Spindle clutch adjustment – Southbend SB1046PF User Manual

Page 83

For Machines Mfg. Since 3/11

Turn-Nado

®

Gearhead Lathes

-81-

S E R V I C E

Spindle Clutch

Adjustment

This lathe uses a dual-clutch mechanism to drive

the spindle. The clutch assembly will need to

be adjusted if you have difficulty engaging the

forward or reverse spindle lever position or if the

chuck takes more than 3–4 seconds to reach full

speed when set at the highest spindle speed.

DISCONNECT LATHE FROM POWER before

performing this procedure. Failure to do so

could result in accidental startup, electrical

shock, entanglement or crushing injury, or

property damage.

DO NOT touch hot components. During use,

the clutch and other internal components can

become very hot. Wear heavy gloves or allow

components to cool before service.

Wear safety glasses throughout the entire

procedure. Oil may splash and spring-loaded

components may be thrown, resulting in injury

or loss of vision.

DO NOT rotate the spindle or input pulley by

hand while hands or fingers are inside the

headstock. Doing so may cause entanglement

and serious crushing injuries.

Support components while their mounting

fasteners are being removed. Components may

fall or swing outward if they are not properly

supported, resulting in crushing or laceration

injuries.

Required for Procedure

Qty

Wrench 4mm .........................................................1

Another Person .....................................................1

To adjust the spindle clutch:

1. DISCONNECT LATHE FROM POWER!

2. Move the spindle lever to the center (neutral)

position.

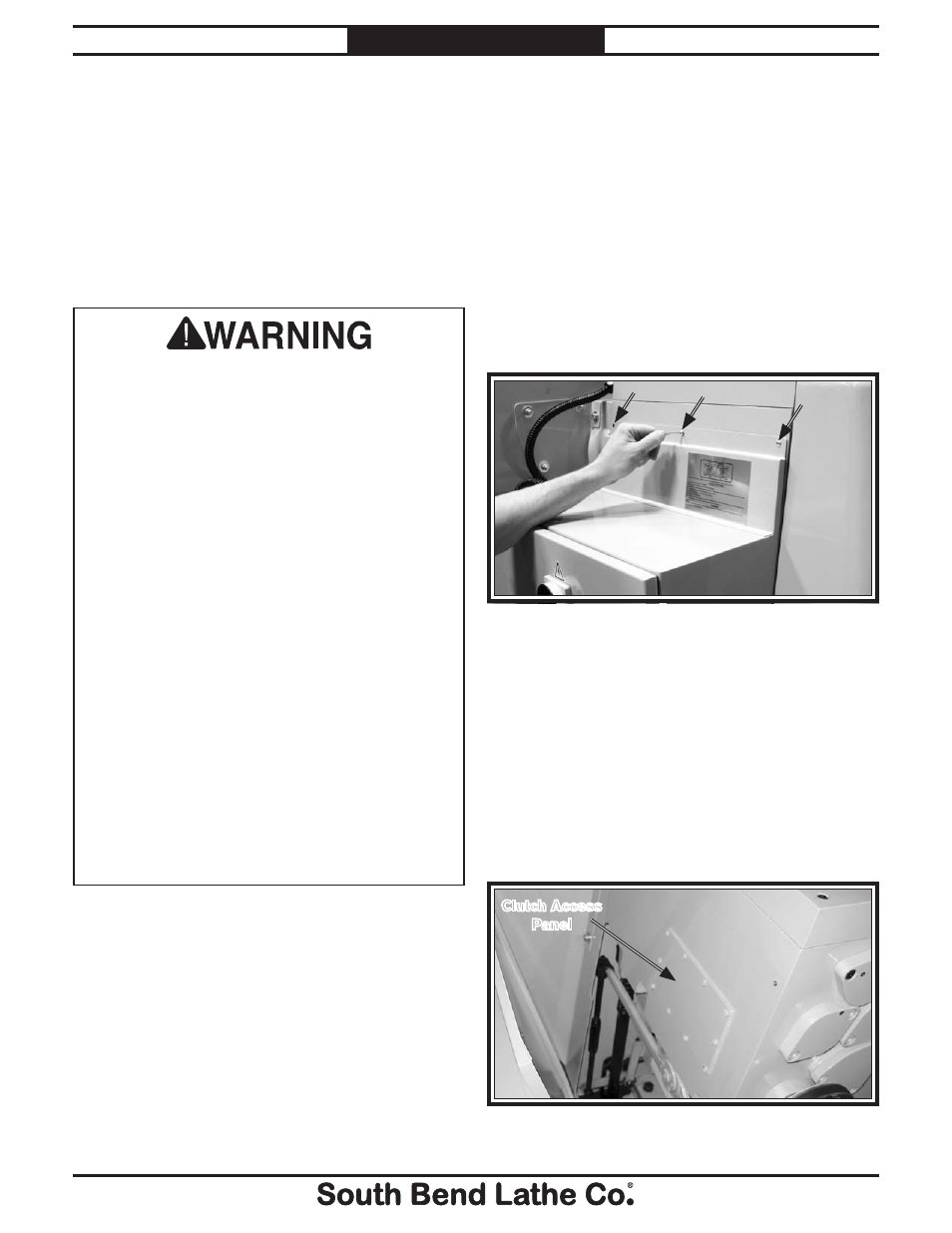

3. Have another person support the electrical

cabinet, then remove the three button-head

cap screws shown in Figure 122.

4. Tilt the cabinet out enough to allow access to

the clutch access cover, being careful not to

strain the lamp or chuck guard safety switch

cords. If necessary, remove these components

to prevent straining them.

Rest the cabinet on a stable support.

5. Remove the clutch access panel from the rear

of the headstock to expose the dual-clutch

mechanism (see Figure 123).

Figure 122. Removing electrical cabinet fasteners.

Figure 123. Spindle access panel.

Clutch Access

Panel