Commercial pool heaters, Installation, Continued – Lochinvar F0600187510 User Manual

Page 26: Combustion air fan adjustment (for startup), Connecting to gas supply, Gas pressure test

Commercial Pool Heaters

INSTALLATION

Continued

TABLE H

Outdoor Vent Cap Kits

Input

Btu/hr

Outdoor Vent Kit*

500,000

ODK3075

650,000

ODK3076

750,000

ODK3076

990,000

ODK3077

1,260,000

ODK3078

1,440,000

ODK3079

1,800,000

ODK3080

2,070,000

ODK3080

* These kits include an outdoor vent cap and gasket.

Flue gas condensate can freeze on exterior walls or on the vent cap.

Frozen condensate on the vent cap can result in a blocked flue

condition. Some discoloration to exterior building or pool heater

surfaces can be expected. Adjacent brick or masonry surfaces should

be protected with a rust resistant sheet metal plate.

The Outdoor Vent Cap Kit

The optional outdoor vent cap kit is available from the pool heater

manufacturer. The outdoor cap part numbers are listed by input

size. See TABLE–H for kit numbers.

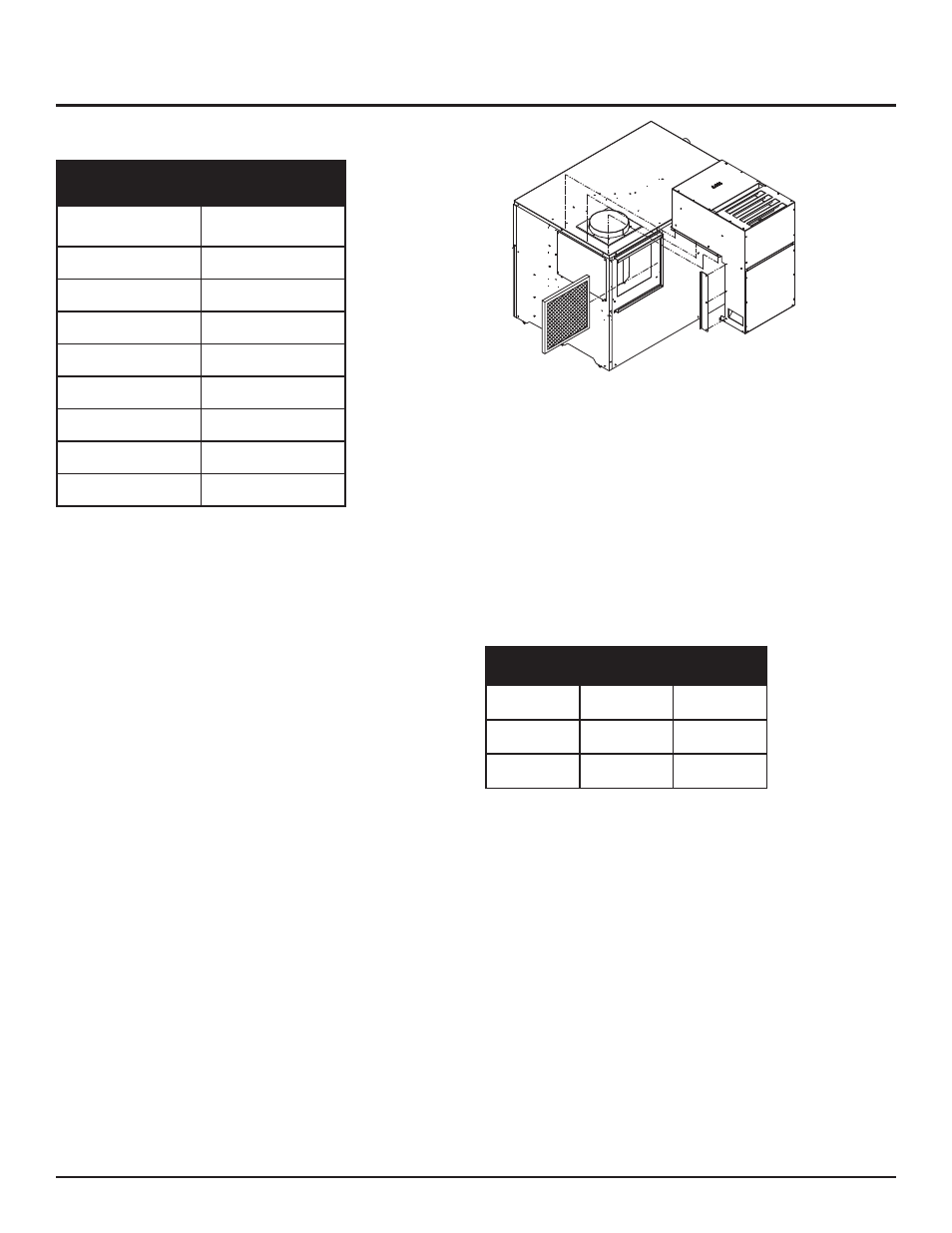

Install the outdoor vent cap on the rear of the pool heater, see

Figure 27.

The air filter bracket will need to be rotated as shown in Figure 27

to allow proper access to the filters with the outdoor vent cap in

place.

The 3-Way Valve Cover Installation

The 3-way bypass valve requires a cover for outdoor use. This cover

is provided with the outdoor vent kits listed in Table-H. See

page 31 for 3-way valve cover installation instructions.

Combustion Air Fan Adjustment (for

startup)

For startup, the combustion air fan shutter may require adjustment.

Should the combustion air fan shutter need adjusting refer to the

Adjusting Differential Air Pressure instructions located under the

Cleaning and Maintenance section on page 49 of this manual.

Note: The manifold gas pressure can affect the differential air

pressure. Once the combustion air fan shutter has been adjusted,

confirm manifold gas pressure as described in the Gas Manifold

Pressure Adjustment section on page 30 of this manual.

Figure 27 – Outdoor Vent Cap Installed on Rear of Pool Heater

CONNECTING TO GAS SUPPLY

Only supply gas type specified on the pool heater’s rating plate. This

pool heater is orificed for operation up to 2000 feet altitude. If

installing above 2000 feet elevation, consult the pool heater

manufacturer.

INLET PRESSURE: Measure inlet pressure at the inlet pressure tap

located upstream of the combination gas valve(s).

See TABLE–I for maximum and minimum inlet pressures. Do not

exceed the maximum. Minimum inlet pressure is for the purposes

of input adjustment.

TABLE-I

Inlet Pressure

Maximum

Minimum

Natural Gas

10.5" w.c.

4.5" w.c.

LP Gas

13" w.c.

8" w.c.

MANIFOLD PRESSURE: Measure manifold pressure at the

pressure tap on the downstream side of the combination gas valves.

The gas regulator on the pool heater’s combination gas valves is

preset at the factory to supply proper manifold pressure for normal

operation. See TABLE–L, page 31 for net manifold pressure settings.

If you must adjust regulator pressure, follow the instructions under

Gas Manifold Pressure Adjustment, page 30. Do not increase

regulator pressure beyond specified pressure setting.

Gas Pressure Test

1. Disconnect the unit from the gas supply piping system

during any piping system pressure testing greater than

1/2 PSIG (3.5kPa)

2. Isolate the pool heater from the gas supply piping system by

closing a manual shutoff valve during any piping system

pressure testing that is equal to or less than 1/2 PSIG (3.5kPa).

3. Test all gas connections for gas leaks before placing the pool

heater in operation.

26