Installation, Caution – Rinnai 37AHB SERIES User Manual

Page 19

Rinnai Corporation Hydronic Furnace (37AHB) Manual

19

START-UP PROCEDURE (HEATING ONLY):

The following conditions must be met prior to unit start

-up.

Debris from soldering and/or other installation

activities can cause equipment failure. Ensure that all

associated lines and appurtenances are free of debris.

Check to ensure that unit is secure.

Check that blower wheel rotates freely within the scroll

housing.

Check all wiring to ensure that connections are tight.

Check all ductwork and pipe connections to ensure

proper seal.

Check to ensure that all packaging wraps are removed

from equipment.

Ensure that front access doors are properly installed.

Check to ensure proper connections to the appropriate

blower speed tap (Heat /Cool – High and Low). Refer

to Air Delivery and Capacity Charts and/or the

appropriate wiring diagram in this manual.

Perform all safety and start-up checks for Tankless

Water Heater as per manufacturer’s instructions.

Having verified all preceding checks, the Furnace’s

Start-Up Procedure is as follows:

STEP 1:

Purge and fill system; follow appropriate

purging procedure as laid out in this manual in section

titled “Purging and Priming the System”.

STEP 2:

Turn on power supply to Furnace. Caution:

blower and/or circulator may start to operate if

thermostat is on and a call is present.

STEP 3:

Turn thermostat on and switch system to the

heating mode. The thermostat shall be set higher than

the actual room temperature; this will cause the

circulator to energize and initiate the heating cycle. (If

the pump does not start, or the Furnace is not

producing heat, refer to the Troubleshooting Section in

this manual).

STEP 4:

Program room thermostat as desired by

homeowner.

START-UP PROCEDURE (COOLING SYSTEM)

Refer to field supplied evaporator coil and outdoor unit

manufacturer’s Installation Instructions for system

hook-up, start-up instructions and refrigerant charging

method details.

TROUBLESHOOTING BLOWER AND/OR PUMP

MOTOR AND CONTROLS

If blower and/or pump motor does not run:

Turn off power and check the following:

1. Check that door switch is in the CLOSED position.

2. Check 3 amp fuse on Printed Circuit Board (PCB).

3. Check for 24 VAC between COM and 24 VAC on

PCB. If no voltage is present, check transformer.

4. Check all connections for kinks which could cause

loose connections. Ensure connections are secure.

5. Verify that approximately 120 VAC is present

across L1 and L2 (refer to wiring diagrams).

If system still fails to start, refer to Figures 20 through

23 for additional help.

Installation

High voltage is at all times present at motor.

Disconnect power to the Hydronic Furnace before

removing or replacing or servicing motor. Wait at

least 5 min after disconnecting power before opening

motor. Failure to follow this CAUTION could result in

minor personal injury or product and property

damage.

CAUTION

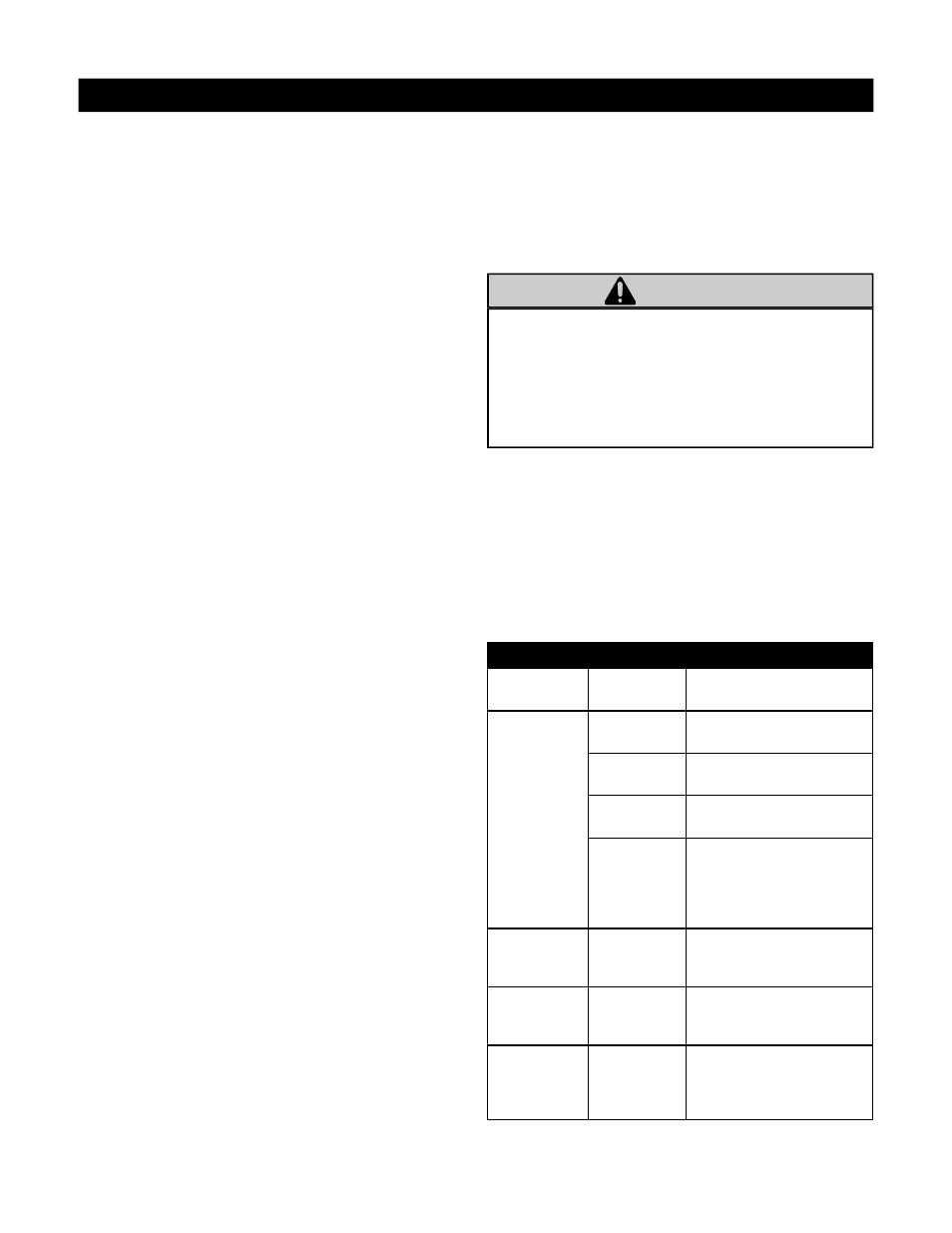

TABLE 2.1: BLOWER MOTOR TROUBLESHOOTING

SYMPTOM

POSSIBLE

CAUSES

CORRECTIVE ACTION

Blown fuse

Turn off motor. Replace

fuse

Incorrect

voltage

Verify motor voltage

matches system voltage

Improper

connections

Turn off motor. Verify

connections

Blower wheel

obstruction

Verify blower wheel is not in

contact with the blower

housing. Readjust blower

wheel position on motor

shaft.

Motor does

not come up

to full speed

Not applied

properly

Check speed taps as per

wiring diagram.

Motor stalls

during

operation

Overload

motor

Check for duct blockage

and/or verify that ducting

system is not restrictive.

Motor vibrates

or is

excessively

noisy

Loose or

defective fan

Turn off motor. Tighten fan

set screw or replace fan.

Motor fails to

start