Vertical venting installation gas installation, Restricting vertical vents – Napoleon Fireplaces PARK AVENUE GD82PT User Manual

Page 14

14

W415-0536 / B / 07.20.06

FLUE COLLAR

RESTRICTOR PLATE

TOP OF THE

FIREBOX

Proceed once the vent installation is complete.

Note : All gas connections must be contained within

the fi replace when complete.

1. The fi replace is designed to accept a ½” gas supply line.

The fi replace is equipped with a ½” manual shut-off valve, and

an 18” listed fl exible gas connector.

2. The access to the gas inlet is

located on the right side of the outer

shell.

3. The fl ex connector and shut off

must all be within the outer shell.

4. When fl exing any gas line, sup-

port the gas valve so that the lines

are not bent.

5. Check for gas leaks by brushing

on a soap and water solution. Do not

use open fl ame.

1. Move the fi replace into position.

2. Fasten the roof support to the roof using the screws

provided. The roof support is optional. In this case the vent-

ing is to be adequately supported using either an alternate

method suitable to the authority having jurisdiction or the

optional roof support.

3. Apply high temperature seal-

ant to the outer edge of the inner

sleeve of the air terminal. Slip a 4”

diameter coupler a minimum of 2”

over the sleeve and secure using

3 screws.

4. Apply high temperature seal-

ant to the outer edge of the of the

outside sleeve of the air terminal.

Slip a 7” diameter coupler over

the sleeve and secure as before.

Trim the 7” coupler even with the

4” coupler end.

5. Thread the air terminal pipe

assembly down through the roof

support and attach, ensuring that

a minimum 16” of air terminal will

penetrate the roof when fastened.

The air terminal must be located

vertically and plumb.

6. Remove nails from the shin-

gles, above and to the sides of

the chimney. Place the fl ashing

over the air terminal and slide it

underneath the sides and upper edge of the shingles. Ensure

that the air terminal is properly centred within the fl ashing, giv-

ing a 3/4” margin all around. Fasten to the roof. Do NOT nail

through the lower portion of the fl ashing. Make weather-tight

by sealing with caulking. Where possible, cover the sides and

top edges of the fl ashing with roofi ng material.

7. Apply a heavy bead of waterproof caulking 2 inches

above the fl ashing. Slide the storm collar around the air ter-

minal connector and down to the caulking. Tighten to ensure

that a weather-tight seal between the air terminal and the

collar is achieved.

8. Continue adding rigid venting sections, sealing and

securing as above. Attach a 4” collapsed telescopic pipe to

the last section of rigid piping. Secure with screws and seal.

Repeat using a 7” telescopic pipe.

9. Run a bead of high temperature sealant around the

outside of the 4” collar on the fi replace. Pull the adjustable

pipe a minimum of 2” onto the collar. Secure with 3 screws.

Repeat with the 7” telescopic pipe.

10. In the attic, slide the vent pipe collar down to cover up

the open end of the shield and tighten. This will prevent any

materials, such as insulation, from fi lling up the 1” air space

around the pipe.

VENT PIPE

SHIELD

VENT

PIPE

COLLAR

FIGURE 24

FIGURE 23

VERTICAL VENTING INSTALLATION

GAS INSTALLATION

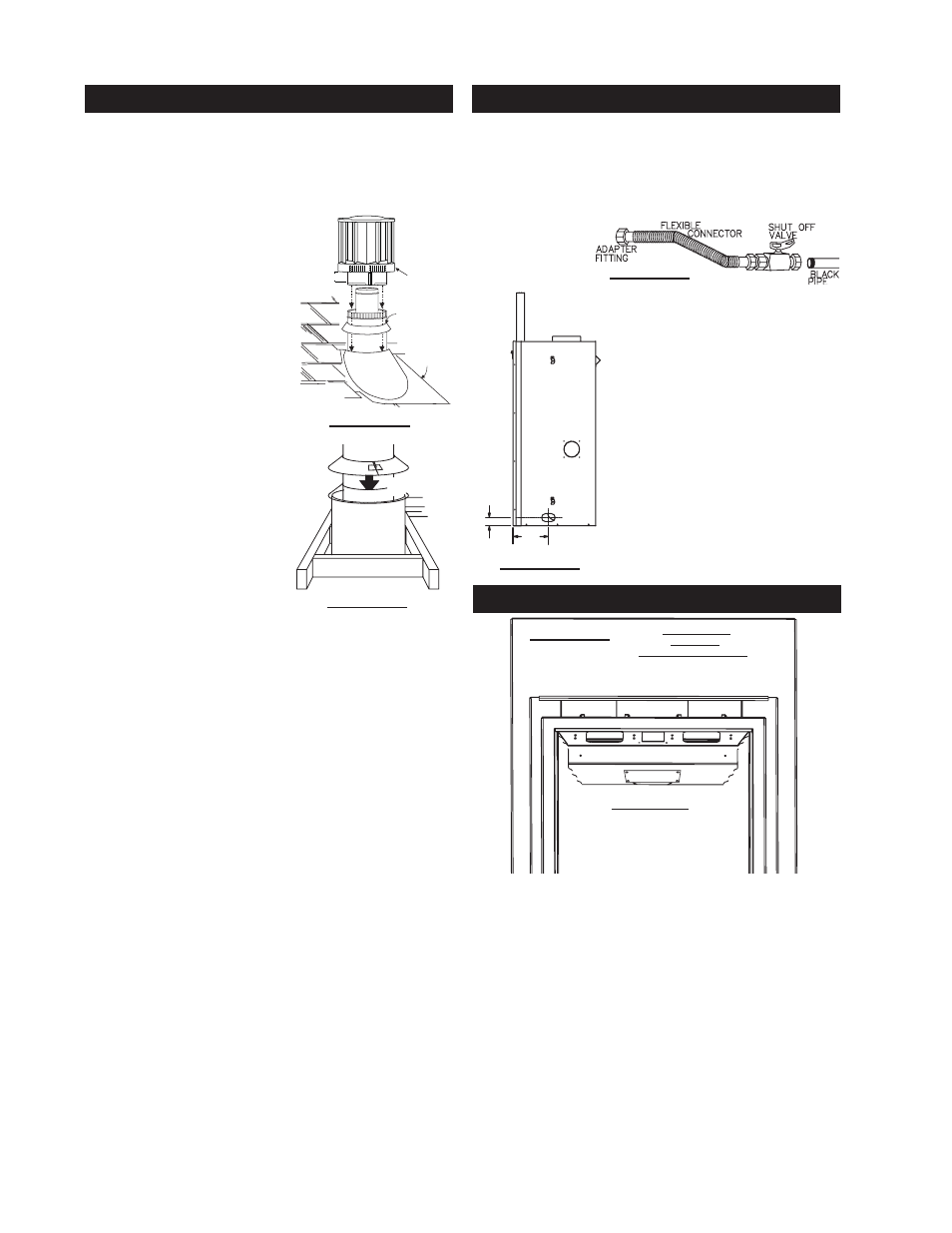

Vertical terminations may display a very active fl ame. If this

appearance is not desirable, the vent exit must be restricted

using restrictor plate, W500-0205. This reduces the velocity

of the exhaust gases, slowing down the fl ame pattern and

creating a more traditional appearance.

The plate has a series of holes to allow for adjustment.

Remove the two screws on either side of the exhaust collar

inside the fi rebox. Install the plate in the desired set of holes,

then replace the screws.

It is recommend to secure in the third set of holes which

causes the greatest amount of restriction for vent length

between 15 and 30 feet.

RESTRICTING VERTICAL VENTS

FIGURE 25

FIGURE 26

FIGURE 27

2"

8

7

/

8

"

STORM COLLAR

FLASHING

CAULKING

WEATHER

SEALANT

2”

AIR INLET

BASE