Operation, Gmaw fcaw smaw crisp smaw soft gtaw, V300-pro – Lincoln Electric INVERTEC V300-PRO SVM105-B User Manual

Page 15

V300-PRO

OPERATION

B-3

B-3

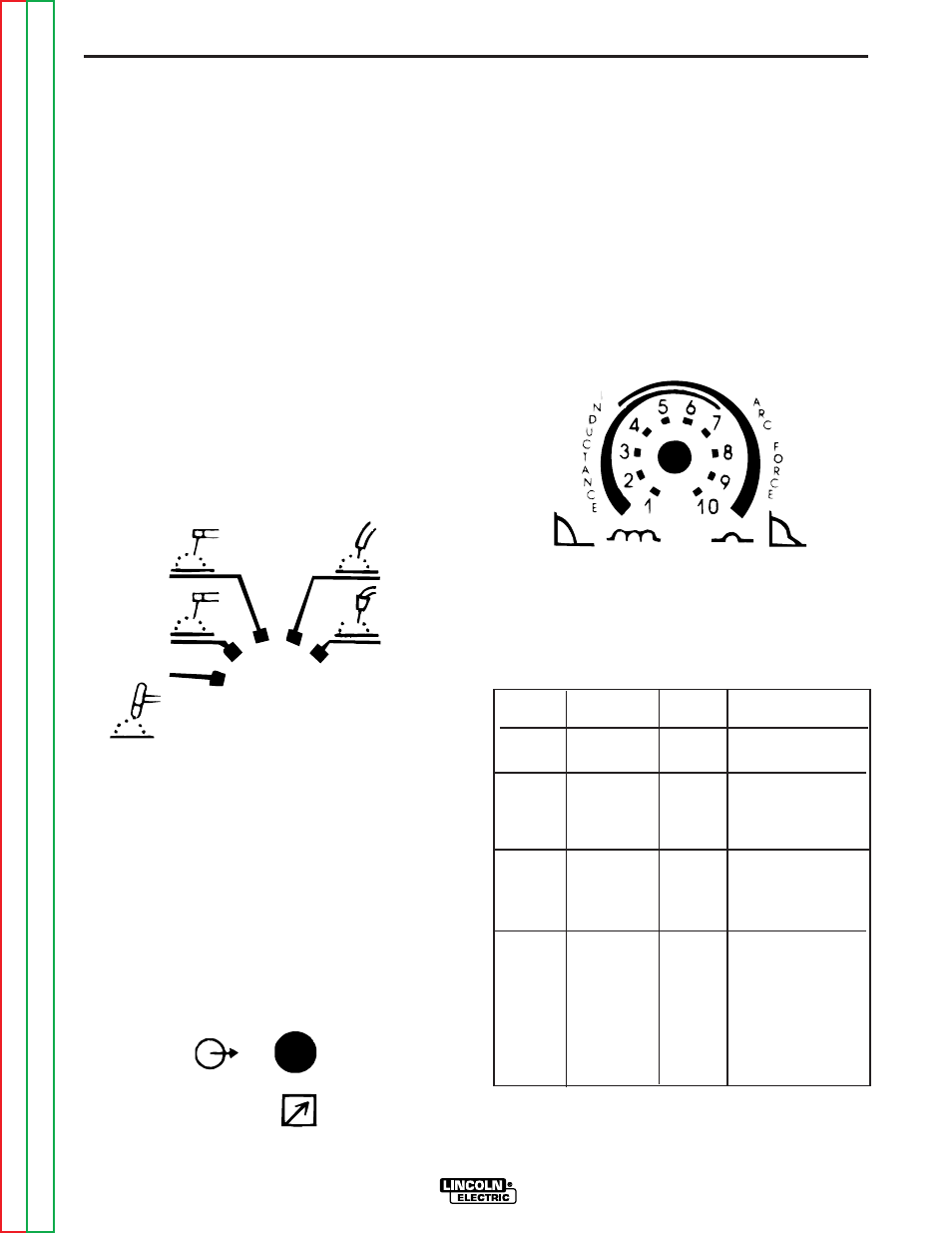

MODE SWITCH

GTAW

Optimized for both scratch start and Hi-

Freq kit use.

CC SOFT

Best for EXX18 thru EXX28 stick elec-

trodes.

CC Crisp

Use this mode for stick welding with

EXX10 thru EXX14 electrodes. Non-

welding applications such as resistive

heating or output tests with resistive

loads should be done in this mode with

Arc Force Control set to minimum.

CV FCAW

This setting has been optimized for

Innershield

®

and Outershield

®

flux-cored

electrodes.

CV GMAW

Short circuit, glob and spray transfer

solid wire and gas welding are done in

this mode. Low end procedures, less

than 16V, may operate better in the

FCAW mode.

OUTPUT TERMINALS SWITCH

For processes and equipment that require energized

machine terminals (stick, TIG, air-carbon arc cutting or

hot tip LN-25), set the Output Terminals Switch to “ON”

position.

Set to the REMOTE (OFF) position when using LN-25

with K431/K432 or K624-1 options or other wirefeeders

which allow the gun trigger to energize the welding ter-

minals.

ARC FORCE/INDUCTANCE CONTROL

This control functions in all modes except GTAW. For

CC modes, this control acts as an Arc Force adjust-

ment. The arc is soft at the minimum settings and more

forceful or driving at the maximum settings. Higher

spatter levels may be present at the maximum set-

tings.

For CV modes, this control will set the degree of “pinch

effect” which predominantly affects short circuit trans-

fer. In FCAW, the maximum setting is generally pre-

ferred. With GMAW, the upper half of the range is pre-

ferred with CO2 or high content CO2 mixed gas. The

lower half is for inert gas mixes.

GMAW

FCAW

SMAW

CRISP

SMAW

SOFT

GTAW

OUTPUT

TERMINALS

ON

REMOTE

Nominal

Recommended

Mode

Process

Setting

Adjustment Range

CC SMAW 1

EXX18 thru

5

1 (gentle, may stick) to 9

EXX28 stick

(forceful, more spatter)

CC SMAW 2

EXX10 thru

6

3 to 10

EXX14 stick

Air Carbon Arc

1

None

Cutting

CV FCAW

Innershield or

10

None

Outershield

Air Carbon Arc

1

None

Cutting

CV GMAW*

CO2 or 25% CO2

7.5

5 to 10

or similar

gas mixes

98% Ar-2% O2Ar,

5

1 to 10

90% He-7.5% Ar

2.5% CO2 and

other

predominantly

inert gases

RECOMMENDED SETTINGS FOR SELECTED

APPLICATIONS

Full Range Is 1-10,

1 Is Very Soft, 10 Is Very Crisp

* 1 = Lowest pinch, highest inductance and least spatter.

10 = Highest pinch, lowest inductance and most spatter.