Scag Power Equipment SFW36-16BV User Manual

Page 25

21

R

Section 6

INSERT 0.015 FEELER GAUGE HERE

Clutch Air Gap Adjustment

Figure 6-4.

Tighten or loosen the adjusting bolt as needed to

3.

acheive the 0.015 inch airgap. See Figure 6-5.

Perform this operation at all three inspection

windows.

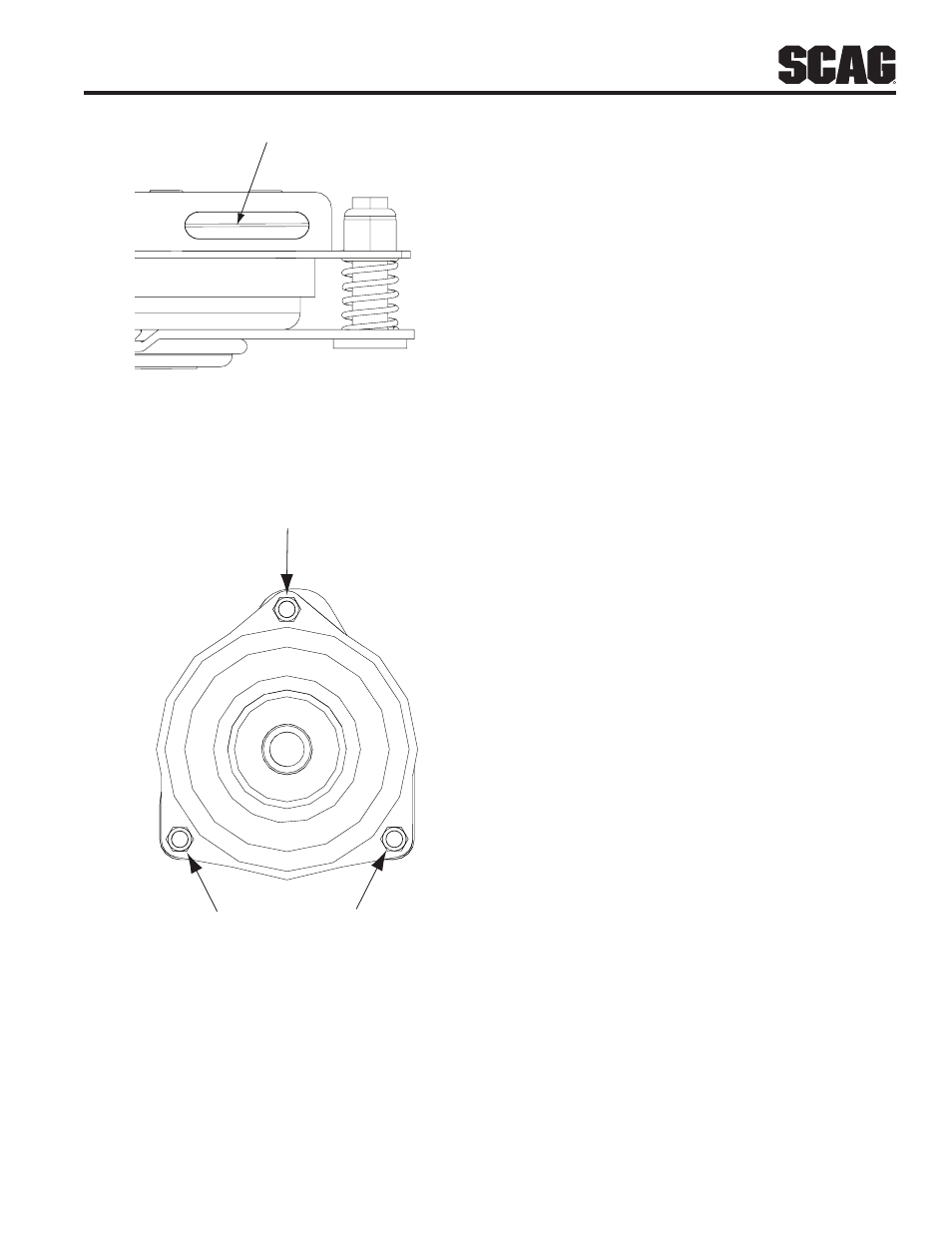

ADJUSTMENT NUTS

ADJUSTMENT NUTS

Clutch Air Gap Adjustment

Figure 6-5.

This adjustment should be done every 500 hours of

operation or annually, whichever comes first. In cases

where the machine is heavily used, airgap settings should

be checked more often.

If the air gap is too narrow, the clutch armature may drag

when disengaged, resulting in premature failure.

If the air gap is too wide, the clutch may be slow to engage

as the magnet must pull the armature in from a greater

distance.

See also other documents in the category Scag Power Equipment Gardening equipment:

- STT (129 pages)

- SWZ (36 pages)

- V-RIDE SVR48V-24FX (63 pages)

- SFZ52-19KA (20 pages)

- 79999 (84 pages)

- TURF TIGER STT61V-25CH-LP (76 pages)

- STC61-25CV-FR (110 pages)

- STC61V-25CV-FR (117 pages)

- STC SMTC-48V (31 pages)

- SMWC-61V (34 pages)

- STWC WILDCAT SMTC-48V (34 pages)

- WALK-BEHIND SWZ36A-16KAI (92 pages)

- STWC61V-27CV (120 pages)

- GC-STT-CS (28 pages)

- SCR (75 pages)

- GC-STWC-61V (20 pages)

- SCAG SCR (75 pages)

- SW48V-15KH (76 pages)

- GC-STC (19 pages)

- STT61V-35BV-SS (143 pages)

- TIGER CAT STC52V-27CV (80 pages)

- TURF TIGER STT61V-27KA (138 pages)

- FREEDOM Z SFZ61-28BS (69 pages)

- TURF TIGER STT61V-35BVAC (95 pages)

- V-RIDE SVR61V-29FX (65 pages)

- WILDCAT STWC61V-26KA-LC (122 pages)

- STWC (106 pages)

- STC (64 pages)

- SWZU (92 pages)

- TURF TIGER STT61V-31KB-DF (76 pages)

- STT61V-25KBD-SS (114 pages)

- 37621220 (18 pages)

- FREEDOM Z SFZ (109 pages)

- TIGER CAT STC52V-27CV-SS (116 pages)

- TURF TIGER STT61V-31EFI-SS (116 pages)

- TURF TIGER 6201 (28 pages)

- TURF TIGER STT61V-28CAT-SS (35 pages)

- SWU (40 pages)

- MODEL TS (14 pages)

- SWZV (105 pages)

- SSZ (41 pages)

- STT-31BSD (64 pages)

- TURF TIGER STT61V-29KB-DF (72 pages)

- TURF TIGER STT61V-25KBD (79 pages)