Power drive inspection, Accessories – RIDGID 690 User Manual

Page 6

Ridge Tool Company

4

Switches

ON/OFF.......................Heavy Duty Paddle Type with

Safety Locking Device

Directional .....................FOR/REV Switch

Gear Head.....................Die Cast Aluminum Housing,

Permanently Greased

Length ...........................24

″

(61cm)

Weight ...........................19 lbs. (8.6 kg)

No. 691 Support Arm.....Absorbs Power Drive Handle

Forces

Die Head Adapter..........Used with

1

/

8

″

through 1

1

/

4

″

Die Heads

Accessories

No. 11-R Die Heads (9)...

1

/

8

″

,

1

/

4

″

,

3

/

8

″

,

1

/

2

″

,

3

/

4

″

, 1

″

, 1

1

/

4

″

,

1

1

/

2

″

, 2

″

No. 418 Oiler .................Oiler with 1 Gallon RIDGID

Thread Cutting Oil

No. 691 Support Arm.....Absorbs Power Drive Handle

Forces

Carrying Case .................For Power Drive and Die

Heads

Die Head Adapter ...........Used with

1

/

8

″

through 1

1

/

4

″

Die

Heads

Power Drive Inspection

WARNING

To prevent serious injury, inspect your Power

Drive. The following inspection procedures should

be performed on a daily basis:

1. Make sure Power Drive is unplugged.

2. Inspect the power cord and plug for damage. If the

plug has been modified or if the cord is damaged, do

not use the Power Drive until the cord has been

replaced.

3. Inspect the Power Drive for any broken, missing,

misaligned or binding parts as well as any other con-

ditions which may affect the safe and normal opera-

tion of the tool. If any of these conditions are present,

do not use the Power Drive until any problem has

been repaired.

4. Use tools and accessories that are designed for your

Power Drive and meet the needs of your applica-

tion. The correct tools and accessories allow you to do

the job successfully and safely. Accessories suitable

for use with other equipment may be hazardous

when used with this Power Drive.

5. Clean any oil, grease or dirt from all equipment han-

dles and controls. This reduces the risk of injury due

to a tool or control slipping from your grip.

6. Inspect the cutting edges of your dies. If necessary,

have them replaced prior to using the Power Drive.

Dull or damaged dies can lead to binding and poor

quality threads.

7. Clean metal shavings and other debris from the chip

pan of the 418 Oiler. Check the level and quality of the

thread cutting oil. Replace or add oil if necessary.

NOTE! Thread cutting oil lubricates and cools the threads

during the threading operation. A dirty or poor

grade cutting oil can result in poor thread quality.

No. 690 Portable Power Drive

Catalog Model

Weight

No. No.

Description

lb.

kg.

16708

690

115V Kit less Die Heads

35

15.8

w/Case and Support Arm

16013

690

115V

1

/

2

″

- 2

″

NPT 52.5

24

w/Case and Support Arm

16718

690

220V,

1

/

2

″

- 2

″

NPT w/Support Arm, Export 52.5

24

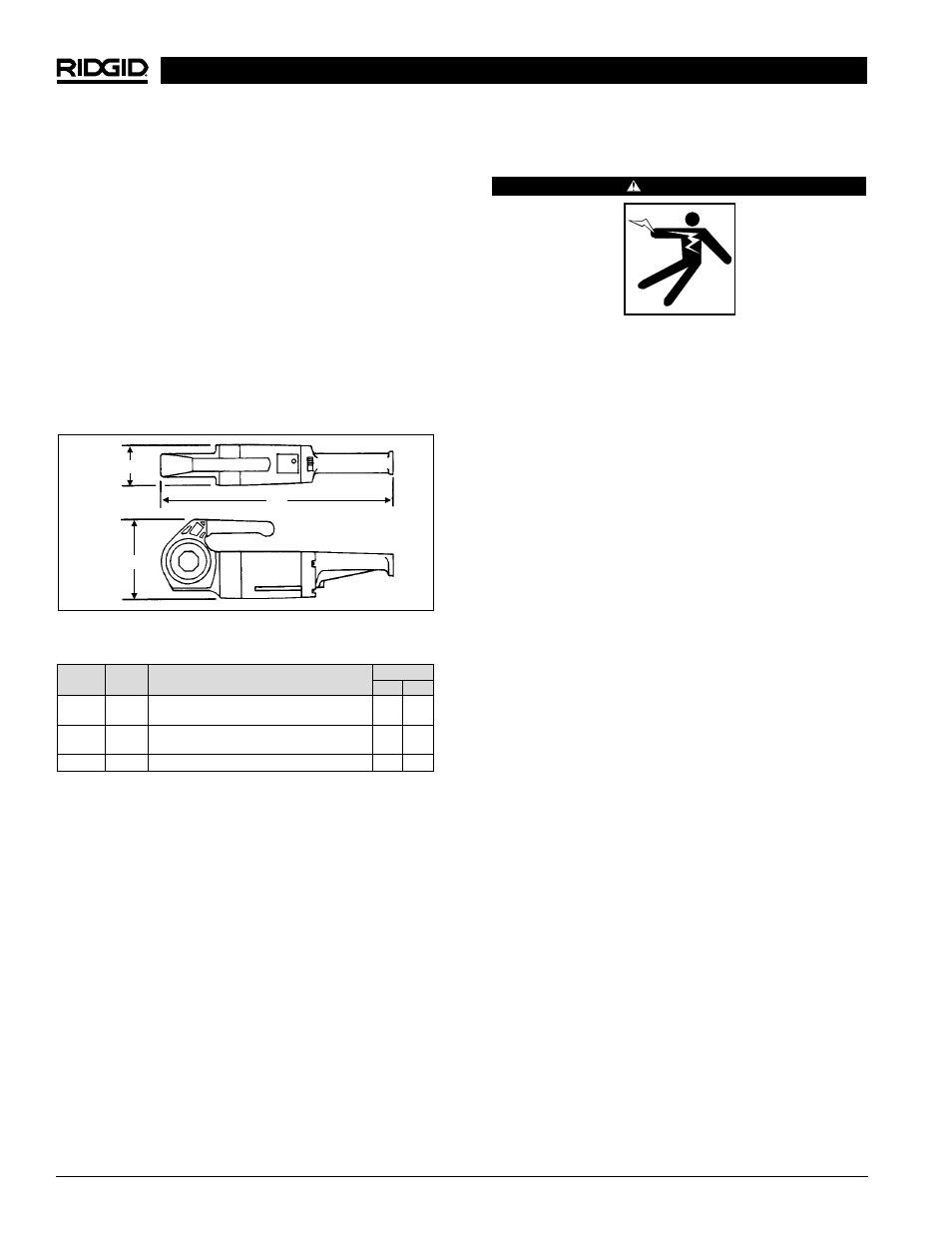

Figure 1 – 690 Power Drive Dimensions

5

″

24

″

9

″