Installation – Zanussi ZGL 643 ITX User Manual

Page 16

Installation

Warning! The following instructions about

installation, connection and maintenance must be

carried out by qualified personnel in compliance with

standards and local regulations in force.

Gas Connection

It is necessary that the connection to the gas mains are

carried out by means of an AGB tap. Choose fixed con-

nections or use a flexible pipe in AGB (stainless steel) in

compliance with the regulation in force. If you use flexible

metallic pipes, be careful they do not come in touch with

mobile parts or they are not squeezed. Also be careful

when the hob is put together with an oven.

The connection must be done according to regulation

NBN D 5I.003.

Important! Make sure that the gas supply pressure of the

appliance obeys the recommended values. The adjustable

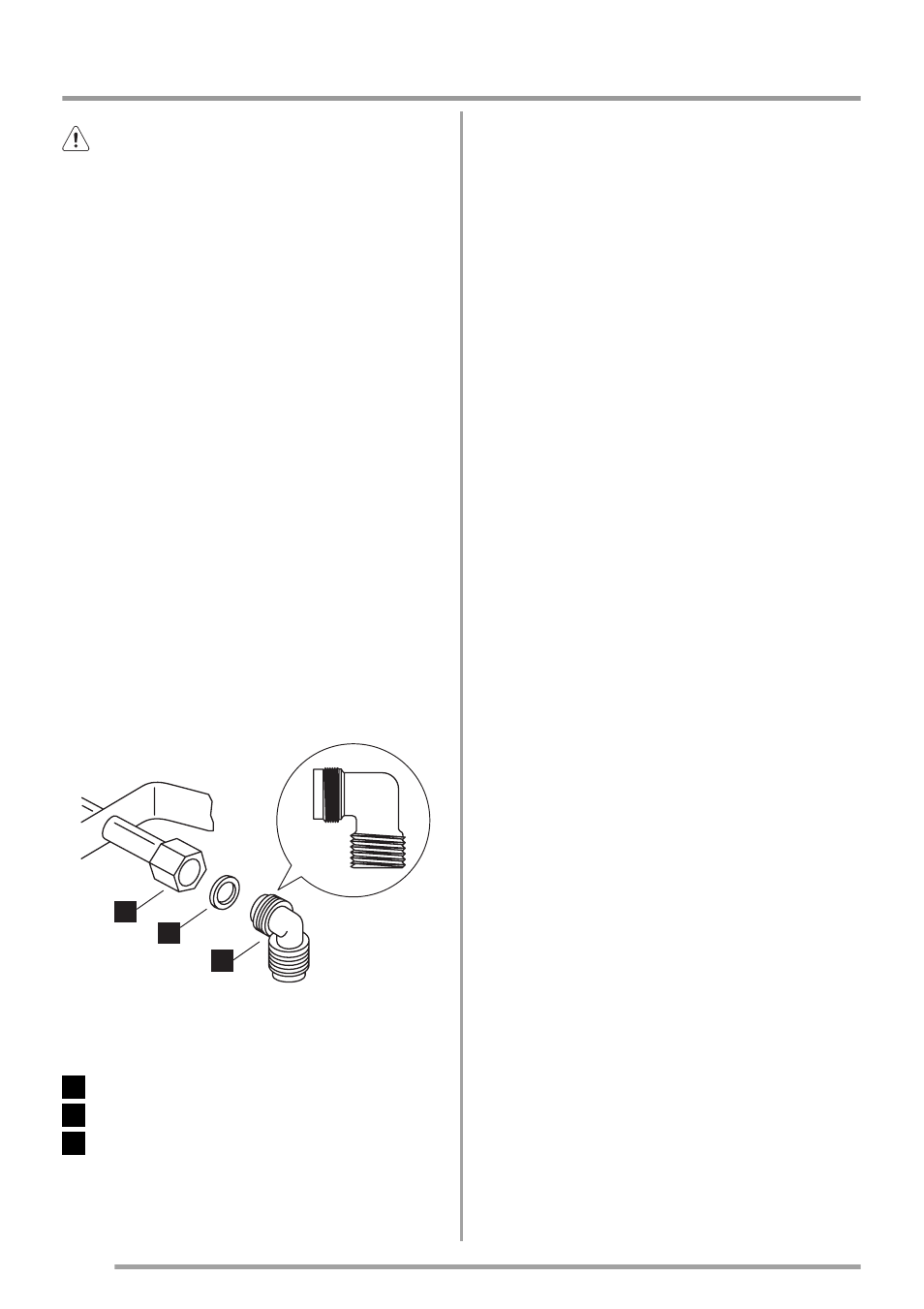

connection is fixed to the comprehensive ramp by means

of a threaded nut G 1/2". All the components shown in the

figure have already been assembled in the factory. The

appliance, before leaving the factory, has been tested in

order to give you the best results.

1

2

3

1

End of shaft with nut

2

Washer

3

Elbow

Flexible nonmetal pipes connection:

If it is possible to easily control the connection in its full

area, you can use a flexible pipe. Tightly attach the flexible

pipe by clamps.

Liquid gas: use the rubber pipe holder. Always engage the

gasket. Then continue with the gas connection. The flexi-

ble pipe is prepared for apply when:

– it can not get hot more than room temperature, higher

than 30°C;

– it is no longer than 1500 mm;

– it shows no throttles;

– it is not subject to traction or torsion;

– it does not get in touch with cutting edges or corners;

– it can be easily examined in order to check its condi-

tion.

The control of preservation of the flexible pipe consists in

checking that:

– it does not show cracks, cuts, marks of burnings on the

two ends and on its full length;

– the material is not hardened, but shows its correct

elasticity;

– the fastening clamps are not rusted;

– expired term is not due.

If one or more defects are visible, do not repair the pipe,

but replace it.

Important! When installation is complete, make sure that

the seal of each pipe fitting is correct. Use a soapy

solution, not a flame!

Injectors replacement

1. Remove the pan supports.

2. Remove the caps and crowns of the burner.

3. With a socket spanner 7 remove the injectors and re-

place them with the ones which are necessary for the

type of gas you use (see table in Technical Data sec-

tion).

4. Assemble the parts, follow the same procedure back-

wards.

5. Replace the rating label (it is near the gas supply

pipe) with the one for the new type of gas supply. You

can find this label in the package of the injectors sup-

plied with the appliance.

16