Troubleshooting – Lochinvar EnergyRite ER402 User Manual

Page 29

Service Manual

29

3

Troubleshooting

(continued)

16. The gas valve will open at the end of the trial for

ignition stage and remain open as the burners fire.

Observe the gas manifold pressure when valves open.

If insufficient gas pressure is supplied to the burners,

the burners will not fire. Record the gas pressure

indicated on the manometer or magnahelic. Subtract

the air pressure in the front chamber (as recorded in

Step 7) from the gross manifold pressure observed at

the end of trial for ignition and when the burners are

firing. The gross manifold pressure will typically be

within the range of 3.0" w.c. to 3.5" w.c. for Natural Gas

and 5.8" w.c. to 6.3" w.c. for LP Gas at full fire. The

difference in the gross manifold pressure and the front

chamber pressure is the net manifold pressure setting

of the gas valve’s regulator. Compare the net setting to

the setting specified for the type of gas used. Adjust

regulator as required. Set the thermostat to a setting

lower than the appliance’s water temperature to turn

the burners off. Allow appliance to run through the

post purge sequence. Turn the power switch to the

“OFF” position.

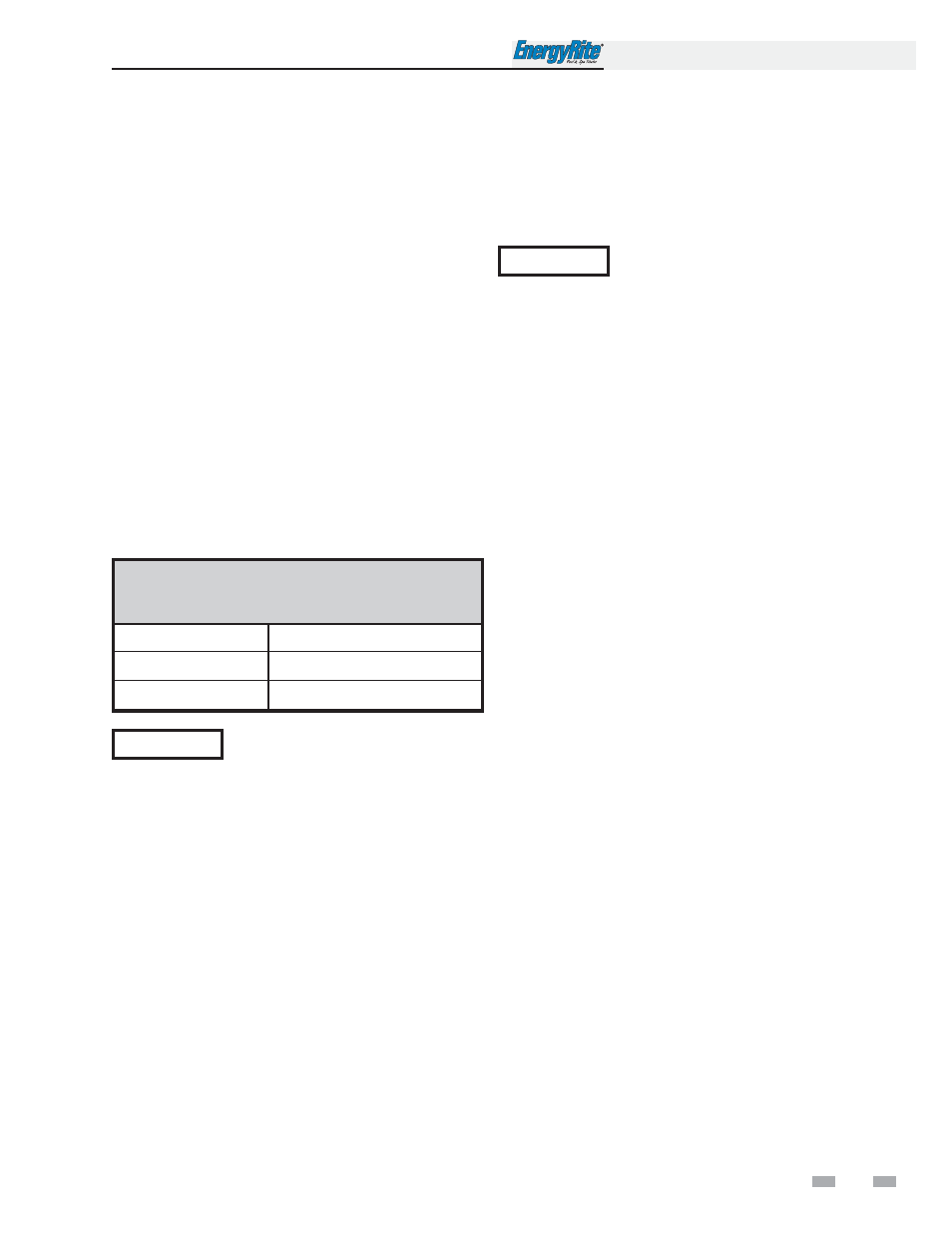

TABLE - 3E

NET MANIFOLD PRESSURE

Regulator Pressure Less Front Chamber Pressure

Type of Gas

Net Manifold Pressure Setting

Natural Gas

1.8" w.c.

LP Gas

4.6" w.c.

NOTICE

The front chamber pressure must be

subtracted from the gross regulator

pressure to obtain actual net manifold

pressure for normal operation. The front

chamber pressure may vary based on

elevation, stages of operation, vent

length and model. For information on

chamber pressure, see the Maintenance

section for Combustion Air Shutter

Adjustment in this manual.

19. Replace the cover screw on the regulator and turn the

power switch to the “ON” position. Set the thermostat to

call for heat. Observe gas regulator pressure again at the

burner “ON” stages.

Repeat this sequence until the

proper regulator setting has been obtained.

NOTICE

If the regulator cover screw is not in place

and tight, the appliance will not function

properly.

20. Turn the power switch to the “OFF” position.

21. Turn the gas valves and the manual gas cock knob to the

“OFF” position.

22. Remove the gas pressure fitting from the gas valve and

replace with the 1/8" hex plug (removed in Step 10) and

tighten.

23. Ensure that the chamber pressure reference hose is properly

connected to the gas valve.

24. Turn the gas valve knobs to the “ON” position.

25. Turn the power switch to the “ON” position and replace the

jacket panel. The appliance is now ready to operate.

If manifold pressure cannot be properly maintained, check the

gas supply pressure with a manometer connected to the inlet

pressure tap on the gas control.

17. If adjustment is necessary, remove the regulator cover

screw on the gas valve (FIG. 3-2).

18. Turn the regulator adjustment screw clockwise to raise

regulator gas pressure, counterclockwise to lower the

regulator gas pressure. Turn the regulator adjustment

screw a 1/4 turn in the desired rotation and cycle the

burners on in the sequence listed in this section and

record the observed chamber and regulator settings.

Subtract to determine the net manifold pressure

setting. Repeat as necessary to achieve the specified net

manifold pressure setting.