0 error codes – Baxi Potterton ECOGEN 24/1.0 User Manual

Page 19

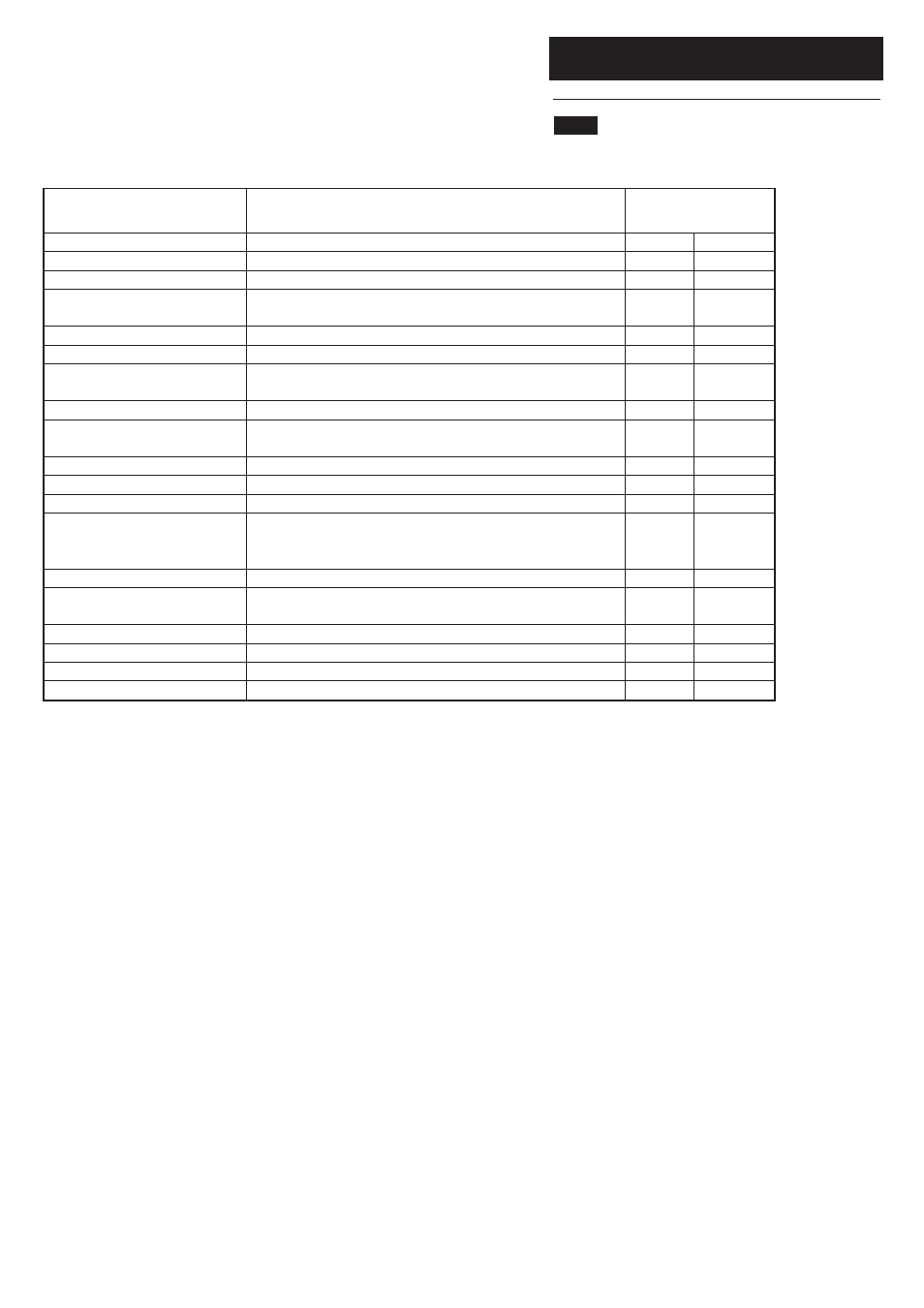

11.0 Error Codes

19

© Baxi Heating UK Ltd 2010

Error code: Display

Description

Lockout/reset action

Eng

Sup

280 : Engine dome overtemp

Engine dome overtemp has operated

AR

282: G83/ENS/G1M

G83/ENS module has detected an unhealthy mains condition

AR

285: Alternator Short

Power monitor IC has detected a short-circuit condition

AR

287: Eng head under temp

Engine head temperature thermocouple measurement below

103 degrees C when the CX relay is energised

AR

298: False flame engine

Ionisation probe of engine burner detected false flame

AR

299: False flame supplementary

Ionisation probe of supplementary burner detected false flame

AR

300: Eng head under temp

Engine head control temperature less than 150 degrees C when

CX relay is energised

UR

301: Eng head over temp

Engine head control temperature greater than 540 degrees C

AR

302: Eng head thermocouple

Magnitude of the difference between the engine head control

and limit thermocouples is greater than 100 degrees C

UR

303: Control thermocouple

Engine head control thermocouple failure

UR

304: Limit thermocouple

Engine head limit thermocouple failure

UR

309: Power fail detection

Power failure to fan detected 24v dc supply

AR

310: Power monitor comm.

No data received from the power meter IC in the last 10 seconds

or the power monitor failed to register with the EGC

microcontroller within 10 seconds of power up

AR

311: EGC comm. failure

Communication timeout or communication failure

AR

421: Eng bu exc temp diff h’ex

Engine burner excessive temperature difference across the

heat exchanger

AR

422: BCU Eng bu inconsistent

Transmitted state of the engine burner BCU isn’t consistent

AR

423: BCU Supp bu inconsistent

Transmitted state of the supplementary burner BCU isn’t consistent

AR

424: Rep. loss of flame Eng bu

Repeated loss of flame engine burner

UR

425: Rep. loss of flame Supp bu

repeated loss of flame supplementary burner

UR

11.1

List of Error Codes (cont)

This is a shortened list of the error codes, which will be displayed on the Programmer or on the room unit. If more than one error is active, the one with the

higher priority or the one that appeared first will be displayed.

Error codes 157,274,261,262 and 300 can be reset by the user by pressing the user reset button for 2 seconds, turning the dial to alter the flashing NO to a YES

and then pressing the OK button. After a few seconds the error should clear enabling a restart of the appliance. Errors 261 and 262 may indicate a problem with

the gas supply.

Errors 157,164,274 and 300 may indicate a problem with the central heating water fill or pump. If the problem persists contact the installer with the error code.

Error 158 indicates a possible blockage in the condense drain.

Error codes 10 through to 99 (except 97) are linked to installation and commissioning of your system and as such you should contact your installer to complete

commissioning.

Error codes that are shown as automatic reset will disappear once the fault has cleared. The appliance will restart if there is a demand except in the case of

errors 263 and 264 when the appliance must be switched off and on again to enable a restart.

All other error codes indicate a fault condition, which will require the attention of a service engineer.

UR = User Reset, AR = Automatic Reset, ARP = Automatic Reset after Power Down

NOTE: An automatic reset is only done if the fault condition has cleared.