Feed belt replacement – Woodstock SHOP FOX W1756 User Manual

Page 45

-43-

W1756/W1757 43" Wide-Belt Sander

SE

RV

IC

E

Feed Belt Replacement

To remove the feed belt, use Figure

53 on

Page 44

and

match the number with the steps below:

1. Raise the table up so the conveyor belt is

approximately two-inches away from the sanding

roller or platen, and then

DISCONNECT THE SANDER

FROM THE POWER SOURCE!

2. Remove the gearbox mounting bracket, and with an

assistant's help, slide the motor and gearbox from

the roller shaft and lower it to the floor.

Note: Do not loosen the two vibration dampener

washers shown in Figure

53

.

3. Remove two table height limit switches.

4. Remove both lower access panels.

5. Remove the left and right table guides.

6. Using a permanent marker, mark all four lead screw

flange positions (

Figure

52

), and remove all hex

bolts from the flanges.

7. Insert two 2x4x8' wooden studs under the table to

support the table, and then (with help) lift the table

slightly and move it out of the rear of the machine.

8. Disconnect the limit switch, remove all mounting

screws, and remove the emergency stop push-panel

assembly.

9. Turn both tracking adjustment bolts counter-

clockwise five turns, remove one roller support, and

slide the drum out of the table assembly.

10. Remove the old feed belt, inspect rollers, bearings,

and table for wear and replace as required.

11. Install the new feed belt.

Note: The belt is non-directional.

12. Install the front roller, the roller support, and turn

both tracking adjustment bolts clockwise equally so

the conveyor belt becomes taught and does not hang

loose. DO NOT OVERTIGHTEN the belt.

13. With a helper, install the table from

the rear in a similar fashion as it was

removed.

14. Install the table guides and the left

and right lower access panels.

15. Align the lead screw flanges with the

marks made in

Step 6, and install the

hex bolts.

16. Install and adjust the table height

limit switches (refer to

Page 34

).

17. With a helper, install the gearbox,

vibration dampener washers, and

mounting bracket.

18. Install the emergency stop push panel

assembly and the limit switch.

19. Start the conveyor motor and turn the

conveyor tracking bolts as required

until the conveyor belt tracks straight

without loading up on one side of the

table.

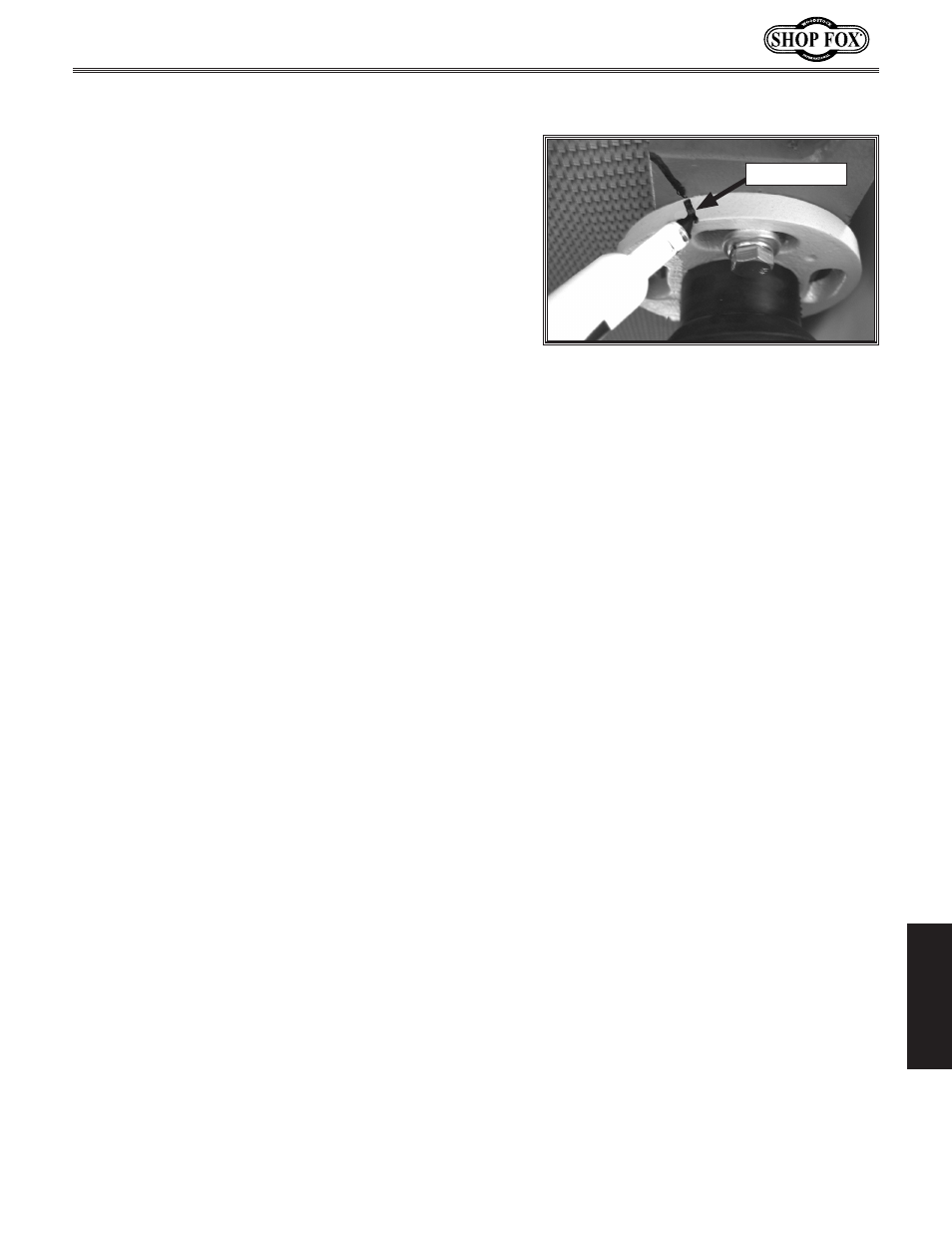

Figure 52. Marking lead screw for

reassembly.

Timing Mark