Installation – Lincoln Electric INVERTEC V300-PRO SVM105-B User Manual

Page 10

V300-PRO

INSTALLATION

A-4

A-4

POWER INPUT CONNECTION

Connect terminal marked to earth ground per any

existing local or national electrical codes.

Single Phase Input

Connect the supply lines to the upper and lower termi-

nals of the line switch. Torque to 27.5in.-lbs.(3.0 Nm).

Do not use center terminal of the line switch.

Three Phase Input

Connect the supply lines to the line switch. Torque to

27.5in.-lbs.(3.0 Nm).

Install in accordance with all local and national electric

codes.

The V300-PRO is supplied with one cord connector to

provide strain relief for the input power cord. It is

designed for a cord diameter of .310-1.070” (7.9 -

27.2mm). The jacketed portion of the cord must go

through the connector before tightening the connector

screws.

CONNECTION OF WIRE FEEDERS TO

THE INVERTEC

LN-25 Connection Instructions

1. Turn the Invertec power switch “off”.

2. Connect the electrode cable to the output terminal

of polarity required by electrode. Connect the work

lead to the other terminal.

3. LN-25 with remote control options K431 and K432.

Use K876 adapter with K432 cable or modify K432

cable with K867 universal adapter plug. See con-

nection diagram S19899 and S19309 or S19405 in

Operator’s Mamual.

4. Place the local-remote switch in the “remote” posi-

tion if output control is desired at the wire feeder

rather than the Invertec. (LN-25 must have K431

and K432 options for remote output control opera-

tion).

LN-7 Connection Instructions (not applicable to

IEC machines with only 42V Aux.).

1. Turn the Invertec power switch “off”.

2. Connect the K480 or K1818-10 control cable from

the LN-7 to the Invertec control cable connector.

The control cable connector is located at the rear

of the Invertec.

3. Connect the electrode cable to the output terminal

of polarity required by electrode. Connect the work

lead to the other terminal.

4. Place the local-remote switch in the “local” position

to allow output control at the Invertec. (K864

remote control adapter and K857 remote control

are required for remote output control. See con-

nection diagram S19901.

5. Set the meter polarity switch on the rear of the

Invertec to coincide with wire feeder polarity used.

The wire feeder will now display the welding volt-

age.

6. If a K480 or K1818-10 is not available, see con-

nection diagram S19404 for modification of K291

or K404 LN-7 input cable with K867 universal

adapter plug..

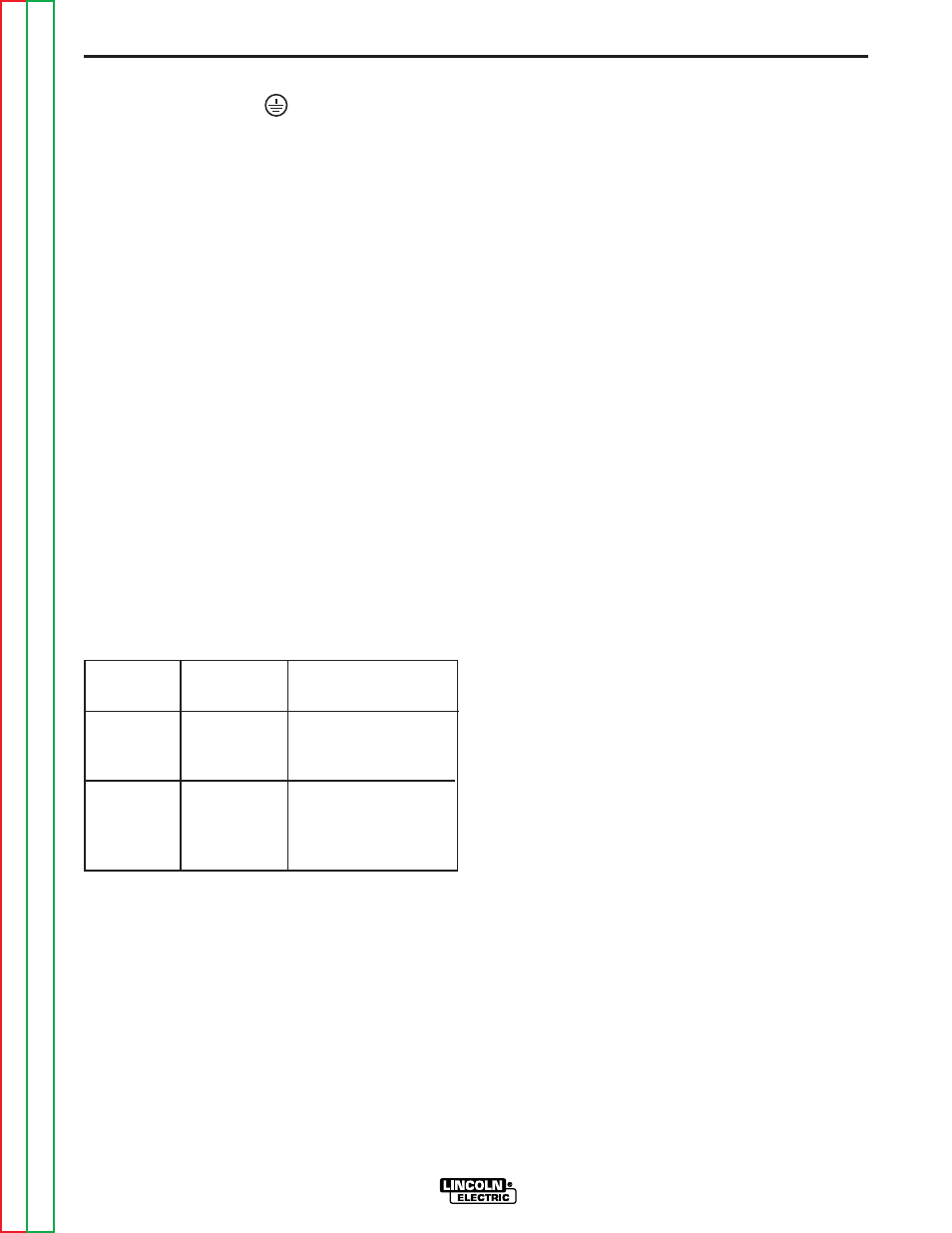

Recommended Fuse Sizes Based On The U.S.

National Electrical Code And Maximum Machine

Outputs

Fuse Size in Amps

Input Volts

(1)

(Time Delay Fuses)

208

60

3 phase

230

60

50/60 Hz

460

40

575

25

1 phase

208

85

50/60 Hz

230

80

460

50

(1)

Input voltage must be within ±10% of rated value.