PVI Industries PV500-45U User Manual

Page 27

27

PV500-45U 06/12

4. Proof of Air Pressure Switch

- The control will look for a signal from the airflow-proving switch, indicating that

the blower is operating:

a. When the airflow generated by the blower is sufficient to cause the differential air switch to close, the 15 -

second pre-purge delay will start.

b. During this period any flue products or combustible gases which may have settled in the water heater are

evacuated.

5. Heat-Up

- Following the pre-purge delay, the hot surface igniter will be energized:

a. The flame control will monitor the current applied to the hot surface igniter.

b. If the flame control determines the proving current meets the threshold, a dwell time delay starts to assure

the hot surface igniter has sufficient time to reach ignition temperature.

6. Ignition

- When dwell time is completed a 4-second Trial for Ignition (TFI) period is initiated:

a. The Delay-On (Low Fire Hold) Relay and the Gas Safety Valves are energized.

b. During TFI the flame safeguard control will monitor the flame using flame rectification through the hot

surface igniter.

c. If the flame control senses the presence of flame before the end of the TFI period, the igniter will be de-

energized and the flame control will continue to monitor the flame, through the igniter, until the operating

thermostat ends the call for heat condition.

7. Loss of Flame Signal

a. If the igniter fails to sense flame at any time, the igniter and gas valve will be de-energized and the flame

control will reset and begin the call-for-heat sequence again. This will occur 3 times (one time if CSD-1)

before the flame control will lockout.

b. When the call for heat condition ends or flame failure occurs following the third TFI period (one time if CSD-

1), a 30-second post-purge period will begin. This period of blower operation will exhaust any remaining

combustion products from the system.

8. Delay-On

Relay

- Once the Delay-On (Low Fire Hold) Relay has timed out, it energizes the Modulation Release

Relay (SPDT) to enable the analog signal from the TempTrac to the VFD to regulate the speed of the blower.

a. The TempTrac will continue to monitor the stored water temperature in the tank.

b. When the setpoint temperature is reached the call-for-heat signal to the flame safeguard control is

discontinued.

c. The flame safeguard control deenergizes the VFD blower system and the gas valve, thereby suspending

burner operation.

d. As heat is transferred to the building, the water heater loop temperature will fall below the set point. The

TempTrac will sense this condition and begin the call-for-heat sequence again.

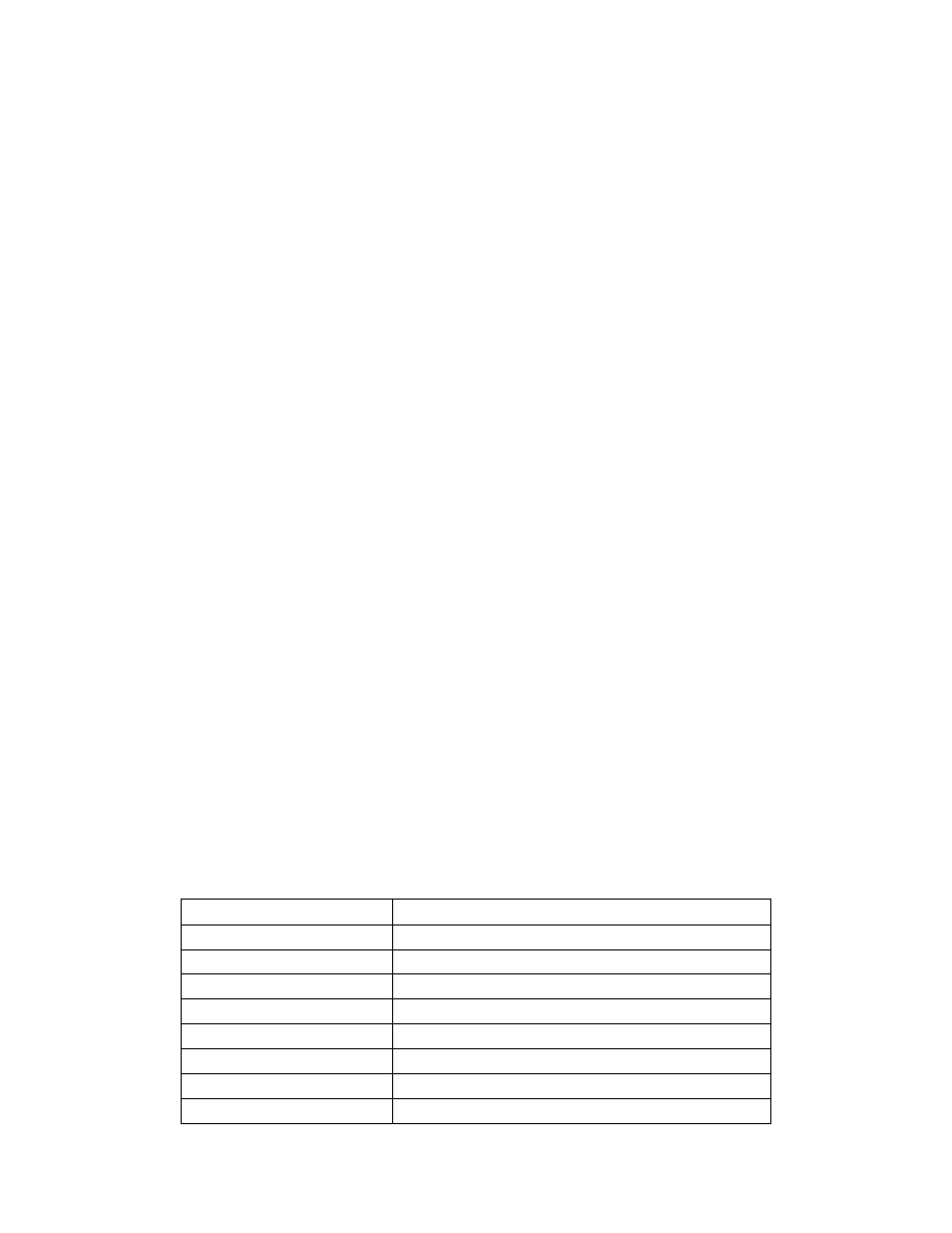

9. Flame Safeguard LED Diagnostic Indicator

- If the Fenwal Flame Safeguard Control at any time during the

operating sequence senses an improper operating state and locks out, the diagnostic red LED located on the

control board will flash to indicate one of the following conditions exist:

LED INDICATION

FAULT MODE

On

Normal Operation

OFF

Internal Control Failure – check power

1 Flash

Airflow Fault

2 Flashes

Erroneous Flame Signal

3 Flashes

Ignition Lockout

4 Flashes

Hot Surface Igniter Fault

5 Flashes

Low Voltage (24 VAC)

6 Flashes

Valve Relay Problem