Using flexible vent components, Figure 18, Figure 19a,b&c – Napoleon Fireplaces PARK AVENUE GD82PT User Manual

Page 12: Figure 17

12

W415-0536 / B / 07.20.06

Spacers are attached to the inner fl ex liner at predetermined intervals to maintain a 1-1/4” air

gap to the outer fl ex liner. These

spacers must not be removed.

1. Fasten the roof support to the

roof using the screws provided.

The roof support is optional. In

this case the venting is to be ad-

equately supported using either an

alternate method suitable to the

authority having jurisdiction or the

optional roof support. (Fig.a)

2. Stretch the inner aluminum

fl ex liner to the required length.

Slip the liner a minimum of 2” over the inner sleeve of the

air terminal connector and secure

with 3 #8 screws. Seal using a

heavy bead of the high temperature

sealant. (Fig.b)

3. Repeat using the outer aluminum

fl ex liner. (Fig.b)

4. Thread the air terminal connector

/ liner assembly down through

the roof. The air terminal must

be located vertically and plumb.

Attach the air terminal connector to

the roof support, ensuring that the

top of the air terminal is 16” above

the highest point that it penetrates

the roof. (Fig.c) If the attic space is

tight, we recommend threading

the Wolf Steel vent pipe collar or

equivalent loosely onto the air

terminal assembly as it is passed

through the attic.

wall and make weather tight by

5. Apply a heavy bead of the

high temperature sealant, (W573-

0007 not provided), to the inside of

the 4” liner approximately 1” from

the end. Slip the liner a minimum

of 2” over the fi replace vent collar

and secure with 3 #8 screws.

6. Using the 7” diameter fl exible

aluminium liner,

apply sealant,

slide a mini-

mum of 2” over

t h e f i r e p l a c e

combustion air

collar and se-

cure with 3 #8

screws.

1. Cut or frame a hole in an exterior wall with a minimum

round or square opening of 11

1

/

2

” W x 11

1

/

2

” H. Secure the

fi restop spacer over the opening to the interior wall.

Secure the terminal to the terminal extension plate if required

(see fi gure 18). The cover plate of the GD-222R terminal is

13”x13” and will cover the 11 1/2” x 11 1/2” opening but if the

opening is made any larger - the terminal extension plate is

required.

2. Stretch the 4” diameter aluminum fl exible liner to the

required length taking into account the additional length

needed for the fi nished wall surface. Slip the liner a minimum

of 2” over the inner sleeve of the air terminal and secure with

3 #8 screws. Apply a heavy bead of the high temperature

sealant.

3. Using the 7” diameter fl exible aluminum liner, slide over

the outer combustion air sleeve of the air terminal and secure

with 3 #8 screws. Seal as before.

4. Insert the liners through the fi restop maintaining the

required clearance to combustibles. Secure to the exterior

4

7

7

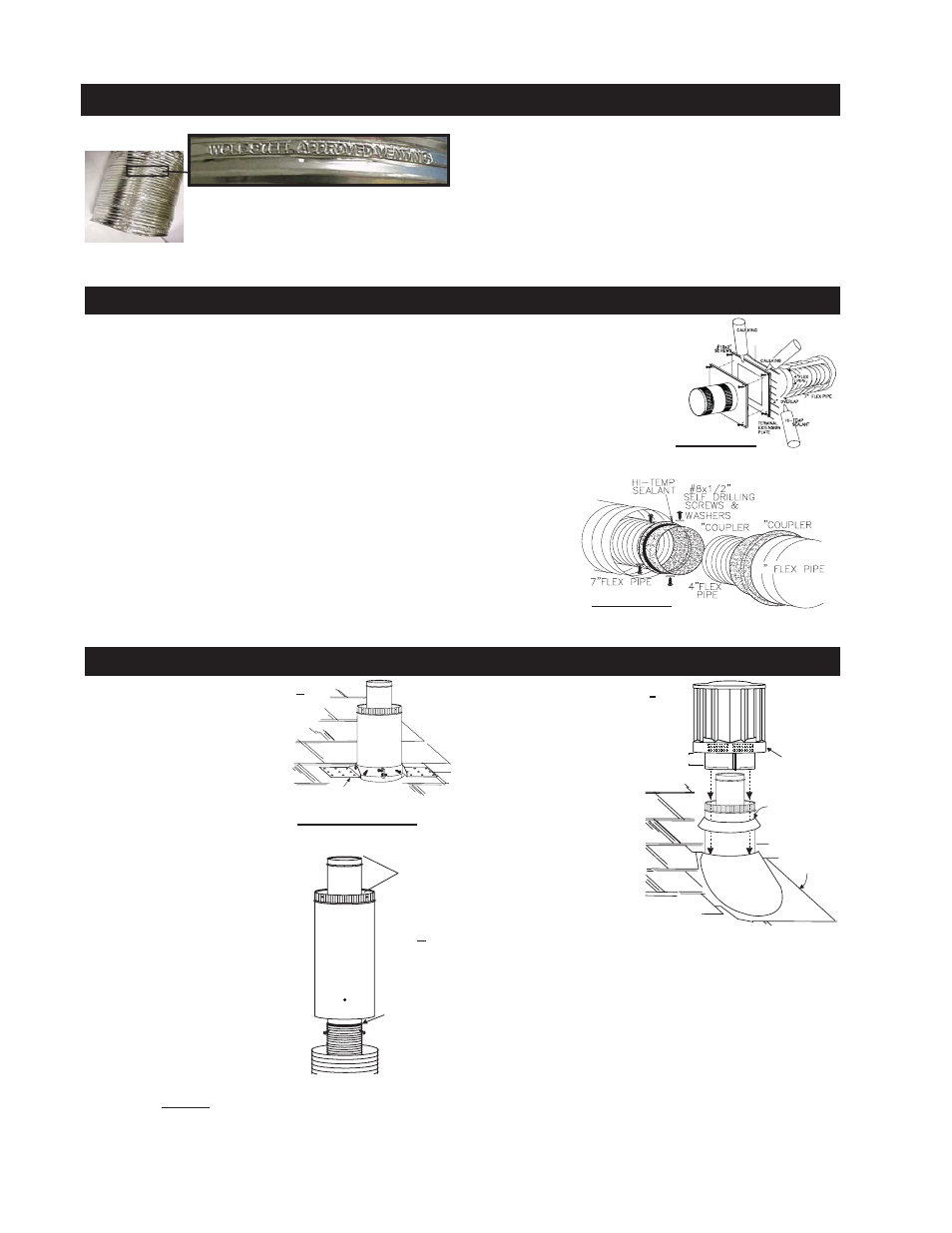

FIGURE 18

Use only approved aluminum flexible liner kits

marked:

“Wolf Steel Approved Venting” as

identifi ed by the stamp only on the

USING FLEXIBLE VENT COMPONENTS

HORIZONTAL AIR TERMINAL INSTALLATION

For safe and proper operation of the fi replace, follow the

venting instructions exactly.

All inner exhaust and outer intake vent pipe joists may

be sealed using either Red RTV high temp silicone seal-

ant or Black high temp Mill Pac with the exception of the

fi replace exhaust fl ue collar which must be sealed using

Mill Pac (not supplied).

VERTICAL AIR TERMINAL INSTALLATION

FIGURE 19a,b&c

ROOF SUPPORT

a

DO NOT CLAMP THE

FLEXIBLE

ALUMINIUM LINER.

AIR

TERMINAL

CONNECTOR

INNER FLEX

LINER

OUTER FLEX

LINER

INNER

SLEEVE

HIGH

TEMPERATURE

SEALANT

b

STORM COLLAR

FLASHING

CAULKING

WEATHER

SEALANT

2”

AIR INLET

BASE

c

CAULKING

SCREWS

#10x2"

PIPE

7" FLEX

2" OVERLAP

4"FLEX

PIPE

SEALANT

HI-TEMP

TERMINAL

EXTENSION

PLATE

CAULKING

FIGURE 17

5. Remove nails from the

shingles, above and to the

sides of the chimney. Place

the fl

ashing over the air

terminal connector leaving a

min. 3/4” of the air terminal

connector showing above

the top of the fl ashing. Slide

the fl ashing underneath the

sides and upper edge of

the shingles. Ensure that

the air terminal connector

is properly centred within

the fl ashing, giving a 3/4”

margin all around. Fasten to

the roof. Do not nail through

the lower portion of the

fl ashing. Make weather-tight by sealing with caulking. Where

possible, cover the sides and top edges of the fl ashing with

roofi ng material. (Fig.c)

6. Aligning the seams of the terminal and air terminal

connector, place the terminal over the air terminal connector

making sure the liner goes into the hole in the terminal.

Secure with the three screws provided. (Fig.c)

7. Apply a heavy bead of weatherproof caulking 2 inches

above the fl ashing. Note: Maintain a minimum 2” space

between the air inlet base and the storm collar. Install the

storm collar around the air terminal connector and slide

down to the caulking. Tighten to ensure that a weather-tight

seal between the air terminal connector and the collar is

achieved. (Fig.c)