Verifying burner operation, Verifying operation of the supply air limit switch, Description of components – Nordyne RL 90+ User Manual

Page 34

34

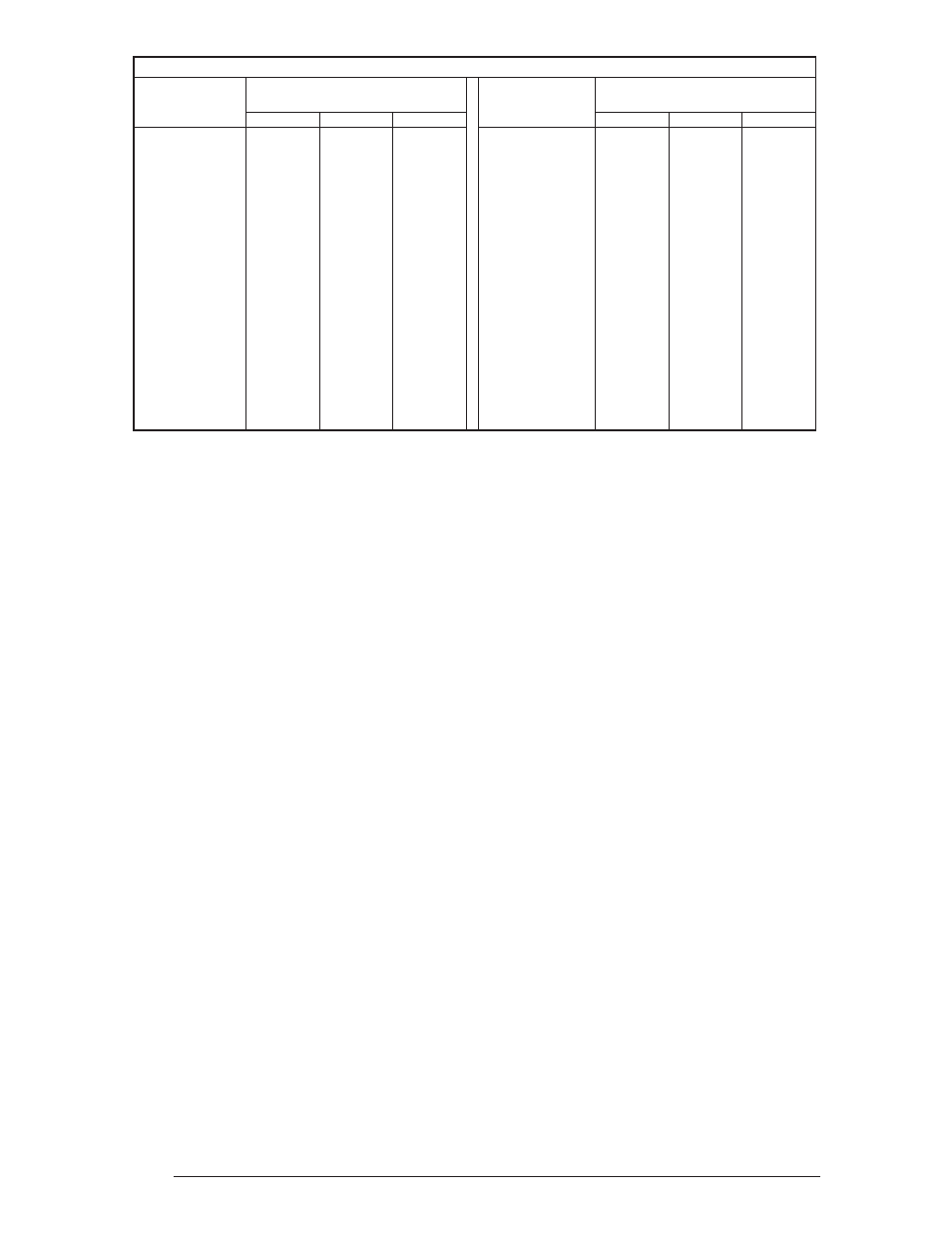

Table 13. Gas Flow Rate

control board. Reconnect the desired blower tap

to the piggyback quick connect.

The blower control is designed to start the

circulating air blower 30 seconds after the gas

valve is opened. The blower control is factory

wired to turn the blower motor off 120 seconds

after the gas valve is closed. This timing can be

changed using the BLOWER OFF timing switch

opposite the terminal block on the control board.

(See Figure 28.)

Verifying Burner Operation

To verify operation of the burners, make sure

that the blower compartment door is in place

and that there is power to the furnace. Set the

thermostat above room temperature and ob-

serve the ignition sequence. The fl ame can be

observed through the small clear window on the

burner box. The burner fl ame should carry over

between all burners. The fl ames should be blue,

without yellow tips. Flames should extend from

each burner without lifting, curling, or fl oating.

After verifying ignition, set the thermostat below

room temperature and verify that the burner fl ame

extinguishes completely.

Verifying Operation of the Supply

Air Limit Switch

To verify operation of the supply air limit switch,

make sure that the blower door is in place and

that there is power to the furnace. Completely

block the return airfl ow to the furnace by installing

a close-off plate in place of or upstream of the

fi lter(s). Set the thermostat above room tempera-

ture and verify that the Sequence of Operation

is as described in these instructions. The supply

air limit switch should function to turn off the

gas valve within approximately fi ve minutes. The

circulating air and combustion blowers should

continue to run when the supply air limit switch

opens. Remove the close-off plate immediately

after the supply air limit switch opens. If the

furnace operates for more than fi ve minutes

with no return air, set the thermostat below room

temperature, shut off the power to the furnace,

and replace the supply air limit switch.

DESCRIPTION OF COMPONENTS

Figure 28 shows the location of each of the

functional components described below. If any

component of the furnace must be replaced,

use only factory authorized replacement parts.

See the Replacement Parts List for each com-

ponent.

Flame Sensor – The fl ame sensor acts to prove

that fl ame has carried over from the igniter to the

opposite end burner. If no fl ame is sensed, the

furnace will be shut down automatically.

Gas Valve – The gas valve controls the fl ow

of gas to the burners. When the gas valve is

energized it automatically opens and regulates

the gas pressure in the manifold.

Pressure Switch – The pressure switch verifi es

that the inducer is drawing the combustion gases

GAS FLOW RATE (CUBIC FEET PER HOUR)

TIME FOR

ONE REVOLUTION

(SECONDS)

CUBIC FEET PER REVOLUTION OF

METER

TIME FOR

ONE REVOLUTION

(SECONDS)

CUBIC FEET PER REVOLUTION OF

METER

1

5

10

1

5

10

24

150

750

1500

80

45

225

450

26

138

692

1385

82

44

220

439

28

129

643

1286

84

43

214

429

30

120

600

1200

86

42

209

419

32

113

563

1125

88

41

205

409

34

106

529

1059

90

40

200

400

36

100

500

1000

92

39

196

391

38

95

474

947

94

38

191

383

40

90

450

900

96

38

188

375

42

86

429

857

98

37

184

367

44

82

409

818

100

36

180

360

46

78

391

783

102

35

176

353

48

75

375

750

104

35

173

346

50

72

360

720

106

34

170

340

52

69

346

692

108

33

167

333

54

67

333

667

110

33

164

327

56

64

321

643

112

32

161

321

58

62

310

621

114

32

158

316

60

60

300

600

116

31

155

310

62

58

290

581

118

31

153

305

64

56

281

563

120

30

150

300