Figure 9 – Lennox Hearth GRANDVIEW GV230 User Manual

Page 12

12

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

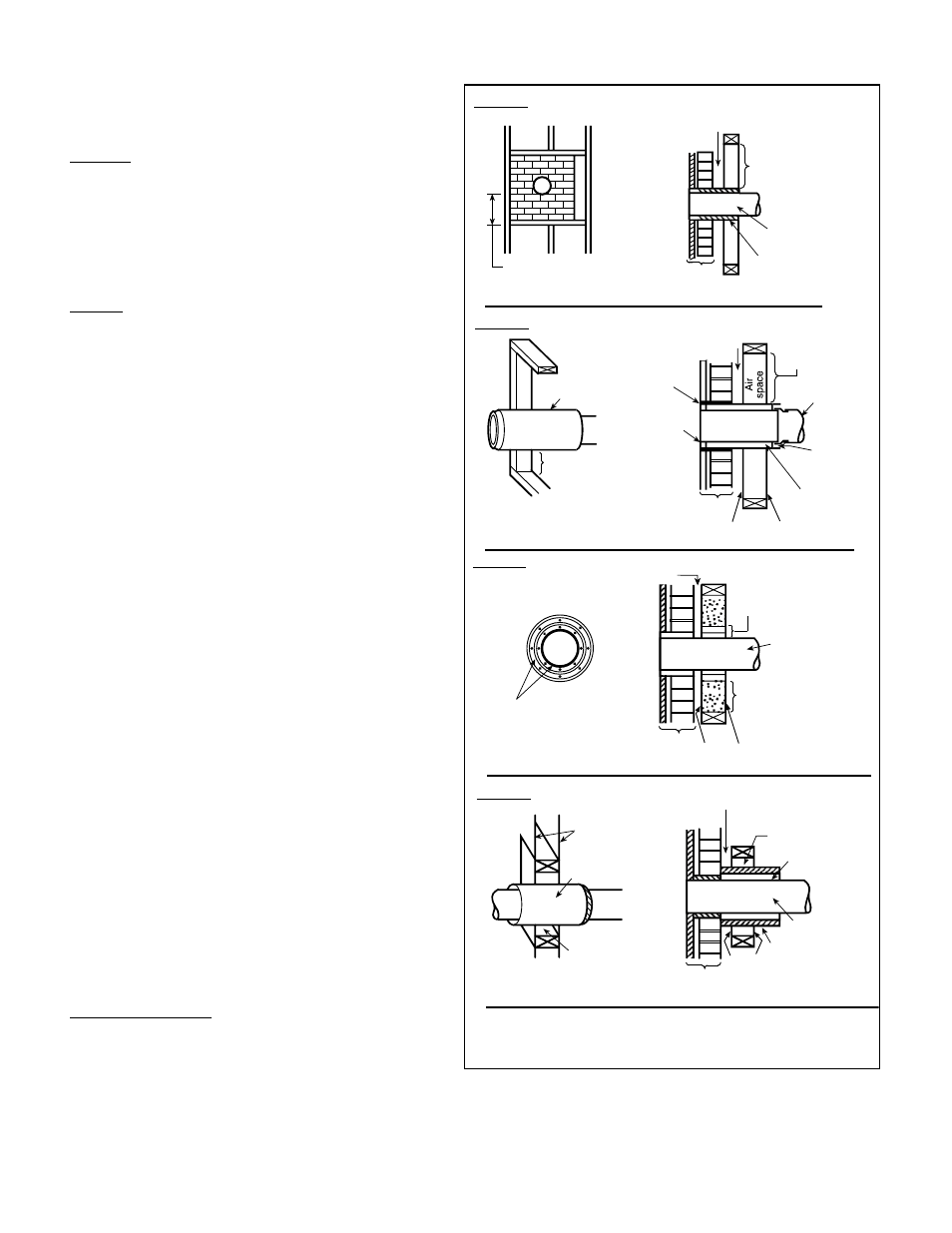

Chimney Connector Systems and Clearances from Combustible

Walls for Residential Heating Appliances (NFPA 211) Refer to

Figure 9

System A. Minimum 3.5 in. (90 mm) thick brick masonry wall

framed into combustible wall with a minimum of 12 in. (305 mm)

brick separation from clay liner to combustibles. Fireclay liner (ASTM

C 315, Standard Specification for Clay Flue Linings, or equivalent),

minimum 5/8 in. (16 mm) wall thickness, shall run from outer surface

of brick wall to, but not beyond, the inner surface of chimney flue

liner and shall be firmly cemented in place.

Clearance: 12 in. (305 mm)

System B. Solid-insulated, listed factory-built chimney length of the

same inside diameter as the chimney connector and having 1 in.

(25.4 mm) or more of insulation with a minimum 9 in. (229 mm) air

space between the outer wall of the chimney length and combustibles.

The inner end of the chimney length shall be flush with the inside of

the masonry chimney flue and shall be sealed to the flue and to the

brick masonry penetration with non-water-soluble refractory cement.

Supports shall be securely fastened to wall surfaces on all sides.

Fasteners between supports and the chimney length shall not pen-

etrate the chimney liner.

Clearance: 9 in. (229 mm)

System C. Sheet steel chimney connector, minimum 24 gauge [0.024

in. (0.61 mm)] in thickness, with a ventilated thimble, minimum 24

gauge [0.024 in. (0.61 mm)] in thickness, having two 1 in. (25.4

mm) air channels, separated from combustibles by a minimum of 6

in. (152 mm) of glass fiber insulation. Opening shall be covered, and

thimble supported with a sheet steel support, minimum 24 gauge

[0.024 in. (0.61 mm)] in thickness.

Supports shall be securely fastened to wall surfaces on all sides and

shall be sized to fit and hold chimney section. Fasteners used to secure

chimney section shall not penetrate chimney flue liner.

Clearance: 6 in. (152 mm)

System D. Solid-insulated, listed factory-built chimney length with

an inside diameter 2 in. (51 mm) larger than the chimney connector

and having 1 in. (25.4 mm) or more of insulation, serving as a pass-

through for a single wall sheet steel chimney connector of minimum

24 gauge [0.024 in. (0.61 mm)] thickness, with a minimum 2 in.

(51 mm) air space between the outer wall of chimney section and

combustibles. Minimum length of chimney section shall be 12 in.

(305 mm). Chimney section concentric with and spaced 1 in. (25.4

mm) away from connector by means of sheet steel support plates

on both ends of chimney section. Opening shall be covered, and

chimney section supported on both sides with sheet steel supports

of minimum 24 gauge [0.024 in. (0.61 mm)] thickness.

Supports shall be securely fastened to wall surfaces on all sides and

shall be sized to fit and hold chimney section. Fasteners used to secure

chimney section shall not penetrate chimney flue liner.

Clearance: 2 in. (51 mm)

Additional requirements:

1. Insulation material used as part of wall pass-through system shall be

of noncombustible material and shall have a thermal conductivity of

1.0 Btu-in./hr-ft

2

- ºF (4.88 kg-cal/hr-m

2

- ºC) or less.

2. All clearances and thicknesses are minimums; larger clearances and

thicknesses shall be permitted.

3. Any material used to close up an opening for the connector shall be of

noncombustible material.

4. A connector to a masonry chimney, except for System B, shall extend

in one continuous piece through the wall pass-through system and the

chimney wall to the inner face of the flue liner, but not beyond.

Factory Built

Chimney Length

Air Space – 9 in.

(228.6mm) Min.

Chimney Length

Flush with

Inside of Flue

Min. Clearance

9 in. (229mm)

Chimney

Connector

Use Chimney

Mfrs. Parts to

Attach

Connector

Solid-Insulated

Listed Factory-

Built Chimney

Length

Sheet Steel Supports

Sheet Steel Supports

Sheet Steel Supports

Minimum Chimney Clearance from Masonry to Sheet Steel

Supports & Combustibles – 2 in. (51mm)

Nonsoluble

Refractory

Cement

Minimum chimney clearance to sheet

steel supportrs and combustibles

2 in. (51mm)

Chimney

Connector

2 Air Channels, Each 1

in. (25.4 mm)

2 Ventilated Air

Channels, Each

1 in. (25.4 mm)

Construction of

Sheet Steel

Minimum chimney clearance to sheet steel

supports and combustibles 2 in. (51mm)

Sheet Steel

Supports

Chimney

Connector

Chimney

Section

Air Space – 2 in.

(51mm) Min.

Chimney connector

Chimney length

1 in. (25.4 mm)

air space to

chimney length

Min. Clearance

2 in. (51 mm)

Minimum

12 in. (305mm)

to combustibles

Masonry chimney

constructed to NFPA 211

Masonry chimney

constructed to NFPA 211

Masonry chimney

constructed to NFPA 211

Masonry chimney

constructed to NFPA 211

Minimum chimney clearance to brick

and combustibles 2 in. (51mm)

Minimum clearance

12 in. (305mm)

of brick

Chimney

Chimney

flue

Chimney

flue

Chimney

flue

connector

Fire clay

liner

Figure 9 -

Chimney Connector Systems and Clearances from Combustible Walls

System A

System B

System C

System D