Adjustable apron stop system, Carriage stop – Southbend South Bend EVS Toolroom SB1012 User Manual

Page 44

-42-

For Machines Mfg. Since 7/09

EVS Toolroom Lathes

O P E R A T I O N

Adjustable Apron Stop

System

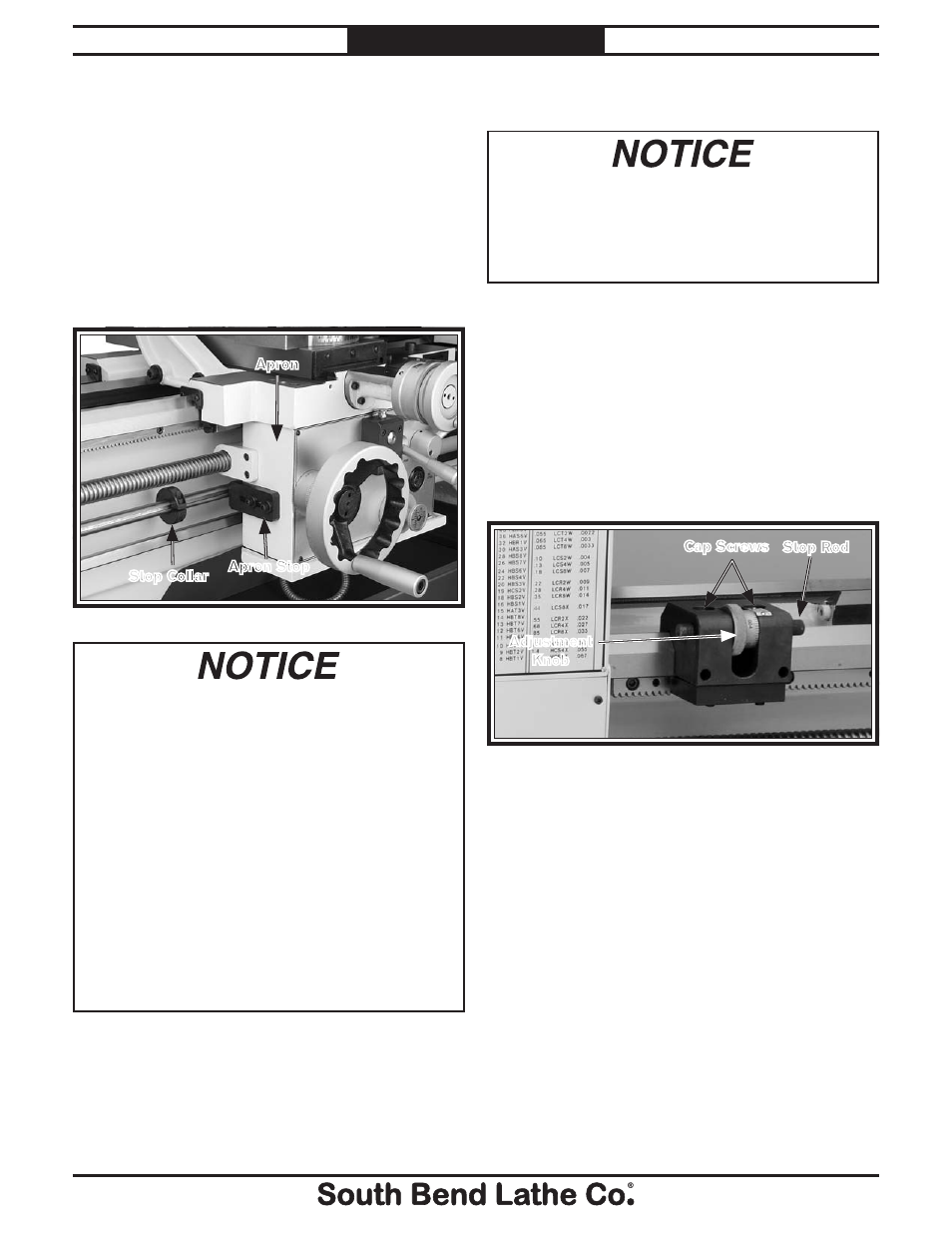

Use the adjustable apron stop collar (shown in

Figure 75) to set the location where the carriage

will be disengaged by the feedrod friction clutch.

When the adjustable apron stop contacts the stop

collar during a carriage feeding operation, the

clutch disengages the feedrod from the apron and

the carriage movement stops.

Figure 75. Adjustable apron stop and collar.

Apron Stop

Stop Collar

Apron

The adjustable apron stop system is designed

to stop the longitudinal carriage movement

at optional locations when the feedrod is

engaged.

When the leadscrew is engaged for threading

operations, the adjustable apron stop system

will not disengage the leadscrew—you must

move the half nut lever instead. Otherwise,

the carriage can crash into the chuck, or if it

contacts the stop, the leadscrew shear pin will

break.

Before doing any threading operations, make

sure to loosen the stop collar so it slides

freely on the feedrod.

Carriage Stop

The carriage stop on this lathe will NOT

automatically stop the carriage or disengage

the power feed! Failure to heed this notice

could result in the carriage crashing and

causing severe machine or property damage.

Use the carriage stop as a guide to help judge

when to stop the carriage movement.

Tools Needed

Qty

Hex Wrench 8mm ................................................. 1

To adjust the carriage stop:

1.

DISCONNECT LATHE FROM POWER!

2.

Loosen the cap screws shown in Figure 76.

3.

Use the carriage handwheel to position the

carriage/cutting tool at the stop point you

want to set (typically the maximum distance

the carriage can travel before there is a

crash).

4.

Position the carriage stop so the rod is

firmly against the carriage, retighten the

cap screws loosened in Step 2, and use the

adjustment knob to fine tune the position of

the stop rod.

5.

Move the carriage away from the stop rod,

then move it back against the stop rod and

verify that tooling will not make contact with

chuck, jaws, or other components (rotate the

chuck by hand to verify rotational clearance).

Figure 76. Carriage stop.

Stop Rod

Adjustment

Knob

Cap Screws