Spindle break-in – Southbend South Bend EVS Toolroom SB1012 User Manual

Page 23

For Machines Mfg. Since 7/09

EVS Toolroom Lathes

-21-

P R E P A R A T I O N

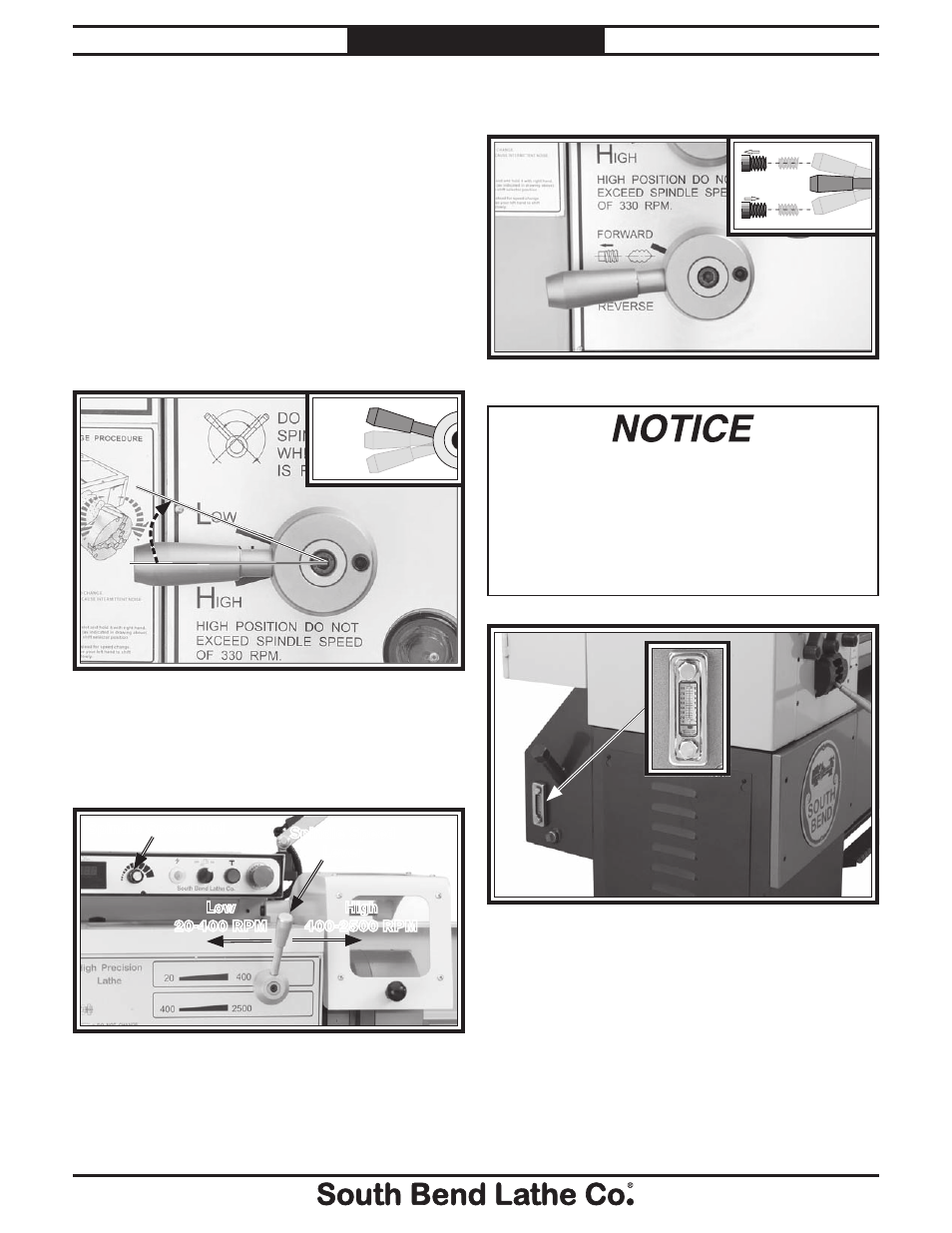

Do not leave the lathe unattended during the

break-in period. Make sure that you keep a

close eye on the headstock oil thermometer

(Figure 29) on the oil reservoir. If the

headstock oil temperature reaches 160°F,

shut the lathe down and let the system cool

before resuming break-in.

Figure 29. Oil temperature thermometer.

4.

Move the feed direction forward/reverse lever

(Figure 28) to the neutral position.

Figure 28. Feed direction lever in neutral position.

F

ORWARD

R

EVERSE

N

EUTRAL

Spindle Break-In

It is essential to closely follow the proper break-in

procedures to ensure trouble-free performance.

Complete this process once you have familiarized

yourself with all instructions in this manual and

completed the test run.

To complete the spindle break-in:

1.

Successfully complete the Test Run

procedure beginning on Page 17.

2.

Move the gearbox range lever to low range

position, as shown in Figure 26.

Figure 26. Gearbox range lever-break in.

L

OW

N

eutral

H

IGH

3.

Turn the spindle speed dial (Figure 27) all

the way counterclockwise to the minimum

speed, and move the spindle speed range

lever to the low range.

Figure 27. Spindle speed controls.

Low

20-400 RPM

High

400-2500 RPM

Spindle Speed Dial

Spindle Speed

Lever