressure

Operate continuously at 10" HgV and above.

Faulty or damaged separator

Change air/fluid separator.

Leak in fluid lines

Check for leaks and repair.

Seal failure, leaks

Replace seat assembly.

Incorrect fluid

Use recommended fluids only - see fluids section.

Rapid cycling

Consult factory.