Venting – Raypak 399B-2339B User Manual

Page 25

25

Venting

General

Flue Exhaust Tee

An optional Flue Exhaust Tee is available to facilitate

horizontal venting. Any reference to horizontal venting

that exits the back of the heater requires this tee. Refer

to Table J for the appropriate kit for your model.

CAUTION: Proper installation of flue venting is criti-

cal for the safe and efficient operation of the heater.

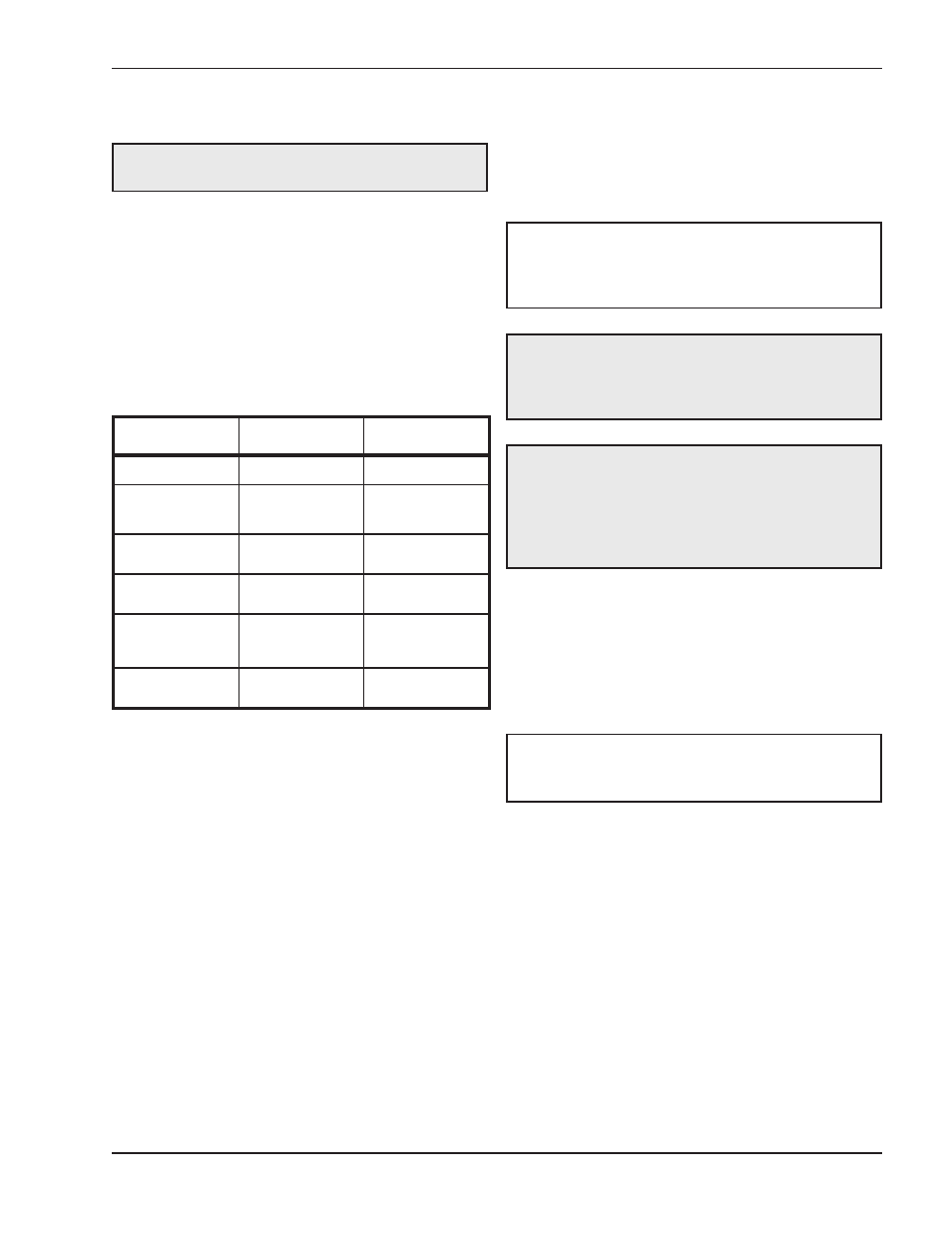

Table J: Flue Exhaust Tee Kits

Model

Diameter

Order Number

399B–499B

6”

011839

649B, 749B,

899B

8”

011840

989B

10”

011841

1259B, 1529B

12”

011842

1799B, 1999B,

2069B

14”

011843

2339B

16”

011844

Category IV – A heater which operates with a positive

vent pressure and with a vent gas temperature that

may cause excessive condensate production in the

vent.

See Table K for appliance category requirements.

Support of Vent Stack

The weight of the vent stack or chimney must not rest

on the heater vent connection. Support must be pro-

vided in compliance with applicable codes. The vent

should also be installed to maintain proper clearances

from combustible materials.

Barometric Damper

A barometric damper may be required when vent

heights exceed 25 feet or when the draft is greater

than -0.08 in. WC. In these installations, a barometric

damper (single or double acting) is recommended.

The damper should be installed NO CLOSER than 18

in. from the discharge of the unit and no closer than 18

in. from a combustible ceiling. The damper can be

installed in horizontal or vertical runs of vent pipe as

necessary. Installation in a bull-head tee is acceptable

as shown in the NFGC.

The weights on the damper should be adjusted per the

damper manufacturer’s instructions for proper opera-

tion.

Appliance Categories

Heaters are divided into four categories based on the

pressure produced in the exhaust and the likelihood of

condensate production in the vent.

Category I – A heater which operates with a non-pos-

itive vent static pressure and with a vent gas

temperature that avoids excessive condensate pro-

duction in the vent.

Category II – A heater which operates with a non-pos-

itive vent static pressure and with a vent gas

temperature that may cause excessive condensate

production in the vent.

Category III – A heater which operates with a positive

vent pressure and with a vent gas temperature that

avoids excessive condensate production in the vent.

NOTE: For additional information on appliance

categorization, see appropriate ANSI Z21 Standard

and the NFGC (U.S.), or B149 (Canada), or

applicable provisions of local building codes.

CAUTION: When condensate traps are installed,

condensate must be routed to an appropriate

container for neutralization before disposal, as

required by local codes.

WARNING: Contact the manufacturer of the vent

material if there is any question about the appliance

categorization and suitability of a vent material for

application on a Category III or IV vent system.

Using improper venting materials can result in

personal injury, death or property damage.

NOTE: During winter months check the vent cap

and make sure no blockage occurs from build-up of

snow or ice.