K formula – Lennox Hearth GRANDVIEW GV230 User Manual

Page 8

8

When the Grandview™ 230 is installed in an Alcove, the floor protection

must be a thermally rated non-combustible floor protector meeting or

exceeding a thermal rating of k=.47 or equivalent with a listed thickness

of 1/2" (12.7 mm) minimum in the USA and Canada. The thermal protec-

tion must extend 16” in front of the heater and 8” to each side (measured

from the door opening).

Using Alternate Material As Floor Protection

The floor protection or alternate material used as a floor protector must

be constructed of a durable noncombustible material having an equal or

better thermal conductivity value (lower k value) of k =.47 BTU/IN FT2 HR

°F or a thermal resistance that equals or exceeds r = 2.13 HR °F FT2 IN/

BTU with a minimum thickness of 1/2”. With these values, determine the

minimum thickness of the alternate material required using the formula(s)

and shown in Table 1.

Note: Any noncombustible material having a minimum thickness of

1/2”(12.7mm) whose k value is less than .47 or whose r value is more

than 2.13 is acceptable. If the alternate material used has a higher k value

or lower r value will require a greater thickness of the material used. In

some cases, if the k value is less or the r value higher, a thinner material

may be used.

Methods of determining floor protection equivalents:

To determine the thickness required for the alternate material when

either the "k" value or "r" value is known, use either the k formula or r

formula.

Example: If Micore 160 Mineral Fiber Board is to be used for the

floor protection, how thick must this material be?

k

M

= k value per inch of alternate material

r

M

= r value per inch of alternate material

T

M

= minimum thickness required for alternate material

T

S

= standard thickness of the alternate material

k

L

= k value per inch of listed material

r

L

= r value per inch of listed material

T

L

= minimum thickness of listed material

Note: An asterisk "*" indicates, it is a value taken from Table 1.

Using the k formula:

k formula:

Minimum

k-value (per Inch) of

Specified min.

thickness of = alternate material (k

M

) x

thickness

alternate

k-value (per inch)

of listed

material (T

M

)

of listed material (k

L

)

material (T

L

)

T

M

(inches) =

k

M

x

T

L

*.47

T

M

(inches) = *.35

x

.50"

*.47

.312 (inches)=

.745

x

.50"

Answer - The minimum required thickness of the Micore 160 is .372"

therefore round up to nearest standard thickness available which is

3/8” (.375”)

Minimum

r-value (per Inch)

Specified min.

thickness of = of listed material

x

thickness

alternate

r-value (per inch)

of listed

material

of alternate material

material

T

M

(inches) =

r

L

x

T

L

r

M

T

M

(inches) = *2.13 x

.50"

*2.86

.312 (inches)=

.745

x

.50"

Answer - The minimum required thickness of the Micore 160 is .372"

therefore round up to nearest standard thickness available which is

3/8” (.375”)

Using the r formula:

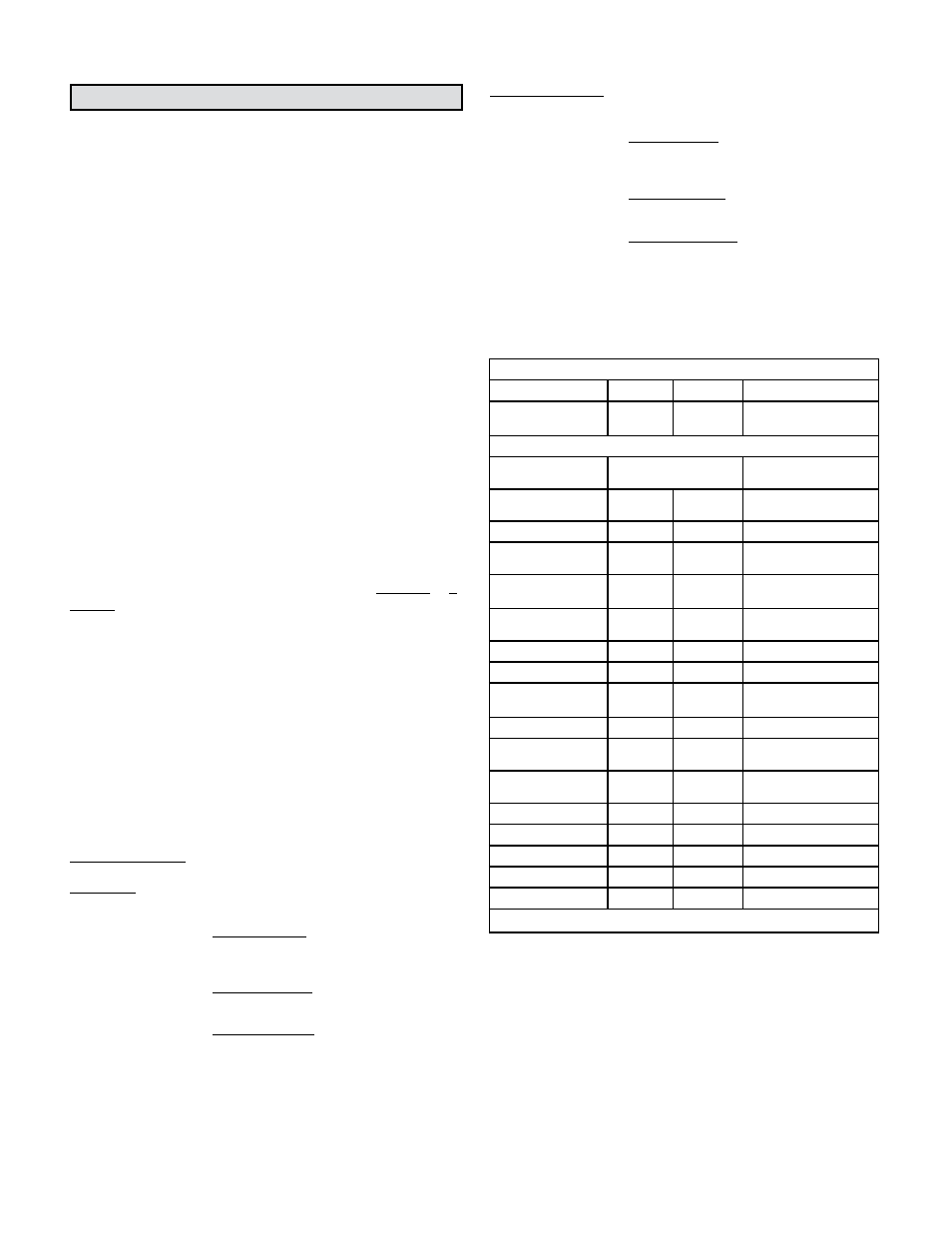

Listed Material

k (per inch)

r (per inch)

Listed Min. Thickness

Listed Material

.47

K

L

2.13

r

L

1/2

"

(.50")

T

L

** Approved Alternate Materials for Floor/Hearth Protection

Alternative Materials

Thermal Values

Minimum Thickness

(rounded to nearest 1/8 inch)

k (per inch)

K

M

r (per inch)

r

M

Min. Thickness

T

M

Kaowool M Board

.47

2.13

.5" (1/2")

Micore 160™

U.S. Gypsum

.35

2.86

.37" (3/8")

Micore 300™

U.S. Gypsum

.46

2.17

.49" (1/2")

Durock™ Cement Board

U.S. Gypsum

1.92

.52

2.04" (2-1/8")

Hardibacker™

1.95

.51

2.07" (2-1/8")

Hardibacker 500™

2.30

.43

2.45" (2-1/2")

Cultured Stone Hearth-

stone™

2.82

.35

3" (3")

Wonderboard

3.23

.31

3.44" (3-1/2")

Super Firetemp M

Johns-Manville

.61

1.64

.65" (3/4")

Super Firetemp L

Johns-Manville

.54

1.85

.57" (5/8")

Face brick

9.00

.111

9.57" (9-5/8")

Common brick

5.00

.20

5.32” (5-3/8")

Cement mortar

5.00

.20

5.32” (5-3/8”)

Ceramic tile

12.5

.08

13.30" (13-3/8")

Marble

~11

~.09

11.70" (11-3/4")

Table 1 - USA AND CANADA REQUIREMENTS

** If the hearth extension material(s) that is intended to be used is NOT

listed on Table 1, the material can still be used if the material(s) is non-

combustible. However, the manufacturer of the material must provide

either the listed k-value per inch or r-value per inch with listed thickness

so that the minimum thickness required for the hearth can be calculated

(per instructions here or as specified in the NFI Certification Manuals).

Note: Also see NFI (National Fireplace Institute) Certification Manuals show-

ing other acceptable calculation methods and acceptable alternate materials

which can be used.

ALCOVE INSTALLATIONS - FLOOR PROTECTION