0 annual servicing – Baxi Potterton BBU 15 HE User Manual

Page 28

28

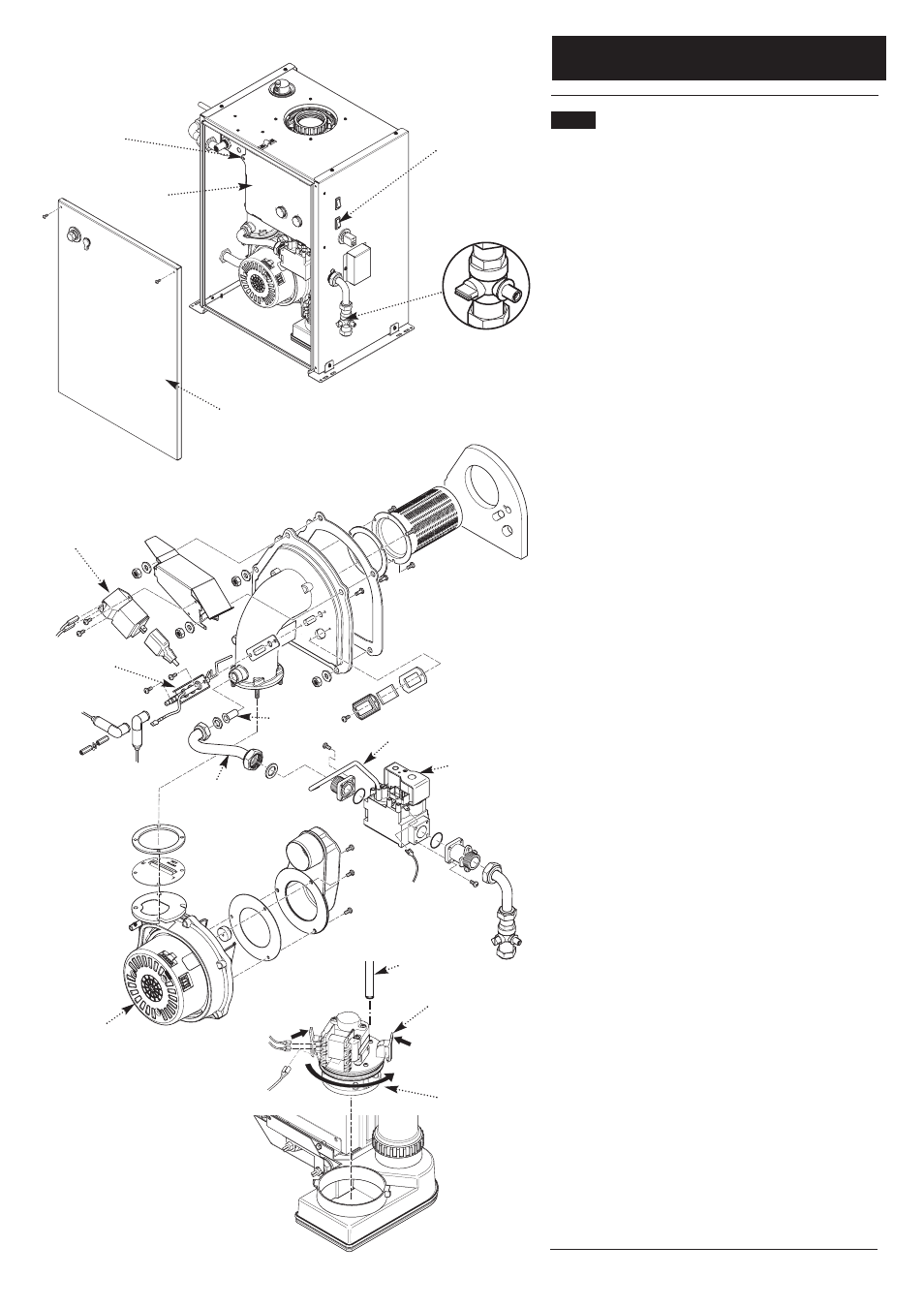

© Baxi Heating UK Ltd 2009

9.0 Annual Servicing

9.2

Annual Servicing - Inspection

1. Ensure that the boiler is cool.

2. Ensure that the gas supply to the boiler is isolated.

3. Operate the Reset switch (Fig. 41) to activate the

condensate pump and then repeat. This will empty most of

the condensate from the sump.9. Isolate the boiler from the

electrical supply.

4. Undo & remove the flue sampling plug and washer. Remove

the screws retaining the boiler front panel, and lift the panel

away (Fig. 43).

5. Remove the screw securing the PCB control box and swing

the box to the right (Fig. 43).

6. Disconnect the two plugs from the fan motor and remove

the sensing pipe from between the gas valve and fan outlet.

7. Remove the gas feed pipe and washers, and extract the

injector from the gas/air inlet manifold.

8. For ease of access disconnect the following:-

a) 2 pin plug on NTC lead

b) all wires from electrode assembly

c) all wires from spark generator

d) both wires from the overheat thermostat

e) the red and black wires connected together

9. Undo the two securing nuts and remove the spark

generator and bracket.

10. Undo the combustion panel securing nuts and remove the

special spring washers. Remove the complete fan & panel

assembly from the boiler.

11. Lay the assembly to one side. The outer insulation panel is

fitted to the rear of the combustion box panel.

12. Clean inside the heat exchanger and examine the

condition of the fins.

13. Examine the burner, electrodes, insulation and seal,

replacing if necessary. Also check the condition of the three

insulation pieces in the rear of the heat exchanger.

14. Disconnect the wires on the condensate pump motor and

pull off the plastic discharge pipe. Cut and remove the transit

cable tie. It is not necessary to replace this item.

15. Squeeze the two retaining clips and turn the pump

anticlockwise to remove it. Draw it upwards from the sump.

16. Clean any debris from the sump and examine the

condition of the pump seal, replacing if necessary.

17. Reassemble in reverse order of dismantling, checking and

replacing any components as necessary. Recommission the

boiler and complete the relevant Service Interval Record

section of the Benchmark Commissioning Checklist at the rear

of this publication.

Fig. 43

PCB Control

Box

PCB Control Box

Securing Screw

Locking Clip

Condensate Pump

Discharge Pipe

Fig. 44

Boiler Front

Panel

Spark

Generator

Electrode

Assembly

Injector

Sensing Pipe

Gas Valve

Gas Feed

Pipe

Fan

Reset Switch

Off Position