Chapter 6 troubleshooting, Troubleshooting – Powerware FCC 15 User Manual

Page 27

EATON Powerware

®

Modbus

®

Card User’s Guide

S 164201376 Rev C www.powerware.com

23

Chapter 6

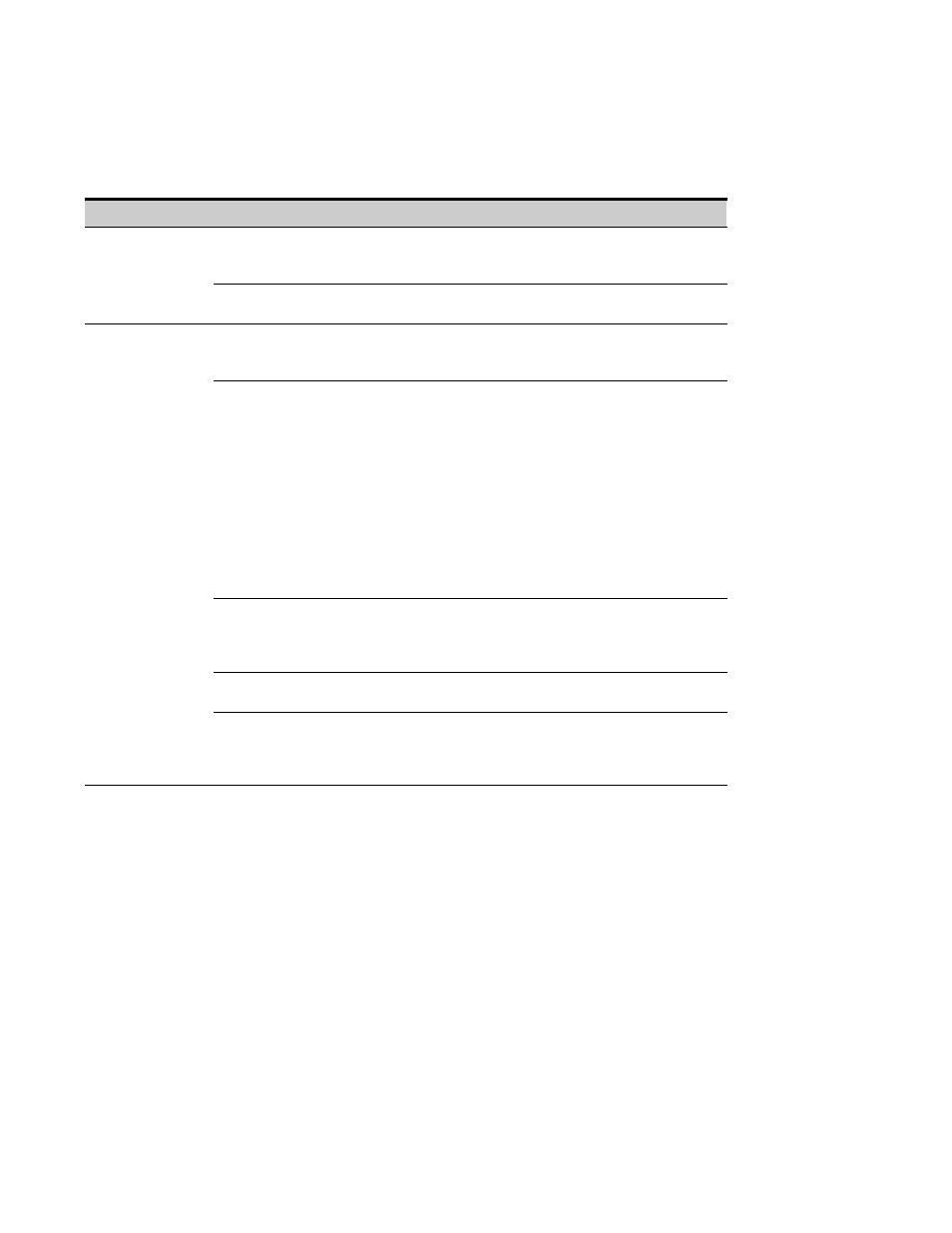

Troubleshooting

Problem

Possible Cause

Corrective Action

The Modbus Profiler

tool does not

generate the

fil

fil

The wrong communication port number was

entered in the profiler comX command.

Verify the correct port number on your

computer that is connected to the Modbus

Card.

g

profiler.csv file

The serial cable is not connected.

Verify that the serial cable connections are

secure.

Communication

doesn’t work

Incorrect communication parameters.

Verify that the communication parameters are

set to the desired baud rate, No parity, 8 data

bits, 1 stop bit, and no hardware handshaking.

RS-485 communication lines are reversed.

For two-wire networks.

Verify that the

master RS-485 network signal TxD(+) is

connected to the Modbus Card RxD(+) input

signal and the RS-485 network signal TxD(–)

is connected to the Modbus Card RxD(–) input

signal.

For four-wire networks.

Verify that all four

RS-485 network signals are connected to the

terminal strip or DB-9 connector as illustrated

in Table 1 on page 9 or Table 2 on page 10,

respectively.

See Chapter 3, “Wiring the Modbus Card” on

page 7 for more information.

If the Modbus Card is the last device installed

in the network chain or the length of the

network cable is excessive, termination

needs to be enabled.

Verify the termination settings (see

“Termination” on page 10 for the correct

settings).

J9 and J10 jumpers could be in the incorrect

position for your configuration.

Verify the jumpers are in the correct position

(see Figure 4 on page 5).

The polling rate in the Building Management

Software (BMS) application or Modbus

software is set below 500 mS.

The Modbus Card updates the status of the

Eaton equipment every 1000 mS. Configure

the BMS/Modbus application polling rate to

500 mS or greater to ensure proper operation.