Land Pride RCM6015 User Manual

Page 18

16

Section 1: Assembly and Set-up

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

8/28/08

Land Pride

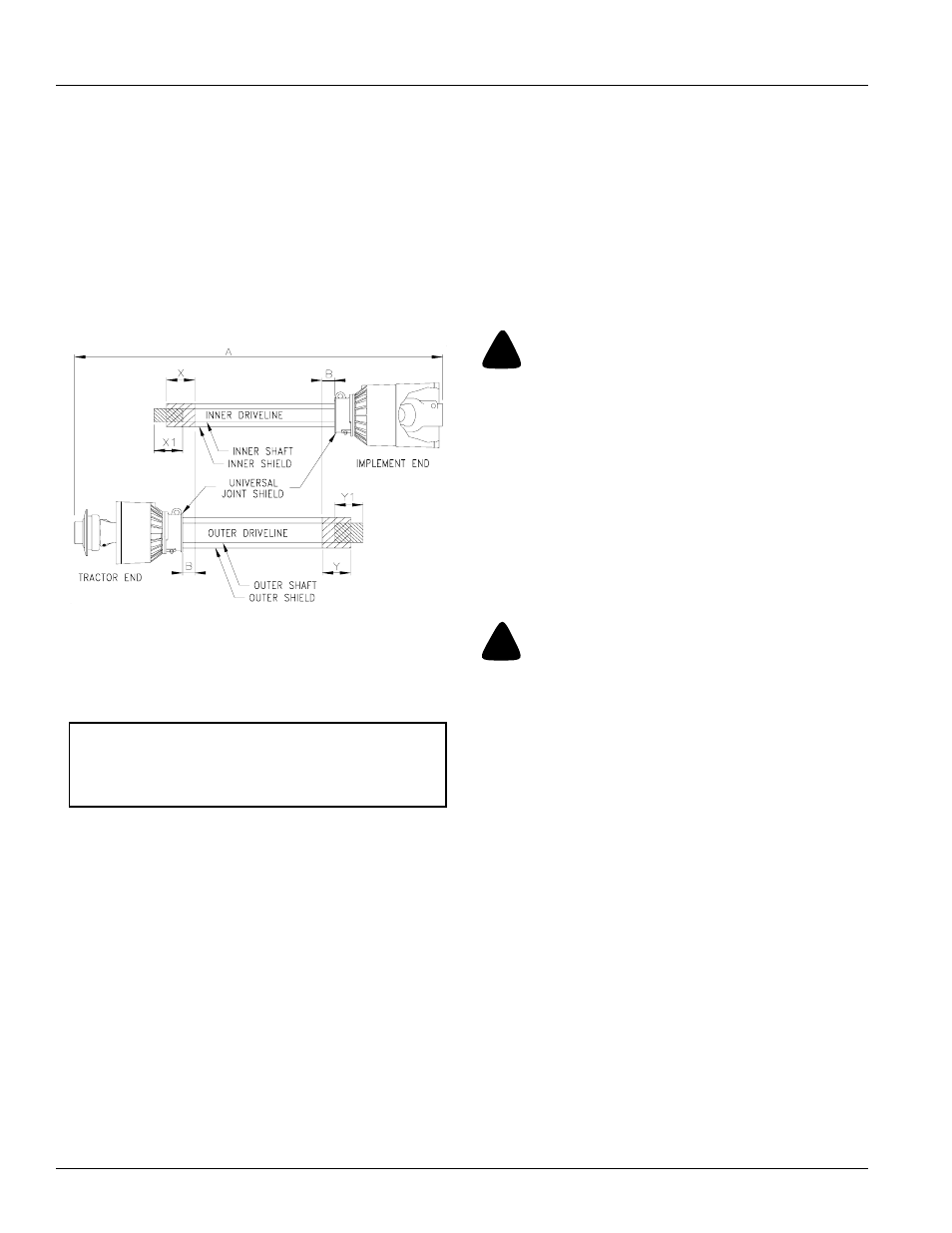

d. Cut off inner shield at the mark (“X” dimension).

Cut the same amount off the inner shaft (“X1”

dimension). Repeat cut off procedure (“Y” & “Y1”

dimensions) to the outer driveline half.

e. Remove all burrs and cuttings.

f. Apply multi-purpose grease to the inside of the

outer shaft and reassemble driveline.

g. Attach inner driveline yoke end to the divider

gearbox shaft.

h. Attach outer driveline yoke end to the tractor's

shaft.

PTO Driveline Shortening

Figure 1-11

4.

The driveline should now be moved back and forth to

insure both ends are secured to the tractor and cutter

PTO shafts. Reattach any end that is loose.

5.

Refer to Figure 1-10 on page 15. Secure chains (#6)

on driveline (#5) around hitch clevis rod to restrict

driveline outer shield from rotating. Re-latch safety

chain to driveline guard.

6.

Attach safety chain located on the other end of the

driveline (#5) to the cutter’s main frame to restrict

driveline inner shield from rotating. Re-latch safety

chain to driveline guard.

Hydraulic Hook-up

The required number of duplex outlets at the tractor is

dependent upon how the cutter is set-up.

The standard cutter is equipped with three hydraulic

cylinders with one in the center for lifting the cutter and

one on each wing for folding the wings simultaneously.

All three cylinders are set-up for single action

(one-way) operation.

22165

IMPORTANT: Two small chains are supplied with

each driveline. These chains must be attached to

the outer and inner driveline shields and to the cutter

deck or hitch to restrict the shields from rotating.

Each duplex outlet on your tractor can perform only one

operation. One outlet is needed for lifting the cutter and

one for lifting the wings simultaneously. A third outlet is

required if the wings are lifted independently. This will

also require replumbing the hydraulics to the wing

cylinders.

Your Land Pride dealer can help you determine the best

configuration that will match your needs and your tractor

capabilities. Optional control valve kits are available if the

tractor does not have the required number of duplex

outlets. For additional information, See Hydraulic Outlets

on page 11

!

DANGER!

Hydraulic fluid under pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin, it must be treated by a

doctor within a few hours or gangrene may result.

Refer to Figure 1-10 on page 15:

1.

Route cylinder hoses (#7) through hose support loop

and connect to tractor remote outlets.

2.

Cycle hydraulic system by raising and lowering center

deck cylinder and wing fold cylinders. It may be

necessary to purge the hydraulic system of trapped air

if operation is sluggish.

!

WARNING!

Be sure center deck and wings are lowered to the ground and all

hydraulic pressure is relieved before disconnecting any lines or

pipes between the Rotary Cutter and tractor hydraulic system.

The system may be purged as follows:

a. With wings lowered to the ground and hydraulic

pressure relieved, loosen hydraulic hose fitting at

each wing cylinder slightly to allow fluid to escape.

b. Slowly activate tractor control valve to purge any

trapped air from the system.

c. Tighten each fitting.

3.

The center deck lift cylinder is purged in the same

manner as the wing cylinders. The cutter must be

resting on the ground and all hydraulic pressure

relieved before loosening hose fitting as described in

2a above.

4.

Check driveline for adequate clearance under all

ranges of cutter height. With driveline shaft attached

to the tractor, slowly raise and lower cutter to its

upper and lower limits while observing clearances

between hitch and driveline. Adjust tractor drawbar

height and/or length if driveline interferes. See

Figure 1-1 on page 11 for correct drawbar

dimensions.