Getting to know your drill press (continued), Basic drill press operation – RIDGID SP6490 User Manual

Page 30

30

Getting To Know Your Drill Press (continued)

- Use the spindle speed recom-

mended for the specific operation

and workpiece material - check the

inside of the belt guard for drilling

information; for accessories, refer

to the instructions provided with

the accessories.

• Never climb on the drill press table,

it could break or pull the entire drill

press down on you.

• Turn the motor switch off and put

away the switch key when leaving

the drill press.

• To reduce the risk of injury from

thrown work or tool contact, do not

perform layout, assembly or setup

work on the table while the cutting

tool is rotating.

• Don’t overreach. Keep proper foot-

ing and balance at all times.

• Maintain tools with care. Keep tools

sharp and clean for best and safest

performance. Follow instructions for

lubricating and changing accesso-

ries.

Use Only Accessories Designed For This Drill Press To Reduce

the Risk of Serious Injury From Thrown Broken Parts Or Work

Pieces

• When cutting large diameter holes:

- Clamp the workpiece firmly to the

table. Otherwise the cutting may

grab and spin it at high speed.

- Use only one piece, cup-type, hole

cutters.

- Do not use fly cutters or multi-part

hole cutters as they can come

apart or become unbalanced in

use.

- Keep speed below 1500 R.P.M.

• Drum sanders must never be oper-

ated on this drill press at a speed

greater than 1800 R.P.M.

• Do not install or use any drill that

exceeds 7” in length or extends 6”

below the chuck jaws. They can

suddenly bend outward or break.

• Do not use wire wheels, router bits,

shaper cutters, circle (fly) cutters or

rotary planers on this drill press.

Basic Drill Press Operation

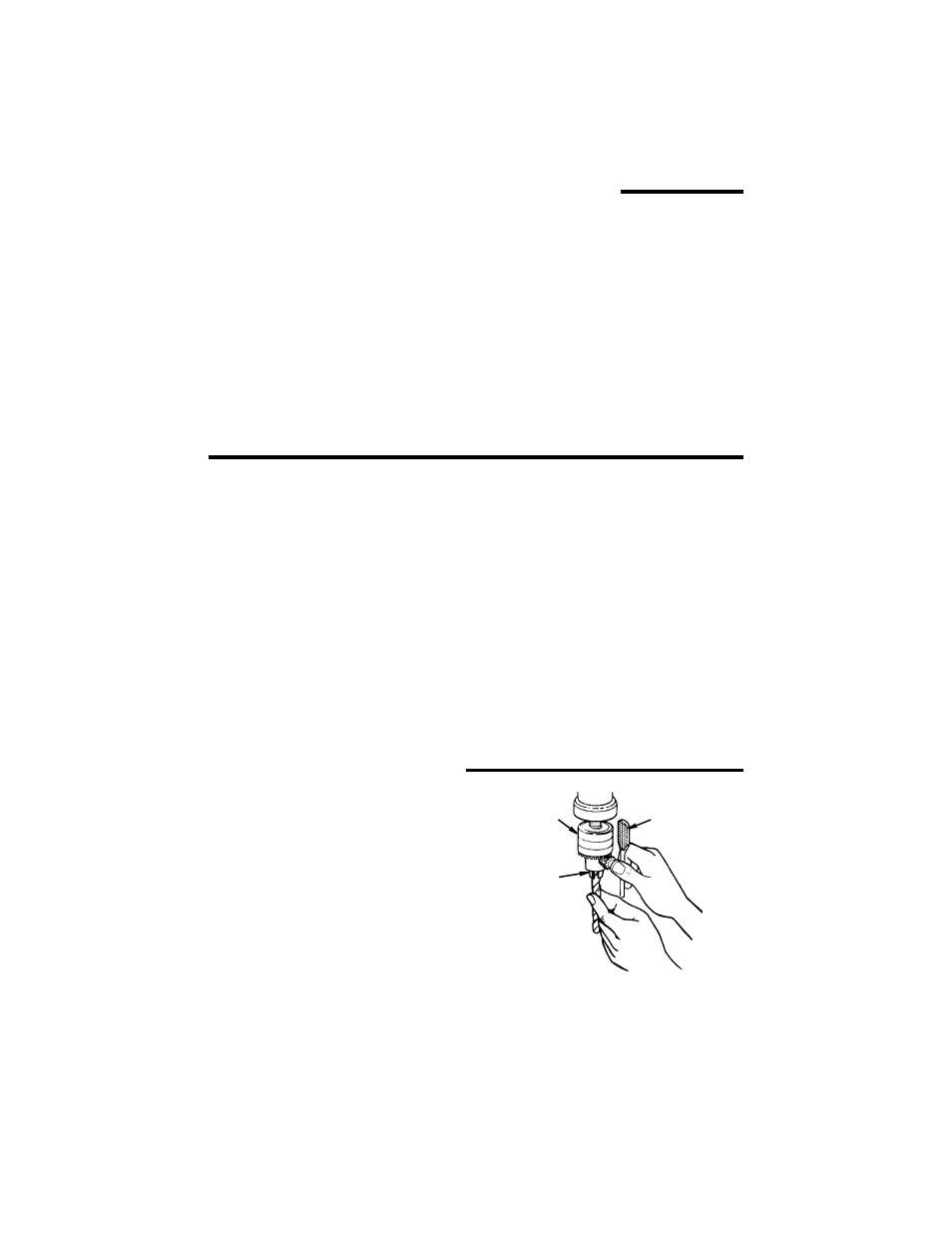

Installing Drills

Insert drill into chuck far enough to obtain

maximum gripping of the chuck jaws. The

jaws are approximately 1" long. When

using a small drill do not insert it so far

that the jaws touch the flutes (spiral

grooves) of the drill. Make sure that the

drill is centered in the chuck before tight-

ening the chuck with the key.

Tighten the drill sufficiently, so that is does

not slip while drilling.

Turn the chuck key clockwise to tighten,

counterclockwise to loosen.

Chuck Key

Chuck

Jaws