Raypak 336A User Manual

Page 26

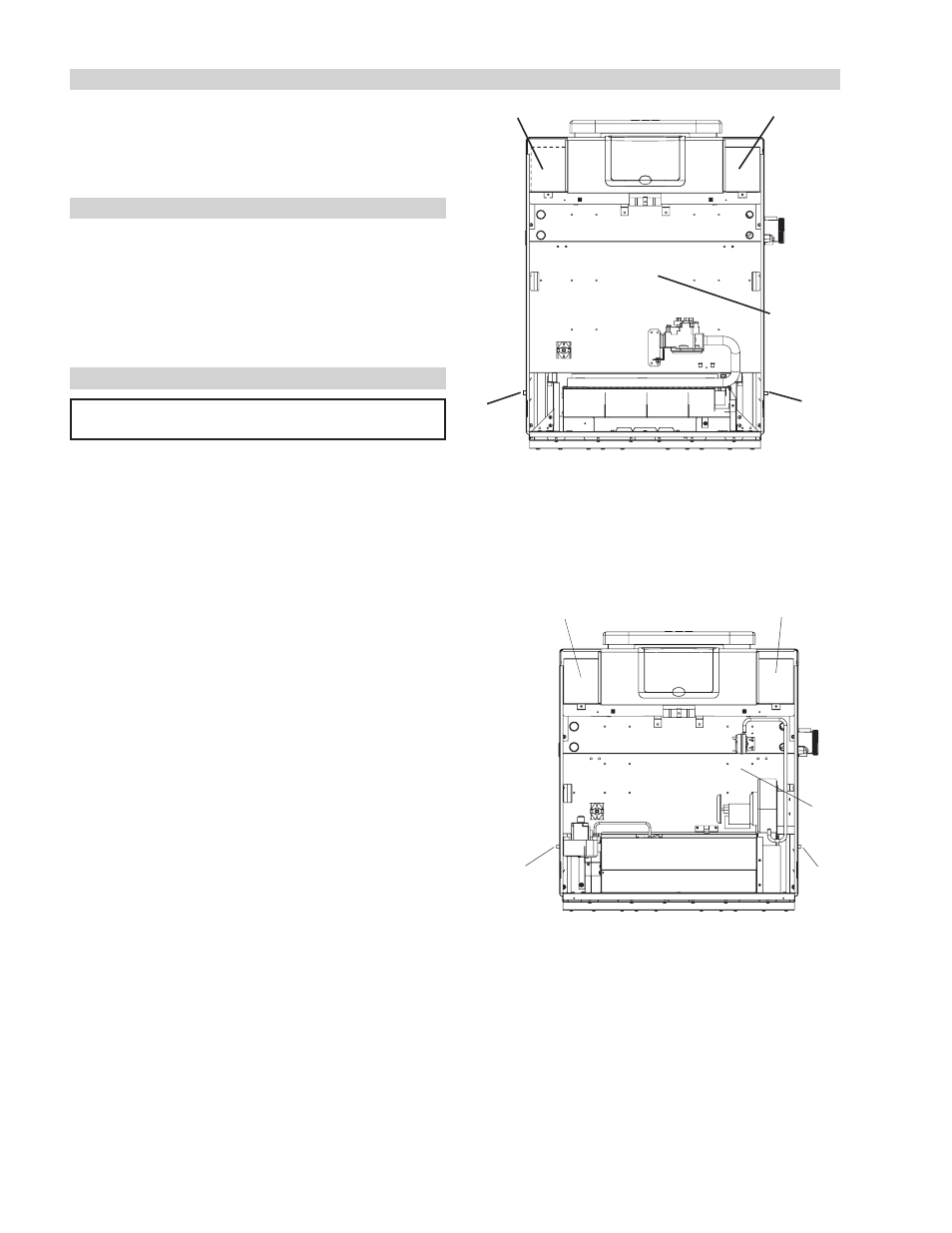

OPTION LOCATION

LEFT SIDE FIELD WIRING

26

ATMOSPHERIC

Wiring locations

LOW NOx

Wiring locations

ELECTRICAL WIRING

NOTE:

If it is necessary to replace any of the original

wiring, use 105°C wire or its equivalent, and/or 150°C

wire or its equivalent, like the original wiring.

MILLIVOLT MODELS

The Millivolt models are equipped with a self-generat-

ing electrical system in which the electrical current is

provided by a pilot generator. No external electrical

connections are required.

When installing a remote switch, do not exceed 10 ft of

wiring from the heater. Use 18-gauge stranded wire.

DIGITAL MODELS

The standard field-wiring connection is on the right

side of the heater.

To wire the heater from the left side, follow these

steps :

1. Remove the two (2) screws that hold the front door

to the heater. Remove and set aside door for bet-

ter access to wiring.

2. Remove the four (4) screws that hold down the

junction box to the sway brace.

3. Remove the transformer cover located on the far

right by removing one (1) screw.

4. Remove the two (2) screws that hold down the

transformer.

5. Remove the one (1) screw that holds down the

ground wires.

6. Disconnect P6 connector from PC board.

7. Remove transformer from its current location and

relocate it on the far left side of the heater.

8. Re-route all high-voltage wires and ground wires

through the left jacket side of heater.

9. Re-install P6 connector, ground wires (SPG),

transformer, junction box, front door, and plug right

side with the left sideʼs grommet plug.

NOTE:

7/8" dia. holes not utilized on jacket and control

box can be used for fireman switch, auxiliary control

interface or power vent (D-2) wiring.

NOTE:

Heater must be electrically grounded and

bonded. Bonding lug is provided loose with the heater.

Install bonding lug on lower right or left side of jacket

as necessary for bonding the heater. Mounting hole is

provided on the jacket.

NOTE:

Heaters are factory-wired for 240 VAC power supply.

The Electronic Intermittent Ignition Device automati-

cally lights the pilot and main burners upon a call for

heat. The heater is supplied with a dual-voltage trans-

former for 120 VAC or 240 VAC input power hookup.

OPTION LOCATION

LEFT SIDE FIELD WIRING

CONTROL BOX

(FACTROY MOUNTED

LOCATION)

SWAY BRACE

BONDING LUG

(STANDARD

LOCATION)

BONDING LUG

(OPTIONAL

LOCATION)

CONTROL BOX (FACTORY

MOUNTED LOCATION)

SWAY

BRACE

BONDING

LUG

(OPTIONAL

LOCATION)

BONDING

LUG

(STANDARD

LOCATION)