Gsm/dcs/pcs power amplifier cgy2014tt – Philips CGY2014TT User Manual

Page 12

2000 Oct 16

12

Philips Semiconductors

Product specification

GSM/DCS/PCS power amplifier

CGY2014TT

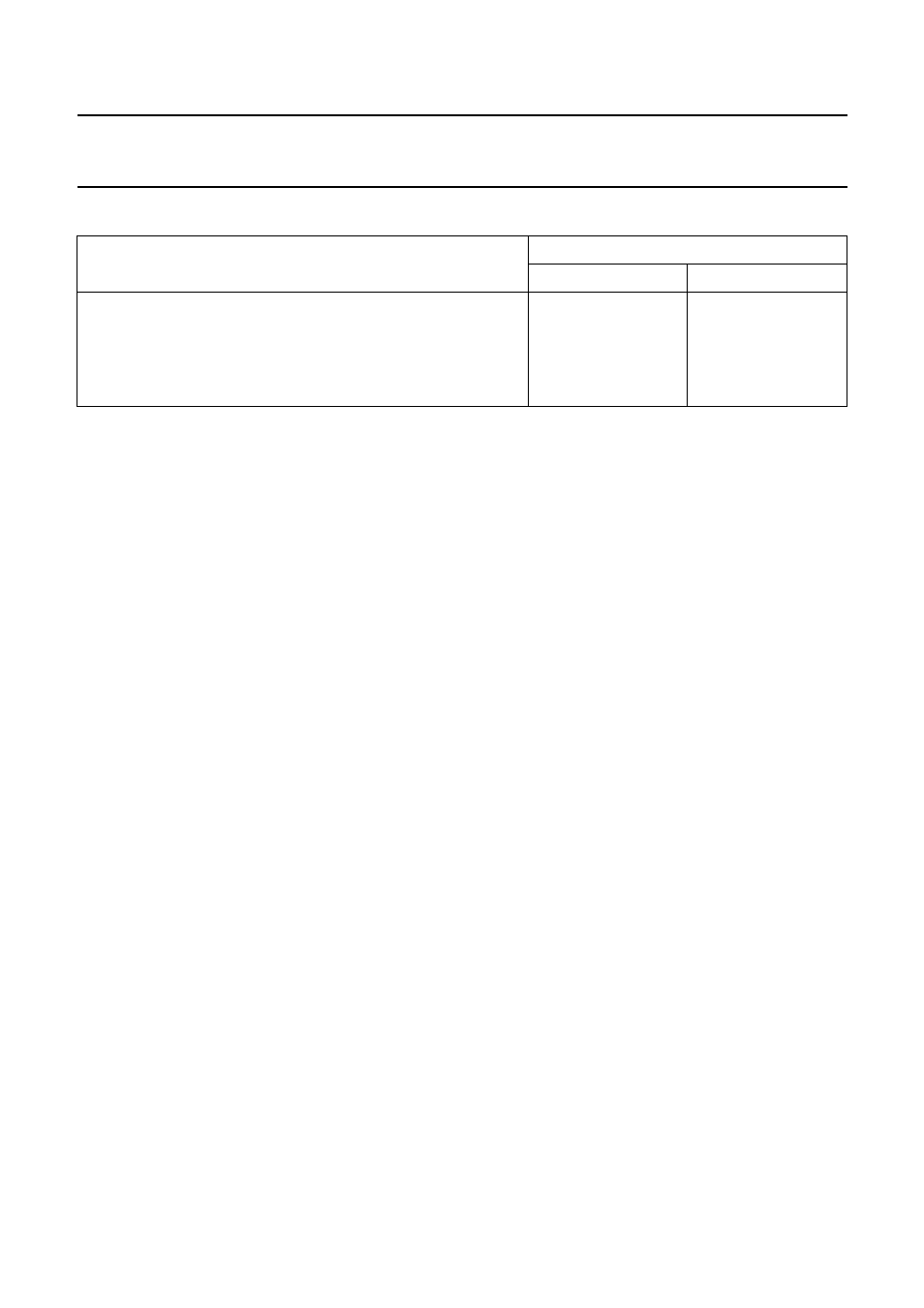

Suitability of surface mount IC packages for wave and reflow soldering methods

Notes

1. All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the maximum

temperature (with respect to time) and body size of the package, there is a risk that internal or external package

cracks may occur due to vaporization of the moisture in them (the so called popcorn effect). For details, refer to the

Drypack information in the

“Data Handbook IC26; Integrated Circuit Packages; Section: Packing Methods”.

2. These packages are not suitable for wave soldering as a solder joint between the printed-circuit board and heatsink

(at bottom version) can not be achieved, and as solder may stick to the heatsink (on top version).

3. If wave soldering is considered, then the package must be placed at a 45

°

angle to the solder wave direction.

The package footprint must incorporate solder thieves downstream and at the side corners.

4. Wave soldering is only suitable for LQFP, TQFP and QFP packages with a pitch (e) equal to or larger than 0.8 mm;

it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

5. Wave soldering is only suitable for SSOP and TSSOP packages with a pitch (e) equal to or larger than 0.65 mm; it is

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

PACKAGE

SOLDERING METHOD

WAVE

REFLOW

(1)

BGA, LFBGA, SQFP, TFBGA

not suitable

suitable

HBCC, HLQFP, HSQFP, HSOP, HTQFP, HTSSOP, SMS

not suitable

(2)

suitable

PLCC

(3)

, SO, SOJ

suitable

suitable

LQFP, QFP, TQFP

not recommended

(3)(4)

suitable

SSOP, TSSOP, VSO

not recommended

(5)

suitable