Land Pride RC5515 User Manual

Page 47

45

Section 5: Maintenance & Lubrication

5/29/13

RC5515 & RC6515 (540 RPM) RCM5515 & RCM6515 (1000 RPM) Rotary Cutter 318-721M

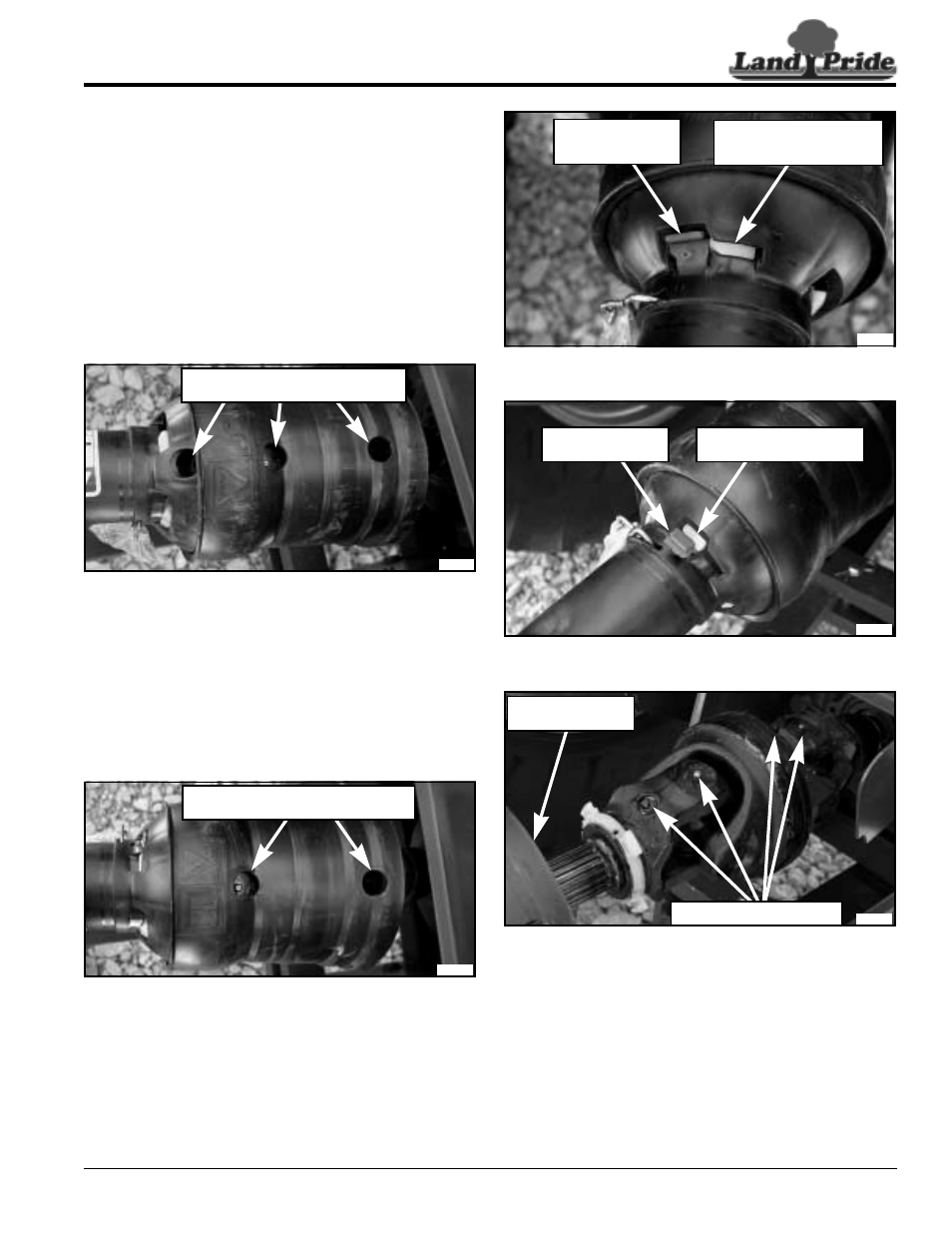

Accessing CV Driveline Joints

Refer to Figure 5-13 on page 44:

There are two ways the constant velocity driveline joints

shown in Figure 5-1 can be accessed for lubrication. One

is through holes in the driveline shield and the other is to

slide the shields back to expose the grease zerks.

Lubrication Through Access Holes

1.

Refer to Figure 5-15: Rotate driveline shield until

holes in shield align with grease zerks in CV joint.

2.

Apply proper amount and type of lubrication. Refer to

“CV Main Driveline Joints & Shields” on page 44

for quantities and type of lubrication.

Lubrication Through Three Holes In Driveline Shield

Figure 5-15

3.

Refer to Figure 5-16: Rotate driveline shield 180

o

until holes on opposite side of shield aligns with

remaining grease zerks in CV joint.

4.

Repeat step 2 above on any grease zerks that were

not greased in step 2.

5.

Steps 1 thru 2 can be repeated to lubricate universal

joint on opposite end of driveline. (Opposite end of

driveline has only one grease zerk.)

Lubrication Through Two Holes In Driveline Shield

Figure 5-16

Lubrication By Sliding Driveline Shields Back

1.

Refer to Figure 5-17: With a flat bladed screwdriver

or similar tool, pry top of red locking tab up.

2.

Refer to Figure 5-18: Rotate white locking ring fully

counterclockwise to the position shown.

3.

Refer to Figure 5-19: Pull back on driveline shielding

until CV joint is exposed.

Rotate Driveline Shield to Align

3-Holes in Shield With Grease Zerks

33992

33993

Rotate Driveline Shield to Align

2-Holes in Shield With Grease Zerks

Locked Driveline Shield

Figure 5-17

Unlocked Driveline Shield

Figure 5-18

Slide Driveline Shield Back To Expose Grease Zerks

Figure 5-19

4.

Apply proper amount and type of lubrication. Refer to

“CV Main Driveline Joints & Shields” on page 44

for quantities and type of lubrication.

5.

Slide driveline shield back to its operating position.

6.

Refer to Figure 5-17: Rotate white locking ring

clockwise and press locking tab down until it snaps in

place as shown.

7.

Steps 1 thru 6 can be repeated to lubricate universal

joint on opposite end of driveline.

Red Locking Tab

Snapped Down

Into Position

White Locking Ring

Positioned On Right Side

of Red Locking Tab

33994

Red Locking Tab

Pried Up

White Locking Ring

Rotated Counterclockwise

33995

Driveline Shield

Pulled Back

Exposed CV Grease Zerks

33996