Section 5: maintenance & lubrication, General maintenance information, Cutter blade maintenance – Land Pride RCM6015 User Manual

Page 26: Danger, Warning, Table of contents general maintenance information

24

Section 5: Maintenance & Lubrication

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

8/28/08

Land Pride

General Maintenance Information

Proper servicing and adjustment is the key to the long life

of any implement. With careful and systematic

inspection, you can avoid costly maintenance, time and

repair.

Check all bolts after using the unit for several hours to be

sure they are tight.

Replace any worn, damaged or illegible safety labels by

obtaining new labels from your Land Pride Dealer.

Cutter Blade Maintenance

!

DANGER!

Always disconnect main driveline from tractor PTO before

servicing the underside of the cutter deck. Cutter can be

engaged if tractor is started resulting in damage to the cutter,

bodily injury and/or death.

!

WARNING!

Always secure cutter deck in the up position with solid supports

before servicing the underside of the cutter. Never work under

equipment supported by hydraulics. Hydraulics can drop

equipment if controls are actuated or if hydraulic lines burst.

Either situation can drop the cutter instantly even when power

to the hydraulics is shut off.

1.

Always disconnect main driveline from tractor PTO

and secure cutter deck in the up position with solid

supports before servicing the underside of the cutter.

2.

Always inspect cutting blades before each use. Make

certain they are properly installed and are in good

working condition. Replace any blade that is

damaged, worn, bent, or excessively nicked. Small

nicks can be ground out when sharpening.

3.

Both blades should be sharpened at the same angle

as the original cutting edge and must be replaced or

re-ground at the same time to maintain proper

balance in the cutting unit. The following precautions

should be taken when sharpening the blades:

a. Do not remove more material than necessary.

b. Do not heat and pound out a cutting edge.

c. Do not grind blades to a razor edge. Leave a blunt

cutting edge approximately 1/16” thick.

d. Always grind the cutting edge so that the end of the

blade remains square to the cutting edge and not

rounded.

IMPORTANT: Blades must be ordered and replaced in

pairs. Order only genuine Land Pride blades. Land

Pride blades are made of special heat treated alloy

steel. Substitute blades may not meet Land Pride’s

specifications and may be dangerous to operate.

e. Do not sharpen the back side of the blade.

f. Both blades should weigh the same after

sharpening with not more than 1 oz. difference.

4.

Examine blade bolts for excessive wear and replace

if necessary. To replace blade bolts:

a. Order land Pride blade bolt part #802-277C and

lock nut #803-170C.

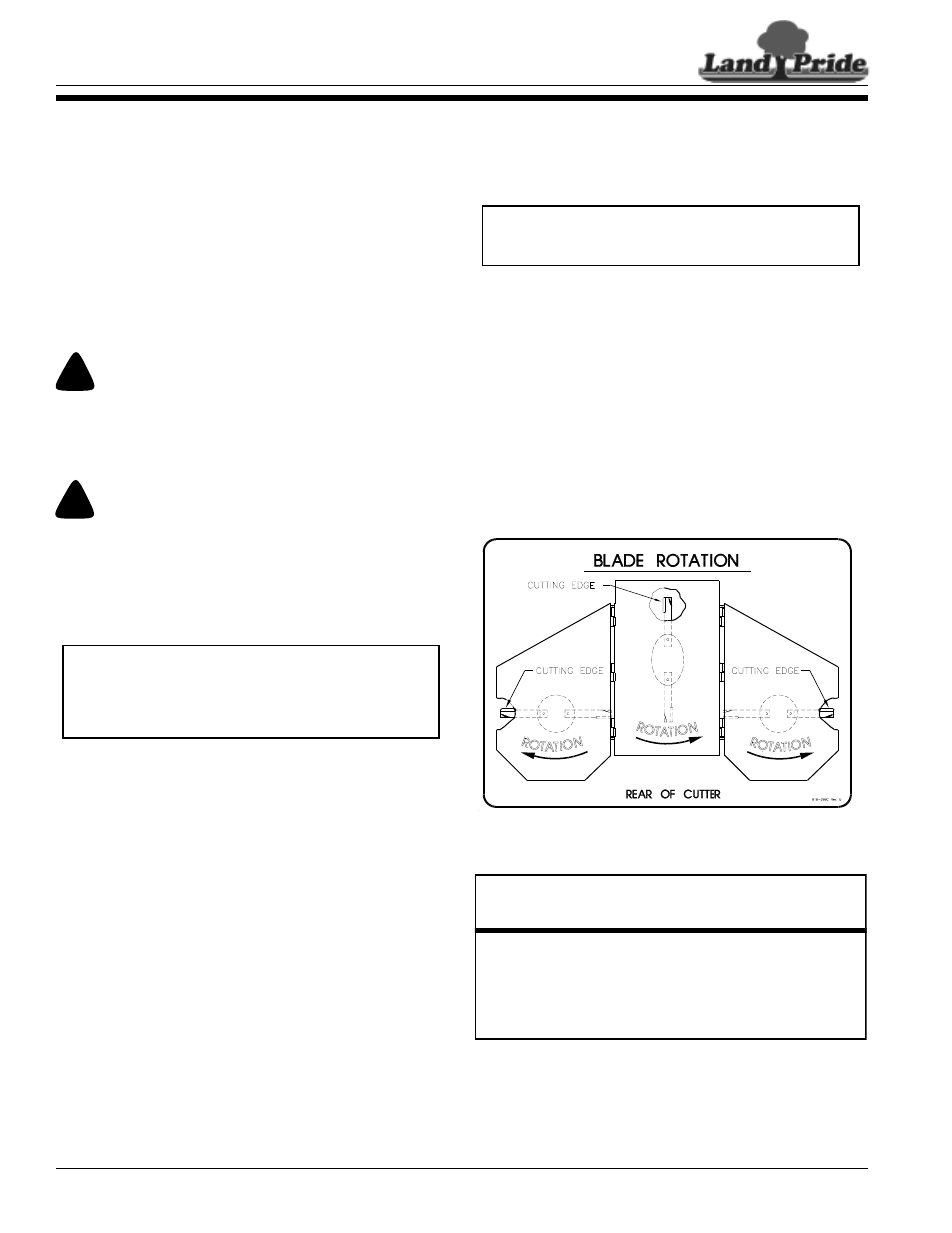

b. Refer to Figure 5-1: Carefully check the cutting

edges of the blades in relation to the blade carrier

rotation to ensure correct blade placement.

c. Torque blade lock nut to 450 ft-lbs. An extended

cheater bar may be required.

5.

If replacing dishpan, nut on gearbox output shaft

should be torqued to 550 ft-lbs. minimum and cotter

pin installed in nut with legs securely bent around

nut.

Blade Rotation

Figure 5-1

IMPORTANT: Unbalanced blades will cause

excessive vibration which can damage gear box

bearings and create structural cracks in cutter housing.

CCW

CCW

CC

Land Pride Cutter Blade Parts

Part No.

Part Description

820-168C

CUTTER BLADE 1/2 x 4 x 29 CCW (CTR)

820-169C

CUTTER BLADE 1/2 x 4 x 23 CCW (RH WING)

820-170C

CUTTER BLADE 1/2 x 4 x 23 CW (LH WING)

802-277C

BLADE BOLT 1 1/8-12 x 3 7/16 WITH KEY

803-170C

NUT HEX TOP LOCK 1 1/8-12 PLATE

804-147C

WASHER FLAT 1 HARD ASTMF436 PN

Section 5:

Maintenance & Lubrication