Air distribution guide – Rinnai 37AHB SERIES User Manual

Page 29

Rinnai Corporation Hydronic Furnace (37AHB) Manual

29

Air Distribution Guide

Hydronic Furnace, He/ She should adhere to the

following basic rules whenever possible.

1. Duct joints shall be, as a rule, sealed to prevent

leakage of air which may cause objectionable sound.

2. Round ducts are favored to rectangular (on the

supply side) as they offer greater rigidity and higher

efficiency.

3. Fitting selection and placement should also be

carefully studied as the correct fitting and its location

will avoid excessive pressure drops and likely noise

problems.

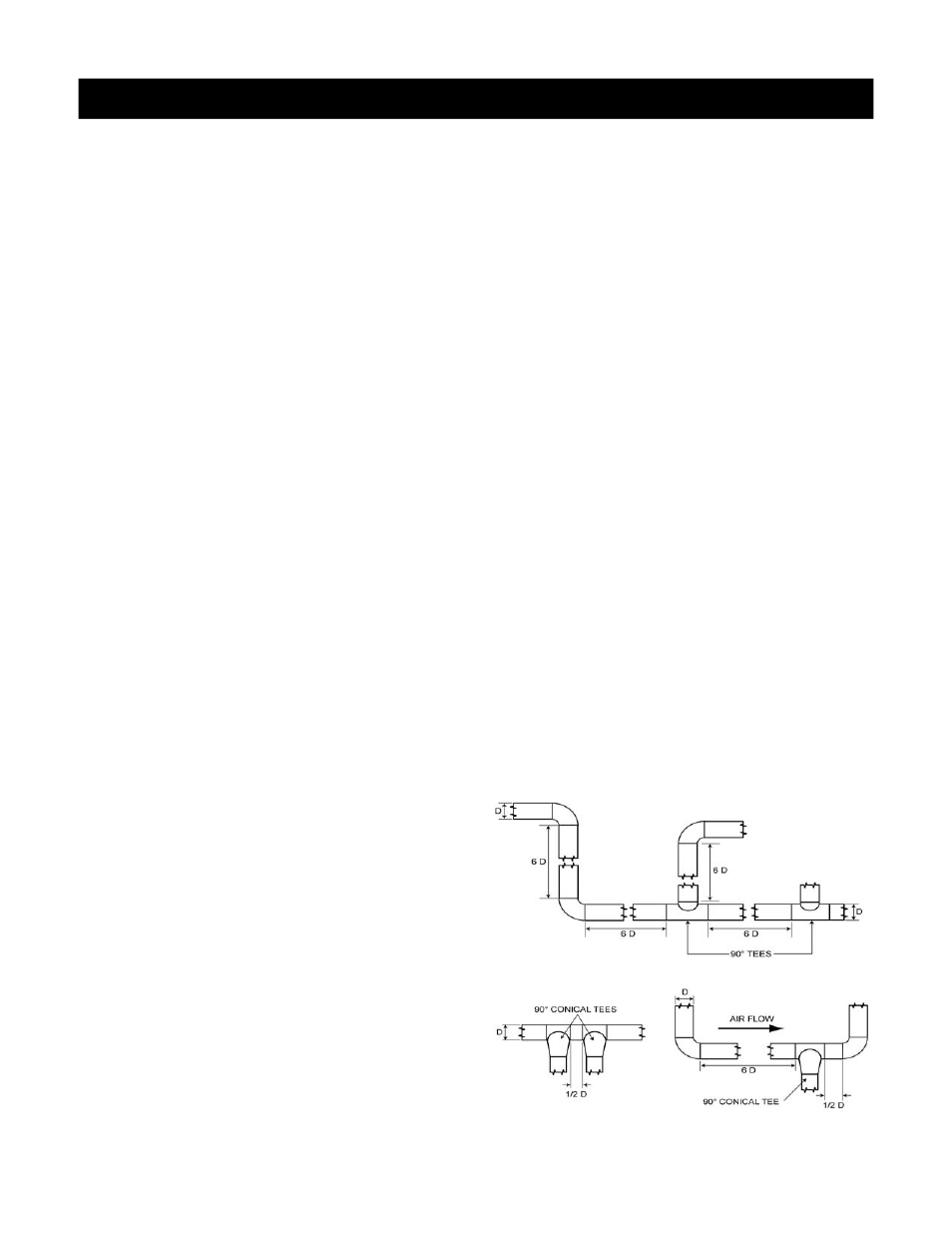

4. Figures 25 and 26 illustrate the critical distance as

regards high velocity ducting system design.

Additionally, when laying out the header section for a

typical high velocity system, the following factor must

be considered:

Unless space conditions dictate otherwise, the

take-off from the header should be made using a

90

o

tee or 90

o

conical tee rather than a 45

o

tee.

By using 90

o

fittings, the pressure drop to the

branch throughout the system is more uniform. In

addition, two fittings are normally required when a

45

o

tee is used and only one when a 90

o

fitting is

used, resulting in lower first cost.

Practically speaking, the design of a high velocity

system is basically the same as a low velocity duct

system. If concerns about noise were not a factor,

duct runs could be sized according to the smallest

permissible duct diameter which would be governed

only by the available external static pressure. In

opposition, since noise reduction is paramount in

residential designs, the designer must take special

care to ensure that all duct sizes are compatible with

velocity limits that are associated with both the

discharge and return sides of the planned system.

To all intents and purposes, duct sizing calculations

are based on fan performance and air side accessory

pressure drop data that are provided by original

equipment manufacturers. The importance of

ensuring that the total pressure drop of the longest

circulation path does not exceed the available static

pressure and that velocities does not exceed the

recommended limits cannot be overstated as these

will ensure a quieter system that will deliver the

required capacity to a given space.

It is absolutely overriding for the designer to verify

available static pressure for both supply and return

ducts. The following tables (tables 3 and 4) provide

information about duct sizing (specific to hi-velocity

system) and the redesigned 37AHB series furnaces

respectively.

To employ table 3 the designer must have generated

at least the following information: total system required

airflow (in CFM), and maximum number of 3 inch

diameter supply legs based on 50 CFM per leg.

Table 4 “Specification Sheet” summarizes the

performance and other technical characteristics of the

37AHB series furnaces and their subsystems.

Some specification numbers are generated by

numerical methods and are therefore statistical means

based on the testing of three or more samples.

Use both tables in conjunction with good engineering

practice together with all codes and ordinances having

jurisdiction.

Figure 25:

Recommended Critical Distance between Elbows and 90

O

Tees for a Typical High Velocity System

.

Figure 26:

Recommended Critical Distance between Elbows and 90

O

Conical Tees for a Typical High Velocity System.