Rinnai RC80HPI User Manual

Page 14

14

Manual - Rinnai Condensing Water Heaters

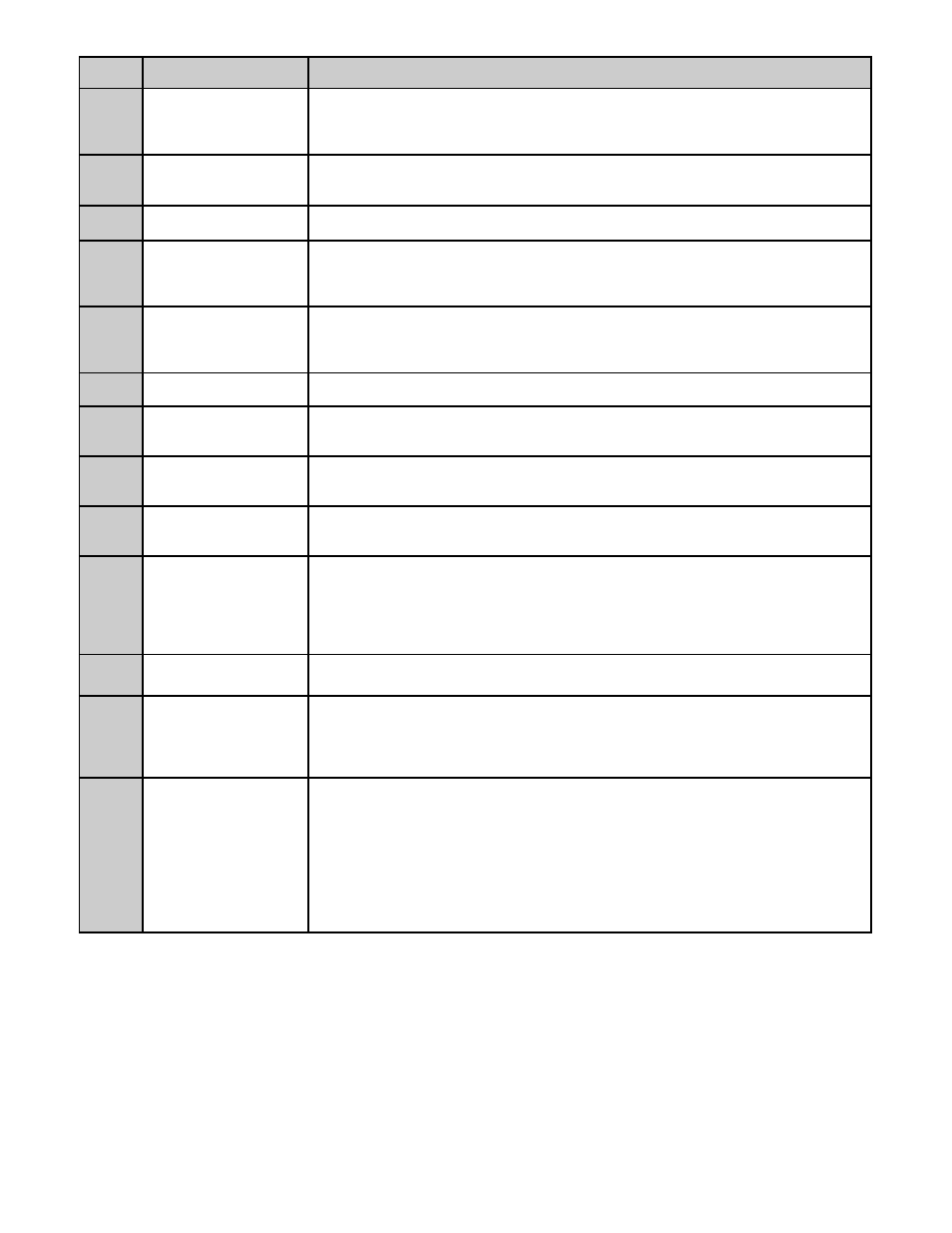

Code

Fault

Remedy

16

Over Temperature

Warning

Check for restrictions in air flow around unit and vent terminal.

Check for low water flow in a circulating system causing short-cycling.

Check for foreign materials in combustion chamber and/or exhaust piping.

Check for clogged heat exchanger.

25

Condensate Trap Error

Condensate container is full.

Check condensate drain for blockage.

Replace condensate trap.

31

Burner Sensor Error

Measure resistance of sensor.

Replace sensor.

32

Outgoing Water

Temperature Sensor

Fault

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Replace sensor.

33

Heat Exchanger

Outgoing Temperature

Sensor Fault

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Replace sensor.

52

Modulating Solenoid

Valve Signal Abnormal

Check modulating gas solenoid valve wiring harness for loose or damaged terminals.

Measure resistance of valve coil.

61

Combustion Fan

Failure

Ensure fan will turn freely.

Check wiring harness to motor for damaged and/or loose connections.

Measure resistance of motor winding.

65

Water Flow Control

Fault

The water flow control valve has failed to close during the bath fill function. Immediately turn off

the water and discontinue the bath fill function. Contact a state qualified or licensed contractor to

service the appliance.

71

SV0, SV1, SV2, SV3

and SV4 Solenoid

Valve Circuit Fault

Replace the PC board.

72

Flame Sensing Device

Fault

Ensure flame rod is touching flame when unit fires.

Check all wiring to flame rod for damage.

Remove flame rod and check for carbon build-up; clean with sand paper.

Check inside burner chamber for any foreign material blocking flame at flame rod.

Measure micro amp output of sensor circuit with flame present.

Replace flame rod.

73

Burner Sensor Circuit

Error

Check sensor wiring and PC board for damage.

Replace sensor.

LC

Scale Build-up in Heat

Exchanger (when

checking maintenance

code history, “00” is

substituted for “LC”)

Flush heat exchanger. Refer to instructions in manual.

Replace heat exchanger.

NOTE: The LC code is the only error code that will allow the unit to keep running. The display will

alternate between the LC code and the temperature setting. The controller will continue to beep.

The LC code will reset if power is turned off and then on.

No

code

Nothing happens when

water flow is activated.

Clean inlet water supply filter.

On new installations ensure hot and cold water lines are not reversed.

Check for bleed over. Isolate unit from building by turning off hot water line to building. Isolate the

circulating system if present. Open your pressure relief valve; if water is flowing, there is bleed

over in your plumbing.

Ensure you have at least the minimum flow rate required to fire unit.

Ensure turbine spins freely.

Measure the resistance of the water flow control sensor.

Check for DC shorts at components.