Lifting & moving – Southbend SB1046PF User Manual

Page 29

For Machines Mfg. Since 3/11

Turn-Nado

®

Gearhead Lathes

-27-

P R E P A R A T I O N

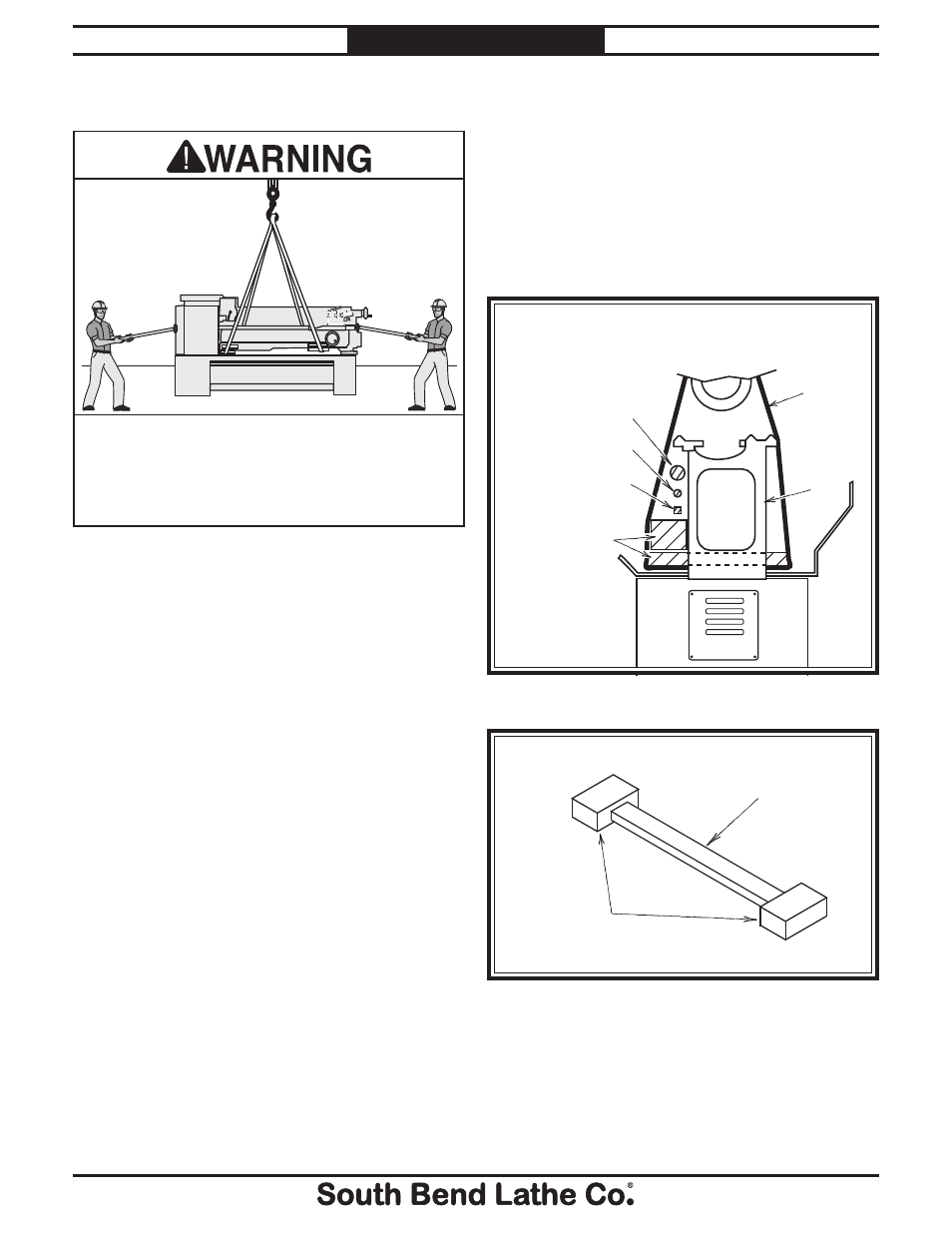

Lifting & Moving

This machine and its parts are heavy! Serious

personal injury may occur if safe moving

methods are not used. To reduce the risk of a

lifting or dropping injury, ask others for help,

and use power equipment and guide rods.

Do not attempt to lift or move this lathe without

using the proper lifting equipment (such as

forklift or crane) or the necessary assistance from

other people. Each piece of lifting equipment

must be rated for at least 25% more than the

shipping weight of your lathe to support dynamic

loads that may be applied while lifting. Refer to

Things You'll Need on Page 21 for details.

To lift and move the lathe:

1. Remove the shipping crate top and sides,

then remove the small components from the

shipping pallet.

2. Move the lathe to its prepared location while

it is still attached to the shipping pallet.

3. Unbolt the lathe from the shipping pallet

4. To balance the load for lifting, move the

tailstock and carriage to the extreme right

end of the bedway, then lock them in place.

Note: Before attempting to move the carriage,

make sure the carriage lock is loose, the half

nut is disengaged, and the power feed is

disengaged (feed ON/OFF lever).

5. Position hardwood blocking under each

end of the bed as shown in Figure 14.

This will keep the lifting straps away from

the leadscrew, feed rod, and spindle rod to

prevent bending them during lifting.

Note: Fasten a center support between the

hardwood blocking to that they will stay

spread apart and in place when lifting (see

the example in Figure 15).

Lifting

Strap

Lathe

Bed

Leadscrew

Feed Rod

Control

Rod

To Power Lifting Equipment

(Loooking at Lifting Setup from Tailstock End)

Hardwood Blocks

and Planks

Positioned as

Required to

Prevent Lifting

Straps from

Bending

Leadscrew

Figure 14. Lifting setup to keep straps from bending

leadscrew or rods.

Figure 15. Example of blocking center support.

Hardwood

Blocking

Center

Support